Fuses

Fuses are devices that install into an electrical circuit to protect components from the damaging effects of overcurrent, like an electrical shock or a fire. Fuses typically contain a low-resistance wire or metal strip to close the circuit when encountering a load greater than its rating. They react to electrical conditions such as circuit overloads, faults and shorts.

When a mismatched load occurs, the wire inside the fuse melts because of the heat generated by the current. The melting prompts the fuse to disconnect the power supply from the connected system.

-

OMRON

OMRONOmron Basic / Snap Action Switches A2A-4R Repair Service and Sales

- Model #:

- A2A-4R

- Part #:

- A2A-4R

-

OMRON

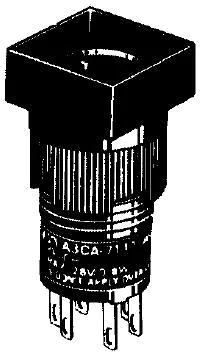

OMRONOmron Switch Contact Blocks / Switch Kits A3CA-7011 Repair Service and Sales

- Model #:

- A3CA-7011

- Part #:

- A3CA-7011

-

OMRON

OMRONOmron Switch Cases / Switch Covers A22Z-EG1 Repair Service and Sales

- Model #:

- A22Z-EG1

- Part #:

- A22Z-EG1

-

Allen-Bradley

599-NK3: Allen-Bradley Neutral Fuse Kit

- Model #:

- 599-NK3

- UPC #:

- 66207466025

- Part #:

- 599-NK3

- New/Surplus $ 208

- Refurb. Price $146 Save up to $ 62

- Repair Price $104 Save up to $ 104

-

GE Controls

GE Controls55A212942P6RB: GE Controls FU-4.8KV/6R VAC BOLT

- Model #:

- 55A212942P6RB

- UPC #:

- 78317510712

- Part #:

- 55A212942P6RB

- New/Surplus $ 2992

- Refurb. Price $2094 Save up to $ 898

- Repair Price $1496 Save up to $ 1496

Types of Industrial Fuses

Fuses divide into either an alternating current (AC) or direct current (DC) category. The primary difference between these categories is a fuse’s ability to stop the arcs that form when the fuse blows. DC fuses are typically larger than AC fuses because of how they break the arc.

Fuse types include cartridge fuses, thermal fuses, rewireable fuses and others. They play critical roles in almost every industry and often have exclusive functions for specific parts. For example, automotive fuses have multiple rating types for various vehicle circuits.

Some examples of a fuse’s characteristics include:

- – Current rating: This rating is the maximum current a fuse can handle under normal conditions, typically measured in amperes at a specific temperature.

- – Voltage rating: This measurement is the maximum voltage a fuse can tolerate when an overcurrent occurs.

- – Breaking capacity: The breaking capacity is the amount of current a fuse can break without destroying itself, also called the interruption rating.

- – Response characteristic: This measurement is the speed at which a fuse blows.

Fast fuses have quicker response times for components especially susceptible to overcurrent. Slow burn fuses work well in systems that can withstand more current. Most fuses contain markings indicating their current and voltage ratings.

Benefits of Using Fuses

Fuses have been the most efficient and economical method of protecting electrical circuits since the late 19th century. They play critical roles in electrical systems found in lighting circuits, motors, transformers and branch circuits of distribution lines in residential, commercial and industrial applications.

The primary benefits of fuses include:

- – They are the least expensive method for protecting an electrical circuit.

- – Fuses require no maintenance.

- – They are easy to install and replace.

- – They can interrupt overcurrent without causing noise, smoke or flames.

Despite the advantages, fuses sometimes look highly similar and can be challenging to distinguish when troubleshooting. In addition, your company may see lengthy downtime in manufacturing or production while waiting to replace a broken fuse.

How to Tell When a Fuse Needs Replacing

Most fuses remove easily from their holder manually or with the assistance of a screwdriver. Upon inspection, if the fuse wire has a visible gap or contains a dark smear inside the glass, the fuse is blown and requires replacement. If there are no visual indications, a multimeter can measure the fuse’s resistance, determining whether it’s still usable or blown.

Find Industrial Fuses at Global Electronic Services Today

At Global Electronic Services, we supply a broad range of fuses to meet the needs of your company’s specific operation. If you require assistance in selecting the correct fuse for your facility, call us at 877-249-1701 today or contact us online for help.