UV Light Solutions for Industrial Disinfection

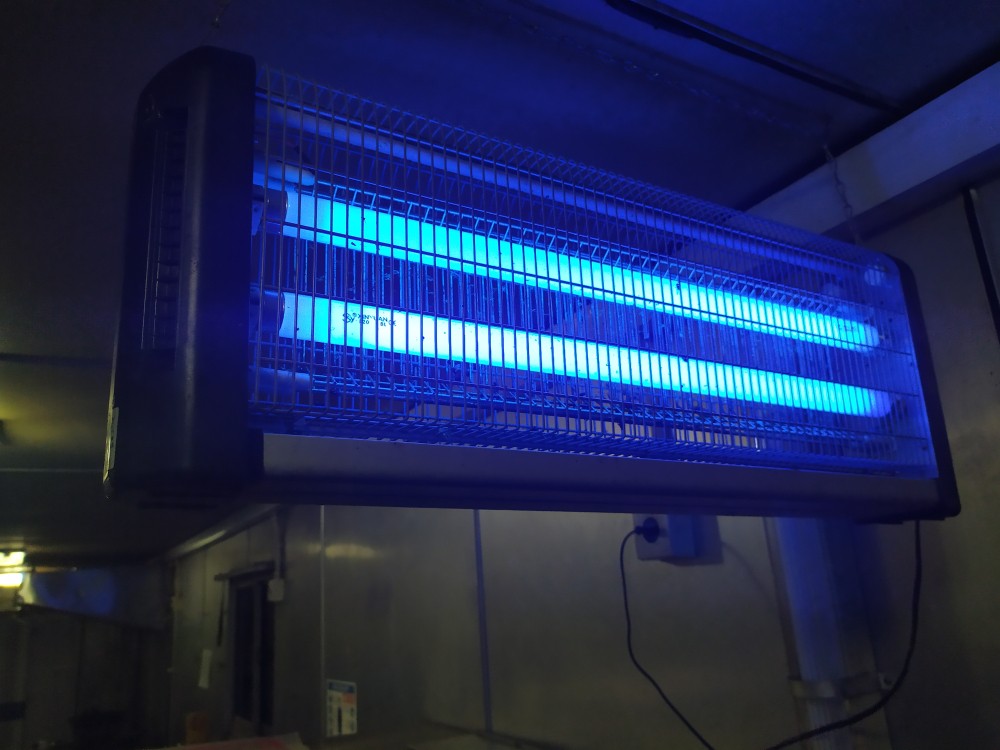

From Class 8 clean rooms to sterile handling stations, manufacturing facilities can have significant disinfection demands. Industrial HEPA filtration systems and ozone sanitization have long served the production requirements for cleanliness, manufacturers are increasingly investing in UV light solutions as an alternative approach to disinfection.

UV light has become a pivotal technology during the pandemic because of its efficacy in eliminating airborne pathogens. UV disinfection is a proven solution for eradicating airborne and surface traces of the virus that causes COVID-19, and it’s also showing value for sterilizing sensitive environments of virtually any microbial presence.

What is UV light disinfection?

Ultraviolet (UV) light is a type of electromagnetic radiation effective for eradicating bacteria, mold spores, viruses, and germs of all kinds. Unlike visible light, UV light is imperceptible to the naked eye and produces shorter wavelengths. For at least 40 years, companies have employed UV light to destroy bacteria and other germs. It’s increasing popularity is due to its ability to prevent the replication and spread of microscopic organisms, including bacteria and viruses, by breaking down their RNA and DNA.

The benefits of UV light disinfection

Traditional disinfection methods, such as cleaning with bleach, ammonia, or other chemicals, don’t eliminate all germs, and cleaning by hand is tedious, time-consuming, and with chemical exposure, potentially harmful. Manufacturing facilities are embracing UV light disinfection. The benefits of a UV approach include:

- Efficacy. UV light destroys a wide range of viruses, germs, and other harmful microorganisms other cleaning methods miss.

- A non-toxic approach. Since it doesn’t require harmful chemicals, UV light disinfection is easier on the environment, and your employees, than traditional disinfection methods.

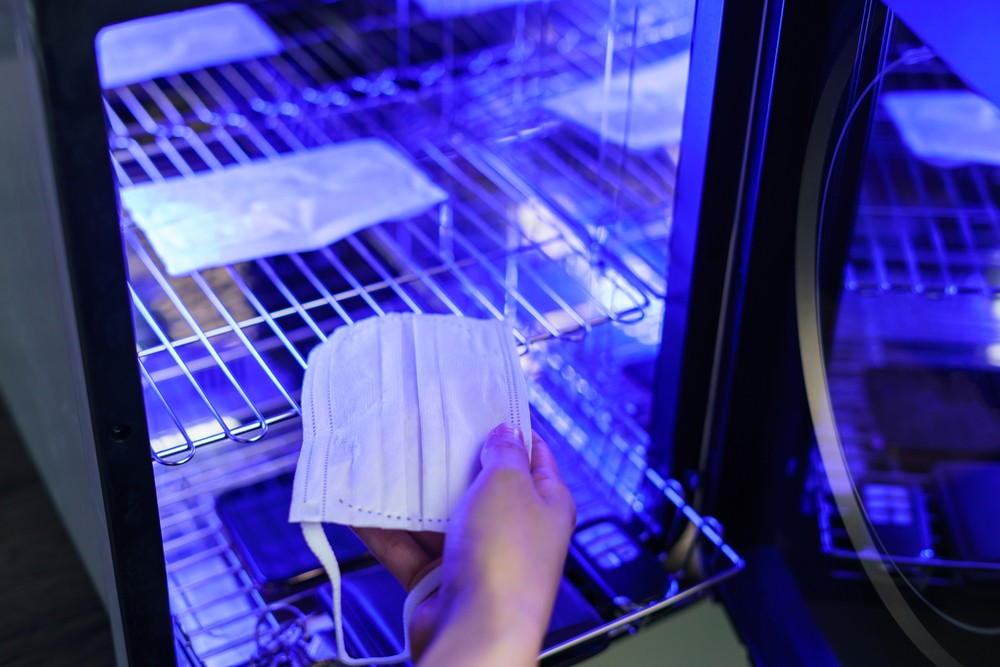

- Elimination of airborne and surface germs. Certain UV light disinfection devices can eliminate germs from almost anywhere.

- Affordability. UV light disinfection methods typically require a one-time investment and reduce the need to restock traditional cleaning products.

There are some dangers associated with exposure to UV light, but simple safety precautions, such as wearing protective eye gear and covering exposed skin, can effectively prevent injury.

COVID-19 disinfection opportunities

CU Boulder recently found that UV light is an effective method of eliminating COVID-19 from public places. In fact, CU Boulder professor of environmental engineering and senior author, Karl Linden said, “Of almost every pathogen we have ever studied, this virus is one of the easiest, by far, to kill with UV light.”

With the recent influx of Omicron variant cases, implementing effective disinfection methods is a priority. Manufacturers should consider the potential of UV light disinfection as a long-term solution for their factory settings.

Demand for UV disinfection is rising

As manufacturers consider the implications of COVID-19 as a lingering disruptor, UV light becomes more pivotal in planning for facility disinfection. According to Allied Market Research, the market for UV disinfection equipment was valued at a paltry $1.3 billion in 2019, but it is expected to reach a value of $5.7 billion by 2027, a CAGR of 17.1%.

This significant increase in demand isn’t coincidental: It’s representative of a persisting need for better sterilization in facilities threatened by COVID-19 and other invasive microbes.