Axis Modules

For industrial and commercial facilities, multi-axis servos are essential components in any electronic system. These drives are optimized for outstanding performance and precision across various industrial applications, increasing overall productivity in the workplace. With many innovative features, functions and benefits, multi-axis servos have proven to be an advanced solution for any company.

-

OMRON

OMRONOmron Limit Switches D4V-8108SZ Repair Service and Sales

- Model #:

- D4V-8108SZ

- Part #:

- D4V-8108SZ

-

OMRON

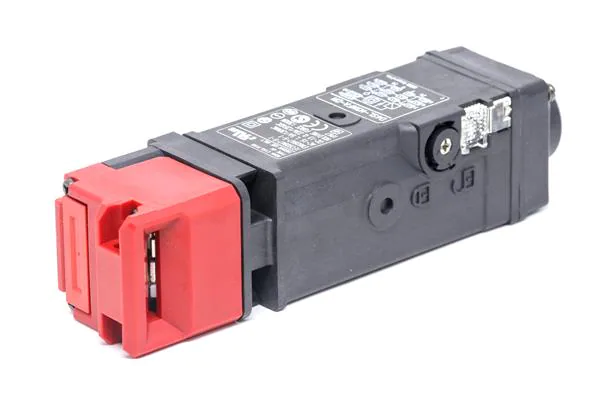

OMRONOmron Limit Switches D4SL-N3NFA-DN Repair Service and Sales

- Model #:

- D4SL-N3NFA-DN

- Part #:

- D4SL-N3NFA-DN

- New/Surplus $ 237

- Refurb. Price $166 Save up to $ 71

- Repair Price $119 Save up to $ 118

-

Allen Bradley

Allen BradleyAllen Bradley Servo Drives, Drive Accessories, Model 2094-BMP5-M | Repair Service, Sales

- Model #:

- 2094-BMP5-M

- Part #:

- 2094-BMP5-M

- New/Surplus $ 1144

- Refurb. Price $915 Save up to $ 229

- Repair Price $571 Save up to $ 573

-

Allen Bradley

Allen BradleyAllen Bradley Servo Drives, Drive Accessories, Model 2094-BMP5-S | Repair Service, Sales

- Model #:

- 2094-BMP5-S

- Part #:

- 2094-BMP5-S

- New/Surplus $ 2599

- Refurb. Price $2079 Save up to $ 520

- Repair Price $1298 Save up to $ 1301

-

Allen Bradley

Allen BradleyAllen Bradley Servo Drives, Drive Accessories, Model 2094-BM01-S | Repair Service, Sales

- Model #:

- 2094-BM01-S

- Part #:

- 2094-BM01-S

- New/Surplus $ 3035

- Refurb. Price $2428 Save up to $ 607

- Repair Price $1516 Save up to $ 1519

-

Allen Bradley

Allen BradleyAllen Bradley Servo Drives, Drive Accessories, Model 2094-BM02-S | Repair Service, Sales

- Model #:

- 2094-BM02-S

- Part #:

- 2094-BM02-S

- New/Surplus $ 3629

- Refurb. Price $2903 Save up to $ 726

- Repair Price $1813 Save up to $ 1816

What Are Multi-Axis Servos?

Multi-axis servos are modular drives designed to simplify wiring, operation, programming and diagnostic processes for faster and easier system functioning. They’re known for reducing engineering and installation times, therefore minimizing downtime on the job site.

Multi-axis drives take on a compact size with simple wiring and a modular design that provides increased flexibility. Their advanced control capabilities account for greater precision functions and heightened system performance for various demanding motion applications.

Multi-axis servos are compatible with any type of servo motor, including:

- – AC motors.

- – DC motors.

- – Torque motors.

- – Linear motors.

- – Direct drives.

- – Solenoid motors.

- – One to 50 pole pairs.

- – Two- and three-phase motors.

Uses for Multi-Axis Servos

As implied by their name, multi-axis servos are equipped to take on many multi-axis applications. The servo controllers communicate with digital servo drives through specified network commands.

Multi-axis servos are suitable for use in countless industrial and commercial industries for:

- – Robots.

- – Medical uses.

- – Computer numerical control (CNC) machining.

- – Dispensing.

- – Automated guided vehicles (AGV).

- – Semiconductor manufacturing.

- – Factory automation.

- – Industrial motor drives.

- – Factory control.

- – AC drive control modules.

What’s the Difference Between Single- and Multi-Axis Servos?

Both single- and multi-axis servo drives play a vital role in servo motor function, but these devices are not the same.

Single-axis servos are suitable for systems with one or two axes or when the power requirements are greater than 15 kilowatts (kW). In these applications, the DC power supply is internal to each drive. Single-axis servos typically feature AC to DC rectification sections, while multi-axis systems do not, making single drives more expensive.

Multi-axis servos are typically used for applications with more than three axes that require 30 kW or less of power. Each axis is powered through a single shared DC power supply, making them an energy-efficient and cost-effective option. Because modular drives only have one main AC line feed, they reduce the number of required over-current protection devices, such as chokes and filters.

Multi-axis drives can share power within a closed system, where the axes can regenerate energy for other axes in the motor. Though single-axis systems work similarly through DC bus power-sharing, multi-axis systems don’t require the use of additional fusing or wires.

Order an Axis Module Today

If your company needs multi-axis modules that can bring enhanced productivity and precision to your industrial facility, Global Electronic Services has what you need. We also provide fast and efficient repair services delivered by our factory-trained and -certified technicians.

Browse our assortment of axis modules today, or fill out an online form for more information on our products and services.