Made in Space: Additive Manufacturing Advances

While additive manufacturing in space isn’t anything new — astronauts aboard the International Space Station (ISS) have been 3-D printing tools and other objects since 2014 — it’s seen a major change. The most recent advancement didn’t actually happen in space but, rather, in a “space-like environment,” and it brings zero-gravity structure printing one step closer to reality.

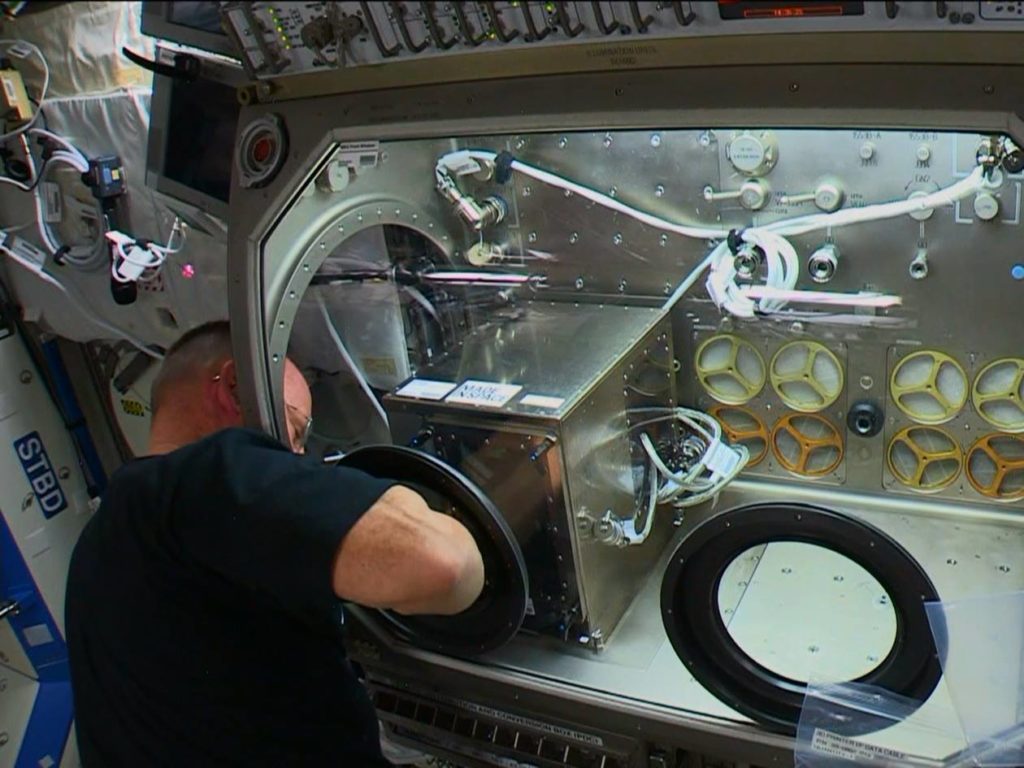

Made In Space

California-based company Made In Space, the same one that built the ISS’s printers, tested additive manufacturing in zero gravity over 24 days. The project included producing a nearly three-foot beam. And while the ISS printers don’t operate in the vacuum of space, the Made In Space team is pushing toward that possibility. Through the test period, they made additional polymer-alloy objects in the thermal vacuum chamber, an environment mimicking the lack of gravity as well as the vacuum of space and space temperatures.

Astronaut Barry Wilmore shows off a ratchet wrench made with a 3-D printer on the International Space Station. Source: NASA

Archinaut

Source: NASA

Part of a larger project, Archinaut, the zero-gravity printer that produced the beam and other structures will be used as part of a new robotic system. In fact, the Archinaut project is said to include a satellite with robotic arms that will assemble the printed pieces in space, allowing for spacecraft development. Having the ability to build spacecraft in space, rather than on Earth where we’d still have to launch them, would make these craft much more advanced than anything currently available. This could become a reality as early as the 2020s. And it wouldn’t solely focus on building new spacecraft: Archinaut could also repair existing satellites by repairing and replacing parts using 3-D printing.

Telescopes

These technology advancements also mean astronauts may soon be able to build larger space telescopes, allowing NASA scientists to search for life outside Earth. These telescopes, of course, would be built in space using materials sent to the Archinaut spacecraft for production. Why the need for space-built scopes? At this point, technology is not yet advanced enough to fit a telescope large enough to produce high-quality imagery into a launch vehicle to get it from Earth to space.

With these projects and more potentially on the way, space manufacturing could be a boon to the industry. In fact, analysts expect it to reach $4.7 billion over the next 10 years. And it’s not just manufacturers themselves who could benefit: Materials producers, hardware and software companies, as well as additive manufacturing businesses will likely see opportunities.

With these projects and more potentially on the way, space manufacturing could be a boon to the industry. In fact, analysts expect it to reach $4.7 billion over the next 10 years. And it’s not just manufacturers themselves who could benefit: Materials producers, hardware and software companies, as well as additive manufacturing businesses will likely see opportunities.

Should terrestrial manufacturers begin looking to the stars for the next steps of their careers? Probably not — unless they’re moonlighting as NASA astronauts or personal friends of Elon Musk or Jeff Bezos. However, they may begin seeing “Made in Space” on consumer and industrial products in the next decade. On the other hand, they probably won’t need to worry about losing their jobs to space robots as these space products are likely to be those too expensive or tough to produce on Earth.