Ways to Upcycle Unneeded Manufacturing Hardware

When your company’s old computers, vehicles or other machines die after years of good use, you might be tempted to toss them in the trash. Most items no longer useful to us end up in a landfill somewhere, and manufacturing hardware is no different. But were you aware of the detrimental effects wasting these parts can have on the environment?

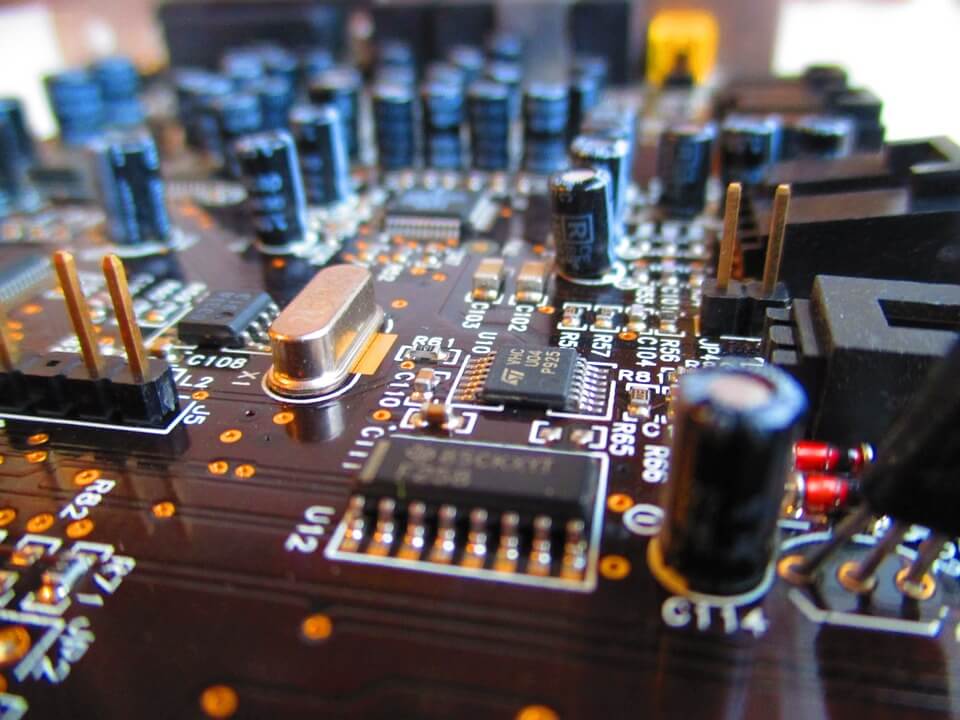

Global Electronic Services repairs all types of industrial electronics, but we also know these electronics can have negative effects on nature. From poisonous materials entering our water to dangerous toxins spreading through the atmosphere and affecting humans and wildlife, there are multiple ways our devices can harm the Earth. However, your business can be part of the solution by upcycling unneeded manufacturing hardware. Here are four ways to do it.

1. Upcycle Your Salvageable Parts for a Newer Model

Repurposing old hardware has become a trend in recent years, inspiring creativity in many who feel passionate about reusing items. One of the simplest ways to upcycle is by taking parts from old manufactured items and applying them to your company’s new ones. For example, you may have an old computer that has outlived its use, but chances are some of the parts inside it still work. You might even be able to use those parts to fix a newer machine.

2. Repurpose Hardware With Your 3D Printer

There are nearly endless possibilities for new items you could create out of old hardware. Thanks to 3D printing, this process can be even easier. Digital platforms online offer many designs and models you can use to upcycle manufacturing hardware with a 3D printer. This is a simple and efficient way to make something useful out of your old electronic parts.

3. Donate to an Upcycling Service

If your company wants to declutter while staying environmentally friendly, you can donate all your hardware to an upcycling service. Thanks to this rising trend, it’s easy to go online and find services that take old items and turn them into other practical materials. By donating, your company can both help protect the environment and give your items away for someone who may need them more than you do.

4. Check Out Online Manufacturing Trends and Ideas

Just when you think you’ve run out of ways to upcycle your manufacturing hardware, the internet is there to prove you wrong. If you look for creative and useful ideas to upcycle, you can find CD-ROM drives turned into music players, car parts turned into lamps and computer parts turned into clocks.

The next time your company has outdated or broken electronics to throw out, consider these four ways that they could be used to benefit you or others. Even if a piece of equipment doesn’t work the way it should anymore, that may mean it still has uses you never considered or expected. Upcycling your unneeded items does a service for the planet and the creative world.

Do you have another idea on how to upcycle your manufacturing parts? Comment on the post below to share it with us! Then, contact us to request a quote for your repair job or to learn more about what you can do with your used electronics.