What Does a Printed Circuit Board Do?

For manufacturing and industrial companies, every piece of equipment on the floor plays a role in keeping production moving. When one machine goes down, entire operations can stall, leading to delays, higher costs, and frustrated teams. In many cases, the issue traces back to the electronics side, specifically, the printed circuit board (PCB).

Understanding what a printed circuit board does, the types of PCBs your equipment may use, and how to respond when one fails can help your company reduce downtime and protect productivity.

What Does a PCB Do?

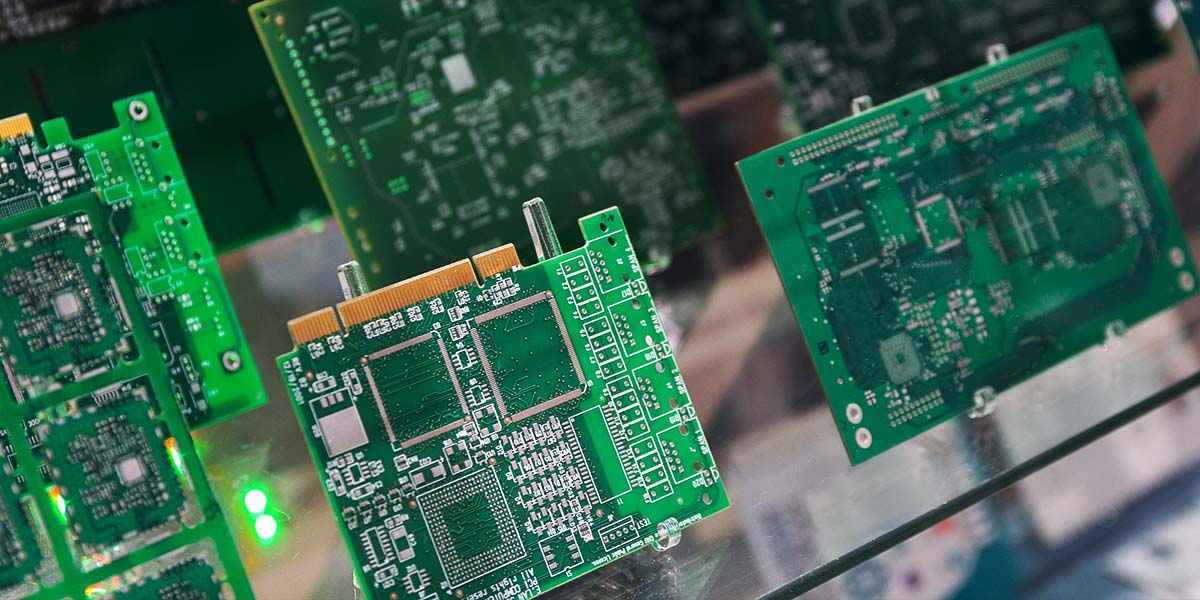

A PCB is the foundation of almost every modern electronic system. It supports electronic components and provides the pathways that allow electronics to connect and communicate. PCBs regulate processes, control power distribution, and support automation in industrial equipment. They connect sensors, controllers, and actuators, allowing automated systems to communicate and perform tasks accurately. They are essential for robotics, quality control systems, and process automation.

PCBs use layers of conductive copper to create the pathways that allow electricity to flow where it’s needed. Many components are attached using surface-mount technology (SMT), which places parts directly on the board’s surface to save space and improve performance. This design makes them essential to nearly every modern electronic device, from phones and tablets to industrial power supplies and automation equipment.

Common Applications by Industry

PCBs are used in nearly every sector where electronics play a role. While the designs may vary, their function remains the same — create a reliable foundation that allows machines and devices to perform complex tasks:

- High-tech and computing: The high-tech industry depends on PCBs for processing, communication, and power distribution. They are central to servers, data storage systems, networking devices, and consumer technologies like smartphones and tablets. To achieve compact designs, these devices use multilayer PCBs with dense networks of vias that link circuits across layers.

- Aerospace and defense: Boards in this sector are engineered to withstand extreme temperatures, vibration, and high radiation levels. They power avionic systems, radar equipment, satellite technology, and communication systems.

- Automotive: Modern vehicles are essentially computers on wheels, and PCBs are the backbone of their electronic systems. They are used in engine control units, navigation, advanced driver assistance systems (ADAS), and electric vehicle battery management.

- Industrial equipment and manufacturing: In industrial environments, PCBs handle much more than everyday consumer electronics. They are built to withstand high voltages, constant vibration from heavy machinery, and extreme temperature changes. This durability makes them a trusted choice for demanding equipment such as manufacturing drills, presses, measurement tools, and robotics.

Types of Printed Circuit Boards

Different applications call for different PCB designs, and the type of PCB your equipment uses can directly affect its reliability, performance, and lifespan.

Single-Sided PCBs

Single-sided boards place all electronic components on one side and all copper traces on the other. Their simple design makes them easy to produce. These boards are often used in equipment with straightforward control functions such as power supplies, calculators, and basic monitoring systems.

Double-Sided PCBs

Double-sided PCBs have components mounted on both sides of the board. They are common in industrial applications that require greater processing power and more compact layouts, such as motor drives, HVAC controls, and industrial instrumentation.

Multilayer PCBs

Multilayer PCBs consist of three or more copper layers stacked together. This design supports high-density connections while keeping the overall board compact. They are essential for advanced applications like robotics, telecommunications, and automated production lines where speed, precision, and reliability are crucial.

Rigid, Flexible, and Rigid-Flex PCBs

Three other types of PCBs include:

- Rigid PCBs: Built from strong materials, rigid PCBs maintain their shape, making them ideal for heavy-duty industrial machines that face demanding conditions.

- Flexible PCBs: Made with bendable materials, flexible PCBs can fit into tight spaces or equipment with moving parts. They are frequently used in wearable technology, aerospace systems, and industrial sensors.

- Rigid-flex PCBs: Combine rigid and flexible features, balancing strength and adaptability. These hybrid boards are widely used in equipment that requires durability and compact design, such as medical devices or industrial control systems.

What to Do if a PCB Needs Repairs

Even the most durable PCBs eventually wear down. High temperatures, vibration, dust, and long hours of operation take their toll, leading to failures that can bring production to a standstill.

Signs a PCB May Be Failing

Recognizing the warning signs early is one of the best ways to limit disruption. A failing PCB often shows symptoms long before it stops working completely.

- Unstable or inconsistent machine performance: Equipment that runs inconsistently or delivers irregular results.

- Visible damage: Burn marks, corrosion, or cracks on the board.

- Frequent system resets or shutdowns: Systems that restart unexpectedly or fail to stay powered.

- Complete failure: Equipment that refuses to power on at all.

Repair vs. Replacement

When a PCB stops performing correctly, the next step is to decide whether repair or replacement makes the most sense. Both options have advantages depending on the condition of the board and the needs of an operation:

- Repair: When the damage is limited, such as a failed capacitor or connector, repairing is often the fastest solution. Skilled technicians can restore the board to working order without replacing the entire system.

- Replacement: If the PCB is severely damaged, outdated, or no longer meets performance needs, replacement may be the more reliable long-term solution.

Key Preventive Maintenance for PCBs

The best way to minimize unexpected downtime is by preventing PCB issues before they escalate. Regular care keeps boards in better condition and can help extend their lifespan:

- Routine inspections: Schedule checks for boards in critical equipment to identify early signs of wear.

- Controlled environments: Maintain stable temperatures and reduce vibration where possible.

- Protective measures: Shield boards from dust, moisture, and chemicals that accelerate damage.

By addressing problems early and practicing preventive care, companies can extend PCB lifespans, minimize downtime, and keep production running efficiently.

What Should You Do If Your PCB Needs Repairs?

If a PCB fails, companies should assess whether repair or replacement is more cost-effective. Repairs can resolve localized issues quickly, while replacement can help with outdated or severely damaged boards.