Ice Cube Relays

Ice cube relays are essential electromechanical components that allow one circuit to control another separate circuit. They keep equipment running smoothly in various applications — either when one circuit must be controlled using a lower-power signal or when several circuits must be controlled using a uniform signal.

Explore our selection of ice cube relays below.

-

GE Controls

GE Controls420NPL0444: GE Controls RELAY 4PDT LED 24VDC

- Model #:

- 420NPL0444

- UPC #:

- 78316659683

- Part #:

- 420NPL0444

- New/Surplus $ 19

- Refurb. Price $13 Save up to $ 6

- Repair Price $10 Save up to $ 9

-

GE Controls

GE Controls420NPL044J: GE Controls RELAY 4PDT LED 120VAC

- Model #:

- 420NPL044J

- UPC #:

- 78316659680

- Part #:

- 420NPL044J

- New/Surplus $ 19

- Refurb. Price $13 Save up to $ 6

- Repair Price $10 Save up to $ 9

-

GE Controls

420NPL0224: GE Controls RELAY DPDT LED 24VDC

- Model #:

- 420NPL0224

- UPC #:

- 78316659674

- Part #:

- 420NPL0224

- New/Surplus $ 16

- Refurb. Price $11 Save up to $ 5

- Repair Price $8 Save up to $ 8

-

GE Controls

GE Controls420KPC033J: GE Controls RELAY 11 PIN 3PDT 120V

- Model #:

- 420KPC033J

- UPC #:

- 78316659608

- Part #:

- 420KPC033J

- New/Surplus $ 21

- Refurb. Price $15 Save up to $ 6

- Repair Price $11 Save up to $ 10

-

GE Controls

GE Controls420KPM022J: GE Controls NLT2AJR&FLASHING LIGHT UNIT RED

- Model #:

- 420KPM022J

- UPC #:

- 78316659581

- Part #:

- 420KPM022J

- New/Surplus $ 13

- Refurb. Price $9 Save up to $ 4

- Repair Price $7 Save up to $ 6

-

GE Controls

GE Controls420KPM033J: GE Controls RELAY 11 PIN 3PDT 120V

- Model #:

- 420KPM033J

- UPC #:

- 78316659590

- Part #:

- 420KPM033J

- New/Surplus $ 15

- Refurb. Price $11 Save up to $ 4

- Repair Price $8 Save up to $ 7

What Is an Ice Cube Relay?

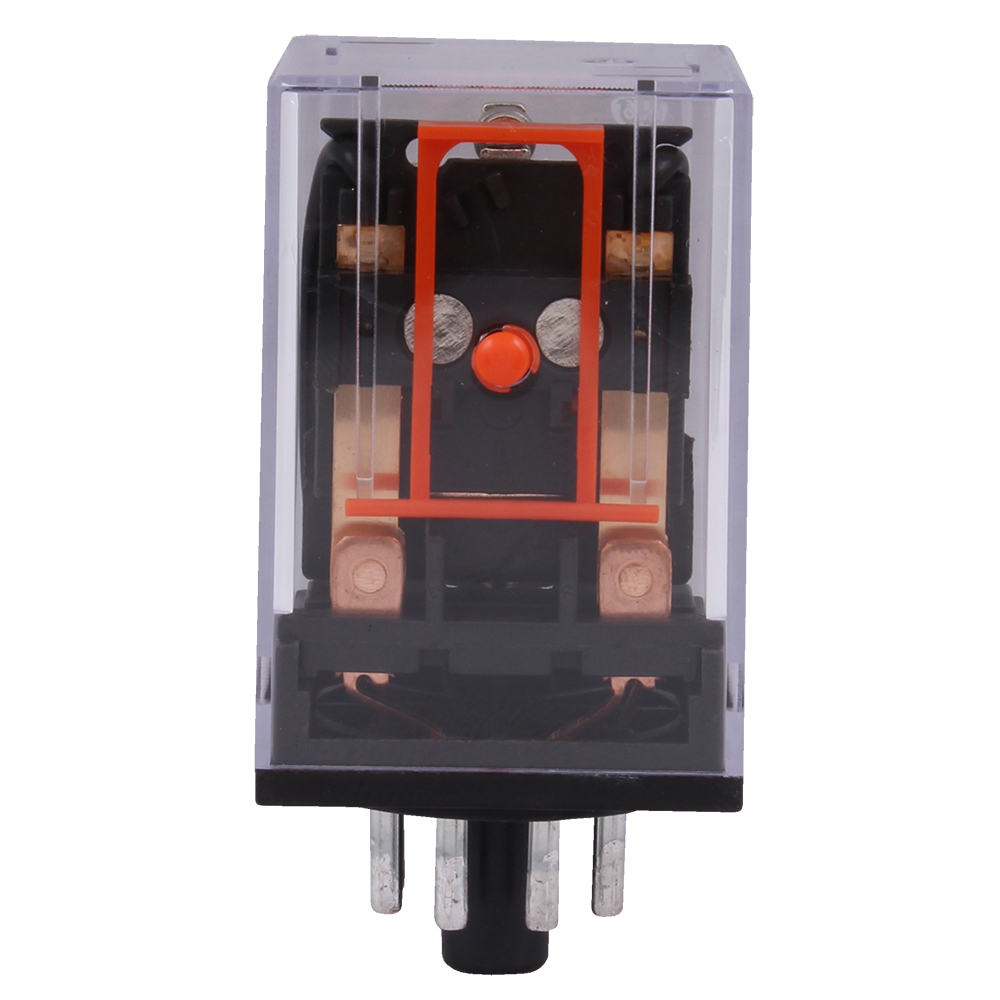

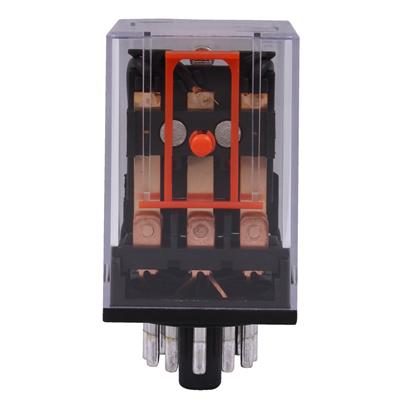

Ice cube relays are a cost-effective and widely available type of relay. Also known as plug-in relays, ice cube relays get their name from the clear plastic cover that houses the contacts and resembles an ice cube. These relays plug into sockets for use in control circuits.

Depending on the required application, a relay can act as a switch or an amplifier for the electric current between two circuits. The second, larger circuit can change between its open and closed positions to effectively control existing currents from the first circuit. Electromagnetism converts small or weak electrical inputs into stronger currents when a magnetic field activates the second circuit. This conversion either forms or breaks the existing currents, turning the device on or off as desired.

How Ice Cube Relays Work

All relays operate in essentially the same way — one circuit is used to power another. A relay consists of electrical contacts, a frame with space for pivoting mechanisms and an inductive coil to form an electromagnet. When a current is formed between a relay’s two circuits, the electrical input activates the coil and powers the end device.

The specific manner in which this occurs depends on whether the relay is normally open (NO) or normally closed (NC). Most relays are normally open, with the second circuit in the off position by default. The inductive coil pulls the pivoting mechanism in an NO relay to switch the circuit and activate an electromagnet. This process generates a magnetic field that will attract a contact to the second circuit and allow electrical currents to flow through.

The normally closed state uses the spring’s tension to hold the contacts closed by default. The NC relay keeps the second circuit in the on position until the relay produces an electromagnetic field. When the first circuit is activated, the electromagnet draws contacts away from the second circuit, pulling the connectors apart and shutting off the end device.

The contacts in ice cube relays usually have a normally open/normally closed (NO/NC) style.

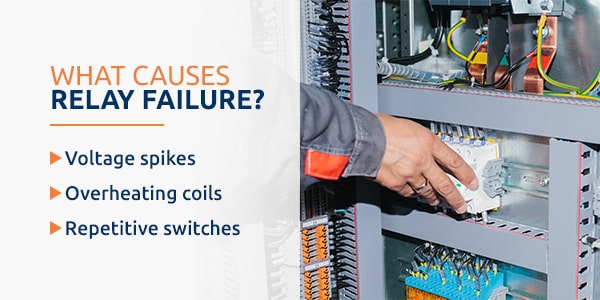

What Causes Relay Failure?

Ice cube relays with direct current (DC) coils are generally resistant to relay failures. In most instances, the damage done to relays with DC coils is caused by improper power supplies. Use a robust, corresponding DC power supply to reduce this risk of relay failure.

Alternating current (AC) coils have greater sensitivity to common power quality problems. While ice cube relays with AC coils are more sensitive, all relay types can be damaged by:

- – Voltage spikes: Each relay has a specified voltage or range of voltages it can tolerate. Exceeding this voltage will cause relay failure. Even a momentary spike may lead to a reduction in turns, lowering the resistance and its ability to generate a magnetic field. An extremely high voltage spike in either the coil or the contacts could cause instant relay failure.

- – Overheating coils: When a relay’s coils overheat, the resistive wire coating can melt and fuse different turns together inside the coil. This fusion prevents the relay from operating as intended and may lead to other electrical dangers in the control system. Excessive heat is often a result of low resistance plating corrosion, leading to a higher risk of overheating coils.

- – Repetitive switches: A disproportionate number of switching actions can cause small arcs on the contacts. Eventually, the low resistance plating will corrode and cause higher resistance. Black marks on the contact pads, excessive heat and high voltages are all signs of exacerbated corrosion from repetitive switching.

How to Test an Ice Cube Relay

First, examine the relay or check its prints to find the voltage level required to pull in the coil. The relay should also specify a range of voltages tolerated. Ensure the relay gets power, and the voltage level meets the stated requirements without exceeding the tolerated amount.

Ice cube relays may include light-emitting diode (LED) indicators, a valuable feature for proving the presence of voltage in the coil. However, the LED indicator does not indicate a functional relay. A multimeter can help identify faulty relays before they lead to failed control systems. When troubleshooting, use the multimeter to determine whether the problem is a weak connection or a lack of voltage.

Measure the voltage at particular points in the ice cube relay, including:

- – The connection point where the relay plugs in.

- – The connection point on the opposite side of the relay.

- – The connection point between the relay and the power source.

- – The connection point between the relay and the component.

Use the multimeter’s continuity function to ensure a good ground connection at each point. If there is no voltage at any of these points, check for defects in the fuse, switch or circuit breaker. If connections exist throughout the entire relay and the voltage is correct, the faulty relay may need a total replacement.

Some ice cube relays include test buttons to allow manual actuation of the contacts. When voltage is not applied to the coil, manual actuation can be a helpful feature for troubleshooting circuits. When the test button is pushed, the contacts operate. They return to their former state when the test button is released.

Benefits of Ice Cube Relays

Relays perform various tasks in industrial control applications, such as switching, amplifying, separating or multiplying a circuit’s existing electrical input. Benefits of ice cube relays include:

- – Cost-effectiveness

- – Simple and effective operation

- – AC or DC contact switching

- – Voltage conversion

- – Compact size

- – Long life span

- – High resistance

- – Quick installation

- – Minimal maintenance

Order Ice Cube Relays Online Today

Relays are a crucial device used to keep equipment and systems running smoothly. Global Electronic Services offers a wide selection of relays, including ice cube relays suited for various applications. Browse our products and request a quote today. Our team of experts can help your company find the best solution for the job.