Why Electrolytic Capacitors Fail (and How to Replace Them)

A capacitor shouldn’t hiss, bulge, or leak — when it does, you’ve got trouble. Electrolytic capacitors are known for their compact energy storage and filtering capabilities, but they’re also known to fail (spectacularly, in some cases). Whether it’s a slow loss of capacitance or a sudden pop and puff of smoke, the damage can bring an entire circuit to a halt. Knowing why these components fail (and how to replace them) can help protect other expensive parts from collateral damage.

Heat builds up, and failure follows

Excess heat is the biggest threat to an electrolytic capacitor. Heat causes the electrolyte inside to evaporate, degrade, or chemically break down. Over time, this alters the component’s capacitance, internal resistance, and performance stability. A failing cap often leaves behind some common telltale signs:

- A domed top or bulging sides.

- Leaking electrolyte around the base.

- Faded or discolored labels from prolonged heat exposure.

- Higher-than-normal ESR (equivalent series resistance) in test readings.

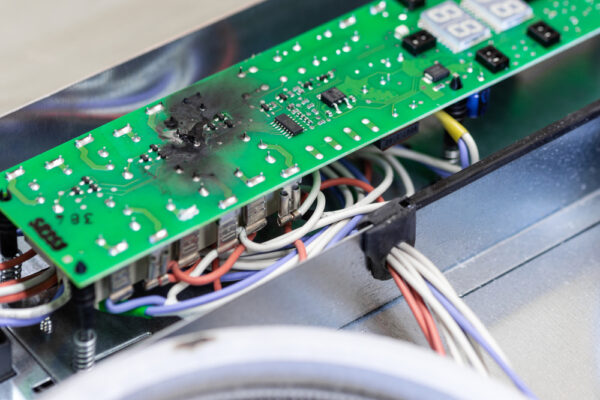

Sometimes, the capacitor doesn’t just degrade: it fails catastrophically. Heat and pressure build inside the casing until the safety vent pops, ejecting vapor or material. That kind of failure can damage surrounding components or leave residue on the board.

Ripple current creates internal stress

Ripple current may sound harmless, but it generates real heat inside a capacitor. When the alternating component of DC current passes through the cap, it’s dissipated as heat. This thermal stress increases as frequency and current rise — especially in power supply applications. Signs ripple current may be causing damage include:

- Elevated temperatures near switching power supplies.

- Burn marks on the PCB beneath the cap.

- Noise or instability in power delivery systems.

- A shortened expected service life, especially under heavy load.

To avoid this, manufacturers often choose capacitors with ripple current ratings higher than the application requires. But if that margin gets miscalculated — or if the operating environment changes — failure is only a matter of time.

Voltage surges break down insulation

Electrolytic capacitors have a thin dielectric oxide layer, and overvoltage can punch right through it. Whether from a lightning strike, switching transient, or unstable supply, voltage that exceeds spec causes internal arcing and short-circuiting. When this happens:

- The cap may heat up and fail suddenly.

- A shorted capacitor can pull too much current, damaging other components.

- Circuit protection elements, like fuses or breakers, may trip or blow.

Electrolytic capacitors don’t recover from this kind of damage. Once the dielectric breaks down, the component needs to be replaced — no second chances.

Keep in mind that even in perfect conditions, electrolytic capacitors degrade over time. The internal electrolyte slowly evaporates through the seal, and the dielectric weakens. Lifespan depends on temperature, voltage, ripple, and physical design. Some systems are still running with 10-, 15-, or even 20-year-old capacitors!

How to replace an electrolytic capacitor safely

Swapping a failed capacitor isn’t just plug-and-play. You’ll need to match the original spec — or better. That includes voltage rating, capacitance, ripple current tolerance, and physical dimensions. And yes, polarity matters — electrolytics are polarized. Follow these simple steps to handle a replacement:

- Discharge the capacitor first. Even a “dead” cap can store dangerous voltage.

- Match voltage and capacitance but favor a higher voltage rating if space allows.

- Watch the temperature rating — 105°C caps perform better in hot enclosures.

- Clean the area thoroughly before soldering the replacement in place.

One last tip

If one capacitor failed, others of the same age might not be far behind. Right now, GES is offering 10% OFF single repairs or 15% OFF 3+ repairs on ABB products. If you’ve got capacitor issues, we’ll handle them!

A bad cap can signal deeper problems

A failed capacitor could be the symptom — not the cause. Power supply instability, excess heat, or incorrect ripple filtering may continue to kill replacements. Expert diagnostics can trace the root problem and recommend lasting solutions. GES will help you get to the bottom of capacitor issues, so you can get back to the level of reliability your factory demands.