What Are the Pros and Cons of Additive Manufacturing?

Additive manufacturing, also known as 3D printing, creates products by layering materials. Unlike traditional manufacturing, these processes add materials to create objects rather than subtracting materials or using shaping or molding processes. Additive manufacturing is often used to make small quantities or prototypes.

Manufacturers choose to use additive manufacturing instead of other processes for many reasons. Learn more about the advantages and disadvantages of additive manufacturing and how your company can benefit.

Pros of Additive Manufacturing

Here are some of the main benefits of additive manufacturing:

1. Rapid Prototyping

Additive manufacturing can produce prototypes quickly. With some traditional processes, creating a prototype can take weeks or even months. Additive manufacturing allows you to create prototypes in just a few days. You can print multiple prototypes and make adjustments quickly before committing to a production run. Modifications using traditional manufacturing processes are often more costly in comparison.

2. Improved Accuracy

Additive manufacturing can be more accurate than traditional processes. It doesn’t require human intervention, leaving less room for error. These processes also offer more flexibility and customization. You can adjust designs digitally before printing and customize products to meet your clients’ specific needs or applications.

3. Waste Reduction and Energy Savings

Additive manufacturing generates little waste, creating products by adding layers of material as needed. Any excess filament or powder used to create the product can also be recycled. Additionally, additive manufacturing machines are smaller, use less energy and don’t need secondary tools, such as cooling systems. The energy savings can be significant enough to offset the cost of purchasing equipment in just a few years.

4. Inventory Reduction

Additive manufacturing helps reduce inventory costs by creating products on demand. Your business can make products as needed without purchasing or storing too much inventory. Reducing your stored inventory while still meeting consumer demand can help your business save and reduce risks.

5. Environmentally Friendly

Additive manufacturing is better for the environment. Traditional manufacturing processes often produce a significant amount of carbon dioxide, contributing to pollution affecting the environment and public health. Additive manufacturing creates less waste and saves energy compared to traditional processes, making this method advantageous for manufacturers that want to improve their sustainable practices.

6. Unique and Customizable Design

Additive manufacturing allows unique designs that are difficult or impossible with traditional manufacturing processes. You can achieve more complex shapes and designs to meet customer demands and specifications. Additive manufacturing allows you to create customized products more efficiently and make parts that may be too complicated or expensive to manufacture with traditional processes.

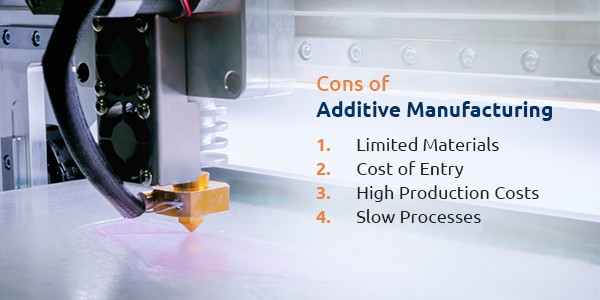

Cons of Additive Manufacturing

While additive manufacturing has many benefits, there are also some drawbacks. The main cons of additive manufacturing include the following:

1. Limited Materials

If you choose additive manufacturing, you’re typically limited to specific materials that work with the equipment, so sometimes this process isn’t the best option. With prototyping, you often won’t encounter problems with materials since the parts are for early testing and review. However, you must ensure parts for final assembly consist of materials that suit their applications.

2. Cost of Entry

The initial setup for additive manufacturing can be more expensive than traditional processes. Investing in the right equipment and training for staff can be a disadvantage for new or small businesses that want to start using these processes. Including additive manufacturing can be expensive for businesses already using traditional methods.

3. High Production Costs

While production costs have decreased as technology has become more common, accessing specialized materials can be expensive for some companies. Slow processes can also add to production costs.

4. Slow Processes

Additive manufacturing can have slow build rates and doesn’t scale well to allow businesses to create a high volume of parts. Depending on the product, additive manufacturing can take hours, whereas traditional manufacturing takes seconds. If you need to create many products quickly, additive manufacturing can be too slow unless you work with a 3D printing specialist.

Contact Global Electronic Services for Equipment Service and Repair

If you want to include additive manufacturing in your services, you need specific equipment. Once you invest in the proper equipment, you’ll need to keep the machinery in good condition to get the best return on your investment, and Global Electronic Services can help.

Our repair services can keep your equipment in good condition. We use the latest technology to test your equipment’s operational capabilities and replace any necessary components. Our repair process is quick, and we offer rush service if needed. Request a quote today, or contact us to learn how we can help you with your equipment.

Our repair services can keep your equipment in good condition. We use the latest technology to test your equipment’s operational capabilities and replace any necessary components. Our repair process is quick, and we offer rush service if needed. Request a quote today, or contact us to learn how we can help you with your equipment.