Servo Motor Hunting: Eliminating Oscillations and Instability

Precision matters in automated systems. When servo motors start to oscillate around a target position instead of holding steady, the problem is known as “hunting.” This back-and-forth movement wreaks havoc on production quality, energy consumption, and equipment lifespan.

Even small oscillations of just a few degrees can compound over time, leading to inconsistent product specifications, premature mechanical wear, and productivity losses that directly impact the bottom line. In high-precision applications like robotics, CNC machining, and packaging lines, hunting can be the difference between profitable operations and costly scrap.

The hunting phenomenon explained

Servo hunting resembles a car perpetually overshooting and undershooting while parallel parking. The motor passes its target position, reverses, overshoots again in the opposite direction, and repeats this cycle. The result? Vibration, noise, excessive wear, and imprecise positioning. But it doesn’t happen for no reason. Hunting causes typically fall into three categories:

- Improper PID tuning: When proportional, integral, and derivative parameters aren’t matched to the application.

- Mechanical issues: Excessive backlash, misaligned couplings, or improper load-to-motor inertia ratios.

- Electrical problems: Noisy signals, inadequate power supply, or encoder feedback interference.

Get an expert opinion

Having trouble getting to the heart of servo hunting? Whether it’s repair or full replacement, GES is offering 10% OFF single repairs or 15% OFF 3+ repairs on Siemens products, including servos — now through the end of March.

Spotting the problem before it escalates

While servo motors tend to run silently and smoothly, out of sight and out of mind, hunting will quickly become apparent. Here, early detection prevents costly downtime. Watch for telltale signs such as audible oscillation or whining noises, visible equipment vibration, poor finished product quality, excessive motor heat, and position errors in system logs.

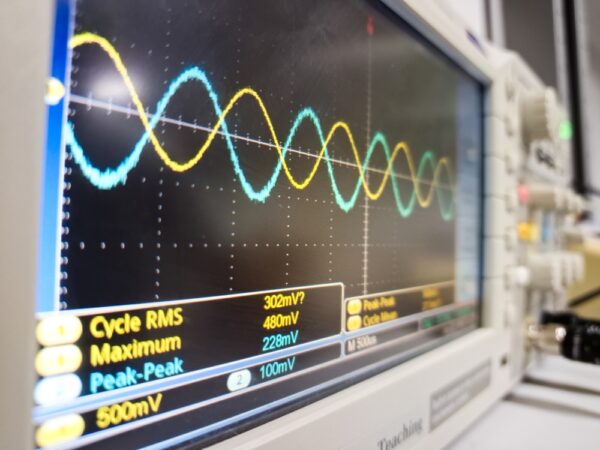

The right diagnostic tools make identification straightforward. A digital oscilloscope connected to the motor’s feedback signal typically reveals the characteristic sine-wave pattern of hunting. Many modern servo drives also include built-in monitoring capabilities that display real-time position error.

Practical fixes that work

Eliminating servo hunting doesn’t require magic — just methodical troubleshooting and targeted fixes. Most hunting problems can be resolved through one or more of the following approaches, often without expensive component replacements:

- Controller tuning: Adjust PID parameters (starting with 10-15% increments) by reducing proportional gain to decrease responsiveness, increasing derivative gain for damping, and fine-tuning integral gain to eliminate steady-state errors.

- Mechanical improvements: Address physical factors by checking gearbox backlash, verifying mounting alignment, adding shaft inertia for better load matching, and introducing mechanical damping where needed.

- Electrical optimization: Ensure clean power and signals by shielding encoder cables, separating power and signal wiring, installing line filters, and verifying proper system-wide grounding.

From oscillation to optimization

Servo hunting doesn’t resolve itself, and time spent addressing servo hunting pays dividends far beyond the immediate fix. When motors position precisely without wavering, manufacturing processes become more like orchestras than jazz improvisation — predictable, repeatable, and precisely coordinated.

Don’t settle for the jitters, jolts, or “good enough.” Whether through in-house adjustments or expert consultation, the path from oscillation to optimization is shorter than you might think. The precision you achieve today builds the foundation for tomorrow’s efficiency gains and competitive advantage.