AC & DC Motor Repair

Our AC & DC Motor Repair Services

AC/DC Machine | AC/DC Testing Details | AC & DC Drive Repair

AC/DC Motor Repair

When you work with industrial equipment all day, you rely heavily on quality, high-performing AC and DC motors. Motor failures can occur for many reasons, and the average failure rate across industrial facilities is about 3.4% per unit per year, with a range of variation – relatively low, but breakdowns will inevitably occur. If your motors require maintenance or break down, your company needs to be able to trust its repair shop for efficient electric motor servicing to get them up and running quickly.

Trusted Electric Motor Repair Shop

At Global Electronic Services, we offer an extensive range of AC/DC electric motor repair services. Let us show you how our industrial electric motor repair processes work and how they can benefit your company’s motors.

Rewinding

Few machine shops provide in-house rewinding, but we do. Over the years, we’ve fine-tuned our rewinding skills to ensure we can give you the best repair service possible. Our skilled winding technicians have the ability and equipment to rewind any kind of industrial motor including AC, DC, servo and spindle motors. Many motor shops only rewind above a certain horsepower or are limited to a specific type of motor. We do not operate under this constraint and can rewind all types, including random, concentric, lap, form coil and armature rewinds. Our ac and dc motor repair process is as follows:

- – We strip the windings, taking care to preserve their structural integrity.

- – Technicians carefully record and measure the wire size, span, turns and number of conductors within the motor coils as well as grouping and internal wiring.

- – We burn out coils using a pollution-controlled furnace at carefully regulated temperatures.

- – We remove bad coils and blast the core clean using non-destructive media to prevent excessive efficiency losses.

- – Motors that are highly contaminated with oil or grease within the laminations receive pressure-cleaning at a high temperature with an industrial alkaline-based degreaser.

- – A winding technician then makes new coils using only VFD-rated magnet wire. VFD-shielded wire is essential because motors that run with a VFD are subject to more electrical stress than motors that use a starter.

- – We install H-class insulation and then dip and bake the windings.

- – Motor windings undergo testing with an AWA analyzer both before and after the rewind process.

Bearing Changes

Many motor failures involve the bearings. The bearings, as their name suggests, bear much of the mechanical load in a motor. They must contend with significant friction and hold up under tremendous force. Because of these stresses, the bearings tend to wear out more quickly than other motor components. Bearing care is essential in a motor, and for this reason, it’s standard protocol for us to change the bearings on every repair we perform.

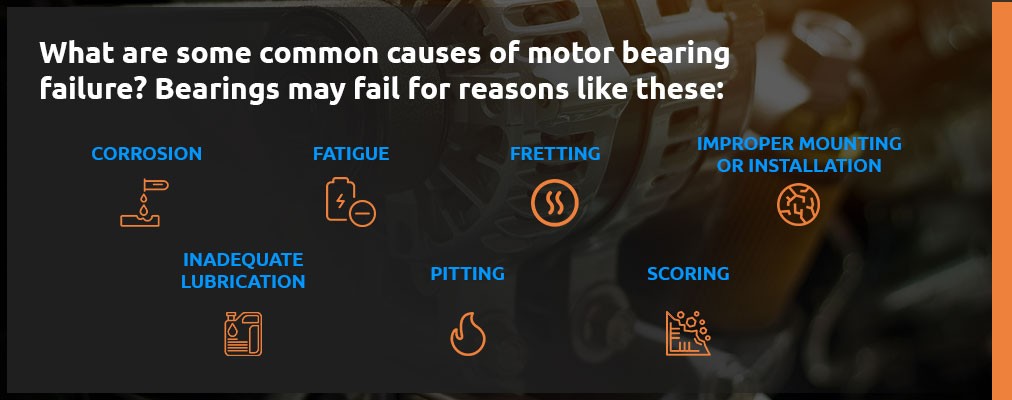

What are some common causes of motor bearing failure? Bearings may fail for reasons like these:

- – Corrosion: Corrosion occurs when water or other liquids such as acids come into contact with the bearing surfaces and lead to rust development. Fortunately, corrosion is often preventable with proper lubrication.

- – Fatigue: Fatigue happens when bearings run repeatedly under heavy loads. The repetitive heavy-duty use stresses the metal until it fails. Lack of lubrication can exacerbate fatigue and hasten failure.

- – Fretting: Fretting occurs when two different dry surfaces scrape repeatedly against one another. Somewhat preventable with proper lubrication, fretting can cause corrosion if it persists.

- – Improper mounting or installation: Improperly mounted bearings will likely crack if they fit too tightly. Cracks, in turn, can lead to higher operating temperatures and increase the likelihood of breakdowns.

- – Inadequate lubrication: Poor lubrication increases friction and causes excessive bearing wear and tear.

- – Pitting: Electric pitting occurs when the electric current flowing through the motor causes burning. It is particularly common in the presence of an air gap or excessive electrical loads.

- – Scoring: Scoring occurs when dirt and debris enter the motor and come into contact with the bearings. These particles scratch and scrape the bearings as they turn.

What problems do worn bearings cause? Worn or damaged bearings can have numerous adverse impacts on a motor and its performance:

- – Overheating: A worn or poorly lubricated bearing can increase friction and cause the motor to run hot, potentially shortening its lifespan and raising the risk of fire or failure.

- – High-frequency noise: Especially in servo motors, a dry bearing can cause a high-pitched squeak or whine. Sometimes, dust from the brake pads creeps into the bearing and soaks up all the lubrication, causing friction and noise.

- – Motor damage: A worn bearing can cause misalignments or put excessive strain on other motor components. These issues can lead to damage.

- – Catastrophic failure: Ultimately, if not addressed, a bearing problem can lead to a complete breakdown of the motor. A breakdown can halt productivity and necessitate time-consuming and expensive repairs, so you’ll want to try not to let a bearing issue reach this point.

How does changing a bearing work? The process is relatively straightforward.

First, the technician disassembles the motor to gain access to the bearings and enable any further repairs. This disassembly includes removing the fan housing and fan, taking out assorted nuts, washers and rods, and removing the motor caps to expose the bearings.

The technician may use a jaw-style puller or a bearing splitter to remove each bearing from the shaft. A bearing splitter tool puts consistent, even pressure on the bearing, and its slim design makes it ideal for small spaces where a jaw-style puller won’t fit. The bearing splitter can also be used with a hydraulic tool for an alternative removal method.

The technician then uses a micrometer to measure the diameter of the part of the shaft where the bearing sits. The measurement should be precise down to the thousandth of an inch. The technician will also likely make several measurements and then take the average to ensure the greatest accuracy. The inside of the bearing and the diameter of the motor housing get measured in the same way.

The new bearing goes into a bearing heater that will heat it to match the motor’s internal operating temperature. An induction magnet goes around it to spread out the heat, and a temperature probe reports the temperature. Heating the bearing helps it slide more easily along the shaft. If it gets stuck partway, the technician can use additional tools to press it into position.

All that’s left to do at this stage is to reassemble the motor with the new bearing inside.

Machine Work

At Global Electronic Services, we pride ourselves on our dependable in-house machine work. What are some of the advantages of in-house machining?

- – Full complement of repair capabilities: A company that outsources its work generally has a modest range of repairs it can perform. It may lack the equipment, staff or knowledge to put a wider array of capabilities into use. An in-house machine shop, on the other hand, has the tools, expert staff and years of experience to solve a variety of problems.

- -Improved accountability: When companies outsource machining work, it sometimes becomes harder to pinpoint why mistakes have occurred. With centralized in-house processes, teams work closely together and must be accountable for their work to produce quality repairs.

- – Parts and materials on hand: A repair shop without in-house machining would likely have to outsource parts production and certain repairs. In-house machining generally means having the requisite parts and materials at the ready. So waiting for components or needed materials to come in won’t cause delays.

- – Reduced likelihood of errors: When a repair shop outsources motor repair work, each external vendor that touches the motor has to use different machines and different setups and tailor each one to the requirements of that repair. Working with several different setups creates multiple possibilities for the introduction of errors. With in-house machining, all work takes place on the same set of equipment and in the same place, so errors due to system changeovers are less likely.

- – Speedy turnaround: In-house machining capabilities generally mean quicker turnaround times. There’s very little waiting for parts to arrive or for third-party companies to send in their work. If a mistake or miscommunication occurs, on-site teams can coordinate to solve the problem quickly. The result is that your company will get its motor back faster and be able to start using it sooner.

- – Waste minimization: In-house machining produces less waste than sending machines out for external work. In-house processes mean that technicians can rework a bad cast, for example, rather than throwing it away.

We machine shafts, keyways, end bells and other components in our full, on-site machine shop. Our complete range of services and in-house capabilities help save our customers both time and money. Our service center equipment includes the following:

- – Lathes

- – End mills

- – Punch press

- – Vertical press

- – 30-ton bearing puller

- – Vertical cutoff saw

- – Dry abrasive blasters

- – Coil-winding machine

- – Lathe-type undercutter

- – TIG, MIG and stick welders

Dynamic Balancing

With any rotating apparatus, such as a rotor or DC armature, it is vital for it to be perfectly in balance on all sides. If there is more weight on one side of the component, it will wobble as it rotates, causing failures due to vibration and instability. These problems get exponentially worse the higher speed the motor runs. Failures that can occur due to imbalance issues in rotating groups include the following:

- – Premature bearing failure

- – Broken mounting feet

- – Destruction of driven equipment or other machine failures

- – Overheat in the motor causing winding failure

What is dynamic balancing? To understand, it’s helpful to contrast it with static balancing.

Static balance involves no rotational force. When equipment is statically balanced, its center of gravity remains on the axis of rotation. The result is that the equipment remains stable, with its axis horizontal, without requiring any application of force. Balancing, in this case, is a matter of making sure the machine remains stable and unmoving.

In dynamic balance, by contrast, the equipment — or motor — in question rotates without generating centrifugal force or requiring any force to remain in motion. Dynamic balancing uses this rotation as a tool to help identify imbalances and correct them.

For example, dynamic balancing might run a motor so that it rotates quickly. Technicians can then examine the motor and use specific electronic equipment to measure its imbalances. Armed with that information, they can then perform corrections such as adding or subtracting weights in different areas to create the correct balance and reduce vibrations. By adding or subtracting weights, they effectively change the motor’s center of mass and align it with the motor’s rotational axis.

Dynamic Balancing for an Industrial Motor

Dynamic balancing is essential for a variety of motor components, from the fan to the shaft to the rotor. Essentially, if the part rotates, it will require dynamic balancing for optimal performance and extension of the motor’s lifespan.

In an industrial motor, dynamic balance is particularly important for the rotor. The rotor is the primary moving component in a motor, it rotates in response to the torque that results from interactions between the motors windings and its magnetic field. Overheating, improper mounting and electromagnetic stresses such as vibration and electrical noise can all contribute to the imbalance of the rotor.

Dynamic balancing of an industrial motor generally requires steps such as attaching a particular weight at a specific angle, taking detailed stationary measurements, starting the motor, bringing it to operational velocity and then using the measurements to inform the addition of permanent weights for proper balance and alignment.

Here’s how we generally run balance tests at Global Electronic Services:

- – We use vibration-sensing equipment and dial calipers to detect vibration as we run the motor at full RPMs.

- – If an imbalance is detected, we remove the rotating group and correct the imbalance using one of our dynamic balancing machines.

- – We can perform balancing at NEMA or mil-spec certifications and provide a balancing report upon request.

Dyno Testing for Motors

Dynamometer testing is the best way to test a rebuilt electric motor under a full load.

A Dynamometer Tests the horsepower, torque and speed by placing a controllable load on electric motors with various horsepowers. The dynamometer can look at your power outputs in multiple scenarios and ensure your motor is running at its top available operational efficiency. We generate the maximum possible load in our testing, so you can be sure that when your motor passes, it will be up to the most challenging demands of your industry.

What Is a Dynamometer?

A dynamometer, also called a dyno, is an instrument that measures the force, torque and horsepower of your motor. Measuring the torque and rotational speed allows for the calculation of the motor’s power.

During dyno testing, as the motor runs at a full load with resistance, the dynamometer evaluates these metrics to give a realistic picture of the motor’s true operational performance.

Reasons to Dyno Test a Motor

You always want to test rebuilt motors under a full load to ensure a proper long lasting repair.

Keeping the Motor Running Under Load Capacity

Running Motors with a controlled load and testing motor functions under a wide variety of power outputs is an ideal verification that the Motor is at factory ideal functionality.

Using a dynamometer can provide essential information about a Motors performance.

Providing Performance Documentation

Dyno testing can provide a report that contains details about the test conditions, measurements of numerous metrics of motor function and charts illustrating the motor’s performance. Keeping these reports and comparing them over time allows your company to identify trends in your motor’s operation and predict when repairs may become necessary, forestalling catastrophic breakdowns. If your motor’s observed performance numbers lag significantly behind the test numbers, the motor may have a problem that requires professional attention.

Cleaning and Painting

Painting an industrial motor is not as simple as running to the hardware store and buying a can of spray paint. Special considerations must be made that are specific to the type of motor and what application it is being used for. For this reason, we carry only the highest-quality, motor-specific paints in our paint booth, such as high-temp, chemical resistant, food service or outdoor-purpose enamels. We clean and repaint every motor we rebuild, so your motor will come back looking and performing as good as new.

Cleaning

Cleaning an industrial motor during maintenance and repairs is crucial because dirt and debris can wreak havoc on a pristine motor. Dust accumulates near the bearings and interferes with their lubrication, and fluids like grease and industrial solvents work their way into the motor and gum up its precisely balanced components. Regular cleaning helps address these issues before they become more serious problems.

Painting

Certain harsh, heavy-duty industrial environments require particular types of paint. Motors used at high temperatures, around caustic chemicals, in food service applications or outdoors in extreme weather may all need the protection of robust surface treatment. The exposed motors in wind turbines, for example, or on offshore drilling operations, are particularly vulnerable to abrasive conditions.

Paint can help provide the necessary protection. Choosing paints that meet the relevant International Organization for Standardization (ISO) standards can help your company shield its motors. Industrial facilities commonly use ISO 12944, which governs the protective paint systems used to provide corrosion protection for steel.

This standard gives guidance for choosing paints for different conditions and surface treatments and indicates the level of durability to expect from different paints. It classifies different industrial environments from C1, which encompasses environments with very low corrosion potential — such as clean, heated buildings — to C5, which encompasses environments with very high corrosion potential — such as buildings with extremely high humidity or coastal and offshore marine environments with high salinity. It also recommends paint types for each.

Benefits of Painting — or Repainting — Industrial Motors

Here are a few of the benefits of using the right paints on industrial motors:

- – Weather, pollution and humidity resistance: The right paint can protect against the effects of environmental contaminants. It also helps a motor resist the impact of extreme weather and high humidity or salinity.

- – Corrosion resistance: Using the right paint can provide resistance to corrosion. It impedes the reaction of water with the motor’s metal components to keep those components functional and rust-free.

- – Reduced repair frequency: The right paint can keep your motor running smoothly and minimize the need for repairs. Its protective coating shields motor components from the elements and repels dirt to keep the motor’s performance high.

- – Extended lifespan: Using high-quality paint for your motor can help prolong its life. Its dirt, weather and corrosion protection means your motor will keep performing well year after year.

Find Out More

Comprehensive Electric Motor Rebuild Capabilities

Global Electronic Services provides thorough in-house AC and DC motor repairs and rebuilds. Trained, experienced technicians oversee and perform the work, from bearing changes and rewinding to dynamic balancing and dyno testing.

To give you the full range of AC/DC electric motor repair services you need, we also offer comprehensive testing and diagnostics. We provide complimentary testing with every AC/DC rebuild service or repair service we perform. A few of the tests included in our vast library include the following:

- – Armature test

- – Core loss test

- – DC highspot

- – Full load test

- – Megohm

- – Polarization index

- – Surge test

- – Vibration analysis

- – Winding resistance

Performing these tests tells us when an electric motor has regained its optimal functionality and achieved OEM standards, and it helps us ensure the operational longevity of your equipment. And of course, all our repairs come with an 18-month in-service warranty, so you’ll have the peace of mind of knowing any little problems have full coverage under our plan.

Complete Rebuild and Repair Services From Global Electronic Services

Global Electronic Services offers comprehensive in-house AC and DC motor shop services. We have the tools, expertise and experience to assess your motor, locate problems, perform repairs, machine components and complete accurate, reliable builds. After each repair, we also perform a thorough inspection to make sure we’ve caught all existing issues without introducing new ones.

Our extensive knowledge base and years of industry experience mean we have the professional capabilities to give you high-quality repairs. When your electric motor isn’t running as it should, trust our technicians for in-house repair and rebuild services that help reduce your downtime, improve your productivity and boost the return on your investment.

All our repair and rebuild services also come with extra protection. We offer a full warranty on our work, and we promise to beat any realistic competing bid by at least 10%. We offer rush services for high-priority jobs, and we have our trained factory technicians perform every step to ensure the highest quality.

Call us at 1-877-249-1701 or request a quote online today to learn more.

Choose Global Electronic Services for ac motor repair and more.