The Common Causes of PCB Failure

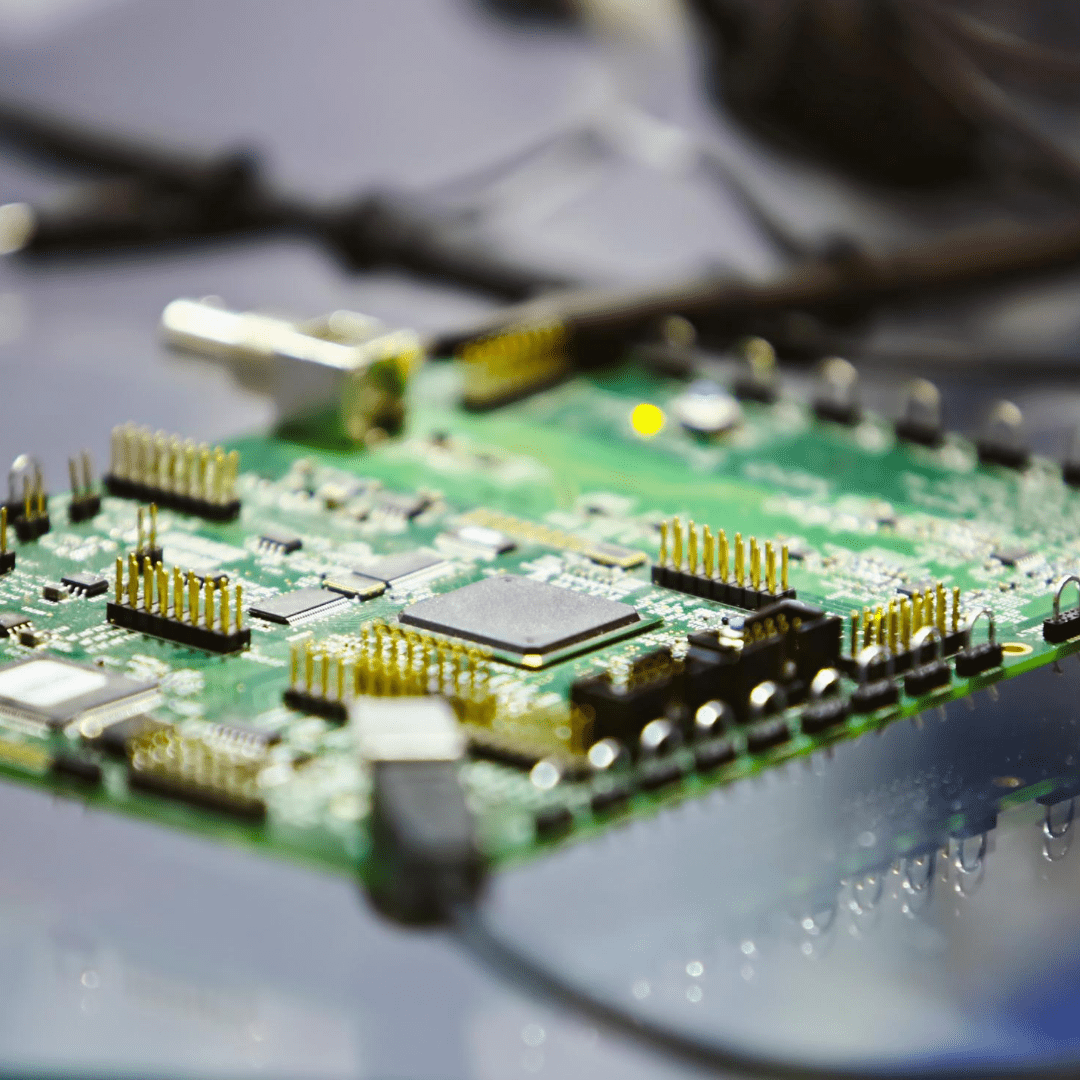

Printed circuit boards (PCB) are arguably the most important part of any piece of electronic equipment — and used in virtually all but the simplest devices. These boards provide the layout you need for creating electrical and mechanical connections between individual electronic components. If a PCB malfunctions, it can cause your equipment to go down until you find and repair the source of your issue.

The Most Common Causes of PCB Failure

A PCB can fault out for multiple reasons. Some will be out of your control, but others are preventable if you know what to look for. If you are putting a printed circuit board together or have manufacturing and distribution equipment that relies on these devices to run, it pays to know the typical PCB defect list so you can try to determine the source of an error and the degree of repair required.

The Component Design

Poorly designed PCBs can cause serious overheating issues and complete power failures. PCBs should always have enough space to support all of their components. The nature of the components’ installation is also important — if the technician building the board used substandard soldering techniques, you could wind up with loose parts, bad connections, leakage, corrosion and burnt areas.

The Quality of the Components

Any piece of electronic equipment will only perform as well as the components used to create it. If your PCB was manufactured using substandard components, or the board itself is of insufficient quality, you could eventually see visible surface defects such as leftover flux and loose soldering connections. Other symptoms of poorly manufactured PCB components include connection issues and pieces bending or breaking under stress.

Different Environmental Factors

The environment can wreak havoc on printed circuit boards. Environmental factors that can lead to PCB failure include:

- Dust: Dust and other debris can interfere with connections or cause your electronic component to overheat.

- Temperature: Extreme changes can cause the PCB to expand and contract, damaging and warping connections.

- Moisture: Water and humidity are detrimental to electronics and can cause PCB rusting, corrosion and oxidation.

Component Age and Wear

All electronic devices have a useful lifespan. When your PCB components come to the end of theirs, you will experience power issues. In many cases, aging printed circuit board components will begin showing their age by displaying intermittent symptoms. When they finally give out, you can expect a complete power failure of the board until you replace the part or pay the cost of a new board.

How to Avoid PCB Failure

If you rely on PCBs to power the machines that keep your company running, failure can lead to mounting costs. The good news is that you can take steps to avoid PCB failure by partnering with a professional electronic service and maintenance provider for repair work and proactive care.

Professional electronic service and maintenance providers can test and inspect your PCB for component condition, calibration and performance. If they discover faulty components, poor workmanship or other issues on the PCB defect list, they will make the necessary repairs and adjustments to ensure optimal condition.

Let Us Test Your PCB

At Global Electronic Services, we provide all the services you need to keep your company’s PCBs and other electronic equipment in peak condition and help you avoid unexpected downtime. Get in touch with us today to request a quote and to learn more about our free evaluations, fast turnaround times and pricing guarantee.