What Causes IGBT Failures in AC Drives?

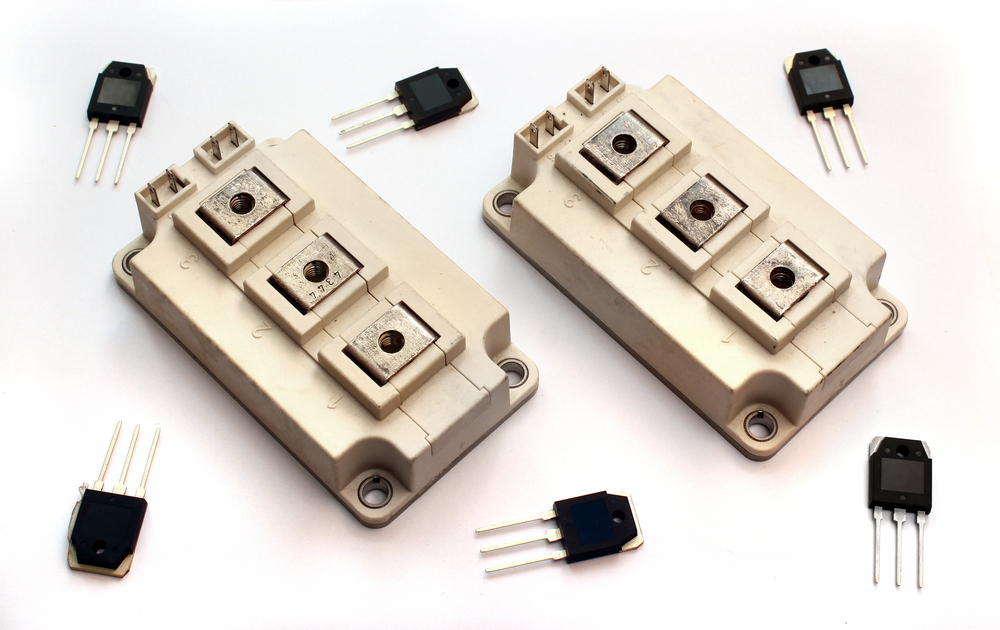

Insulated-gate bipolar transistors (IGBTs) are responsible for power conversion and motor control within AC drives. Namely, these semiconductor devices are prized for their efficiency and fast switching capabilities. However, IGBTs are highly sensitive, which can make them prone to failures if they’re not well-maintained or serviced accordingly.

Let’s take a look at how to properly protect and service these components — and, in doing so, sustain the reliability and longevity of AC drive systems.

Common causes of IGBT failures

The factory floor is home to no shortage of catalysts that can disrupt or damage IGBTs. And several variables can arise over the course of normal operation that threaten the integrity of these components:

- Thermal stress: IGBTs generate heat during operation, and excessive temperatures can lead to degradation of the semiconductor material — and eventual failure. Inadequate cooling or prolonged operation under high-load conditions can exacerbate this issue.

- Voltage spikes and overvoltage: These can occur due to power supply fluctuations, lightning strikes, or switching transients within the drive system. Even brief exposure to voltages exceeding the IGBT’s ratings can result in catastrophic failure.

- Short circuits: Short circuits, whether caused by insulation breakdown, wiring faults, or external factors, can subject IGBTs to extreme currents. While modern IGBTs have some short-circuit withstand capability, prolonged exposure can lead to drive failure.

- Mechanical stress: Vibration, shock, and stress due to improper mounting are all concerns. These stresses can cause internal damage to the device structure or lead to fatigue failure of solder joints and wire bonds.

- Improper gate drive: The gate drive circuit controls the switching of the IGBT. Improper gate voltage levels, inadequate current supply, or oscillations in the gate drive signal can lead to inefficient switching, increased power dissipation, and eventual failure.

Protecting IGBT functionality

Against the constant threat of stressors (both environmental and electromechanical), maintenance techs need to focus on controllable variables to preserve IGBT function. A proactive approach should involve all the following:

- Proper thermal management: Implement well-designed heat sinks with appropriate thermal interface materials and ensure adequate airflow or liquid cooling systems are in place.

- Voltage protection: Install snubber circuits to suppress voltage spikes and implement overvoltage protection devices such as metal oxide varistors (MOVs) or transient voltage suppressors (TVS). Proper grounding and shielding of the drive system are also essential to mitigate voltage-related issues.

- Short-circuit protection: Protect IGBTs from short-circuit events by incorporating fast-acting fuses in the power circuit and implementing electronic short-circuit detection and protection circuits. Using IGBTs with enhanced short-circuit withstand capabilities can provide an additional layer of protection.

- Mechanical considerations: Mitigate mechanical stress through proper mounting techniques that ensure even pressure distribution and use vibration isolation mounts in high-vibration environments. Regular inspection of mounting hardware and re-torquing as needed can prevent failures caused by mechanical fatigue or loosening over time.

- Optimized gate drive design: Enhance IGBT performance and reliability with careful selection of gate resistance to balance switching speed and voltage overshoot, along with optimization of gate voltage levels for turn-on and turn-off. Soft-switching or resonant gate drivers can further improve IGBT longevity and efficiency.

Engineering resilience to prevent IGBT failure

It takes a holistic approach to prevent IGBT failures, but it’s worth it to protect the operational integrity of the AC drives they power. Safeguarding against environmental and electromechanical threats is the first (and best) step in protecting against the many problems (and costs) that follow AC drive performance issues.

Having trouble with your AC drives?

This October, GES is offering 10% off any drive repair — or 15% off three or more drive repairs! Whether it’s an IGBT issue or something else, don’t let AC drive performance issues impact your critical production processes.