Made In Space: Manufacturing Update

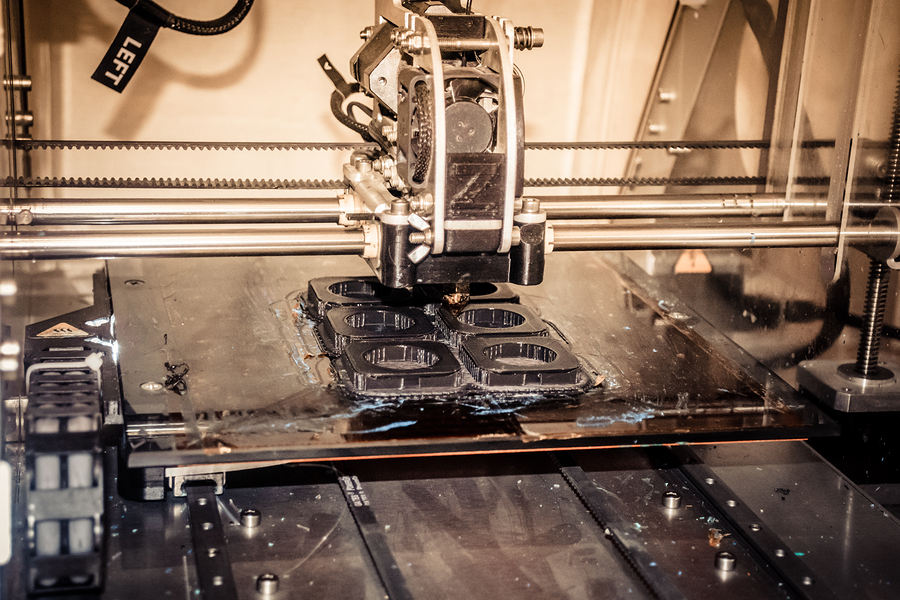

In August, we wrote a piece about advances in space manufacturing. Because of its sustainability and cost-effectiveness, 3-D printing will likely play a major role in developing the space manufacturing industry. And, with the ability to build and repair satellites in space, NASA experts, government agency officials, and commercial company leaders may no longer have to worry about the expenses and complexity of building structures on land and transporting them into orbit. In fact, 3-D printing allows astronauts to transport much smaller amounts of materials into space where construction can take place in highly automated processes. This kind of development means larger space stations and telescopes as well as opportunities for those in commercial companies to manufacture in space.

New manufacturing innovations

Made In Space 3-D Printer

California-based Made In Space launched a new 3-D printer on a path toward the International Space Station (ISS) Dec. 12. This 3-D printer is designed to produce an optical fiber called ZBLAN. Producing ZBLAN within Earth’s gravitational pull causes microscopic flaws in the fiber’s crystals. Producing it in a zero-gravity environment, however, will allow Made In Space to produce the highest quality fiber to be used in telecommunications, the internet, and further developments in space. Made In Space insiders intend to produce 330 feet of fiber optic cable on this initial launch to be tested upon its return. With desired results, Made In Space will put ZBLAN into production, making it the first space-made industrial product.

Also in December, NASA decision-makers selected three companies to build prototypes for large space-based 3-D printers for space manufacturing, investing $10.2 million in the project called FabLab. One of the companies NASA enlisted is Tethers Unlimited. Tethers Unlimited is working on several projects to bolster the growth of the upcoming space manufacturing industry. Such projects include the Refabricator, which will reuse and recycle materials on the ISS. Other projects include the Trusselater, which will create large carbon composite structures, and the OrbWeaver, which launches with a ring that it later breaks down and recycles into satellite antenna. It is clear NASA leaders are including sustainability in their long-term space travel plans.

Space manufacturing future

So, are we getting closer to a large-scale space manufacturing industry in the near future? NASA experts, government agency officials, and commercial company leaders are investing in the possibility with NASA funding Made In Space and Tethers Unlimited to develop essential parts in building up the industry. With funding, these companies do not need the outside support of capital investors, so they can focus on innovation.

Besides this initial investment, the space manufacturing industry may also prove to be a self-sustaining system. Made In Space partnered with Braskem to develop an extruder with the ability to reuse and recycle waste plastic for 3-D printing new structures. Such a tool could create a closed-loop manufacturing cycle and improve production both in space and on Earth. In the more immediate future, the ability to 3-D print in space may appeal to commercial satellite builders who are currently reaching physical capacities when launching their satellites. With more and more demand for bandwidth, building in space appears to make more sense as far as costs and efficiency are concerned.

Those who are investing in new space technologies are creating an environment for the space manufacturing industry to evolve. Space tech company leaders continue to improve their machines and products with the goal of top efficiency in this field, promising optimal growth and sustainability for the future of space manufacturing.

Even with its growth, however, barriers still stand in the way of the space manufacturing industry’s development. Companies like Made In Space and Tethers Unlimited do not have support from the private sector. Right now, that is not holding them back but, eventually, the demand for new technology may shift into the commercial realm. For long-term resilience, company leaders need viable reasons to invest in space technologies, move manufacturing into space, and remain there.