Gear Pump Repair Service

The United States spends billions of dollars on equipment repair annually, and for good reason. Equipment is the lifeblood of many businesses, and nonfunctional equipment can quickly bring production to a standstill and send profits plummeting. Estimates from Sweden, for example, suggest that downtime costs amount to 23.9 percent of the total cost of manufacturing.

Fortunately, a quality repair service can get your equipment back up and running in no time. If you have gear pumps in need of repair, Global Electronic Services can help.

Gear Pump Repair and Maintenance Services

One of the most common types of equipment we see in the service center, gear pumps utilize a mesh of two or more gears that displace fluid within an internal cavity. Just like all gears, they are subject to wear, especially if the fluid has become contaminated.

Our Gear Pump Repair Services

Our hydraulic gear pump repair services include the following elements:

1. Case Seal Inspection and Replacement

When we perform a hydraulic gear pump repair, we inspect the case seals for inspection and replace any worn or leaking seals as needed. If the case seals have cracked or dried out, they may be leaking transmission fluid or gear oil. We inspect these seals meticulously and have ready replacements on hand if needed, so we can help keep your equipment running effectively.

2. Drive and Idler Gear Service or Replacement

During gear pump repairs, we also inspect the drive and idler gears to determine whether or not they require service or replacement. In a gear pump, there are two sets of gears, the ones that drive the pump’s motion and the ones that are driven. The rotor, or drive gear, drives the motion, and the idler gears are driven. Since these gears power the pump, faults with either of these types of gears can impede the pump’s function. Therefore, we service or replace the gears to help improve your pump’s performance.

3. Pressure Port Inspections

During a gear pump repair, we also inspect the pressure ports to ensure they are functioning as they should. The small, circular pressure ports are located where the different gears mesh. High and low-pressure ports serve different functions in the gear pump, and malfunctions can disrupt the delicate balance of pressure and cause it to lose its effectiveness. We inspect the pressure ports for issues and provide service as necessary.

4. Inspection and Replacement of Bushings

As needed, we also inspect and replace bushings during gear pump repairs. Too much pressure in the gear pump can cause loss of lubrication and excess wear and tear on the bushings that support the gear journals.

Over time, this wear and tear cause the bushings merely to spin in the housing rather than function normally — and when the bushings can’t function, inefficiency or pump breakdown may result. When we inspect bushings, we can check for contamination wear and other factors that indicate the bushings need to be replaced.

5. Replacement of Oil Seals

When we perform gear repairs, we also replace any damaged oil seals. Oil seals are used to stop oil and grease from leaking out from between the shaft and the housing. Worn-out or cracked oil seals can lead to oil leaks that impede the efficiency of the gear pump. They can also allow contaminants like dirt and debris to enter the pump and collect on the shaft and bearings, causing damage. We replace worn-out oil seals to ensure your company’s equipment will not leak oil or become contaminated by foreign matter.

6. Inspection and Machining of Shafts

During gear pump repairs, we inspect shafts for wear as needed. Excessive torque inside the rotor of the gear pump can cause the shaft to bend, break or displace itself, potentially shearing off screws. Damage to or displacement of the shaft can end up resulting in casing wear, head wear and eventual rotor damage as well. We can inspect the shaft to assess any damage and then use machining to make repairs.

7. Replacement of Bearings

As we work on your gear pump, we also replace any worn-out or damaged bearings. The bearings in a gear pump are necessary to reduce friction and ensure smooth operation. Worn-out bearings can increase friction and stress on gear pump components and cause the pump to lose its ability to generate pressure and operate effectively. They may also cause the pump to consume excessive amounts of energy. Factors that increase bearing wear include:

- Poor lubrication

- High operating temperature

- Vibration

We replace worn bearings to ensure your gear pump will be capable of robust, efficient performance.

8. Inspection and Repair of Pressure and Return Ports

During the repair process, we also inspect and replace pressure and return ports as necessary. As we discussed briefly above, pressure ports are essential for maintaining the balance of pressure in the gear pump, and the return port allows for a low-pressure return of fluid to the gear pump’s reservoir. We can inspect both types of ports and replace them if either has reached the end of its lifespan.

Frequently Asked Questions About Our Gear Pump Services

Below are some of the commonly asked questions about gear pumps and gear pump services:

1. Why Is There Little to No Lift From My Hydraulic Cylinder?

One possibility is that the gear pump is faulty. Gear pumps can malfunction for a variety of reasons, like bent and broken shafts or cracked seals — one likely possibility, in this case, is internal leakage. Another possibility is a malfunction within the cylinder itself, or the relief valve cartridge may be worn. If you’re having trouble with your cylinder’s lift, let us know about the issue, and we’ll be happy to take a look.

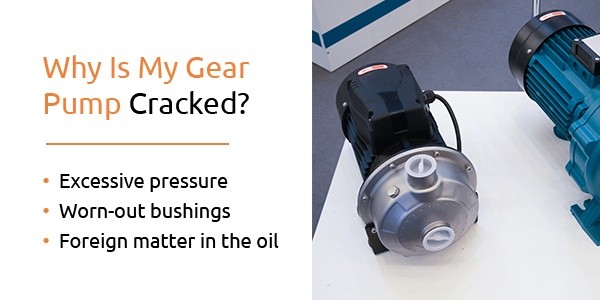

2. Why Is My Gear Pump Cracked?

If your gear pump has developed a crack, one of three causes is likely to be the culprit:

- Excessive pressure: Pressure buildup can cause the center housing of the gear pump to crack. This situation might occur because of an excessively high relief valve setting or a malfunction in the valve.

- Worn-out bushings: If the bushings are worn out, the gears may cut into the sides of the pump body and sever a piece of aluminum. The chunk of aluminum may then come between the gears, force them apart, and crack the body.

- Foreign matter in the oil: Foreign matter in the oil can also damage the pump body. A small bearing, a rag or some metal pieces may get into the oil, force the gears apart, and crack the body. Flushing the system is an excellent way to prevent scenarios like this from occurring.

3. Can the Components of a Gear Pump be Repaired?

Typically, no. As the individual components wear down, they will need to be replaced. Much of the repair work done on hydraulic gear pumps involves replacing worn-out or broken parts.

4. What Is the Importance of Suction Pressure?

Suction pressure forces fluid into the inlet of the pump. This pressure can come from air pressure or from the fluid above the suction port. Maintaining this pressure despite friction is important — a drop below the vapor pressure of the fluid can result in cavitation.

5. What Is Cavitation?

Cavitation occurs when the pressure in the pump is too low to prevent the fluids from becoming gas. Gas molecules take up more space than liquid molecules, so the vapor bubbles create a cramped space and a loss of fluid flow. And when the gas turns back into a liquid, it can create significant shock in the pump, creating pits or caves in the metal and over time resulting in complete system failure. If you suspect cavitation in your gear pump, get in touch with us to discuss your options.

Global Electronic Services Gear Pump Repair and Maintenance

For hydraulic pump repair and maintenance services, Global Electronic Services is the only place you need to go. We perform high-quality gear pump repair at a price you can afford.

Find out how to get started by contacting us online for a free quote or calling us at 877-249-1701. We’re ready to handle all your gear pump service needs.