Troubleshooting Signal Noise in Sensor and PLC Connections

A temperature sensor on an injection molding line jumps erratically between 180°F and 195°F, triggering constant alarms and forcing manual operation. The actual temperature stays steady at 188°F, but electrical noise corrupts the signal before reaching the PLC. Signal noise undermines automation systems by feeding unreliable data to control algorithms that depend on accurate inputs. It’s a problem that’s all too common — and all too frustrating for equipment operators.

This troubleshooting guide provides a systematic approach to identifying noise sources and implementing targeted solutions that restore clean signal transmission.

Step 1: Identify the noise pattern

Start by characterizing when and how the noise appears. The pattern reveals different root causes that require different solutions.

Decision point: Is the noise constant, intermittent, or event-triggered?

- Constant noise appears as a steady fluctuation in readings, typically indicating power supply ripples, poor grounding, or damaged shielding. Check power supply voltages with an oscilloscope and measure ground potential differences between sensor locations and PLC inputs.

- Intermittent noise shows up sporadically, suggesting loose connections, corroded terminals, or moisture infiltration. Wiggle test cables and connections while monitoring signal quality. Check junction boxes for water ingress or corrosion.

- Event-triggered noise correlates with specific equipment operations like motor starts or welders firing, pointing to electromagnetic interference from nearby equipment. Use an EMI probe to identify interference frequencies during operation cycles.

Step 2: Isolate the source location

Once you understand the noise pattern, determine whether the problem affects individual components or entire system sections.

Decision point: Does the problem affect single sensors, multiple sensors, or entire zones?

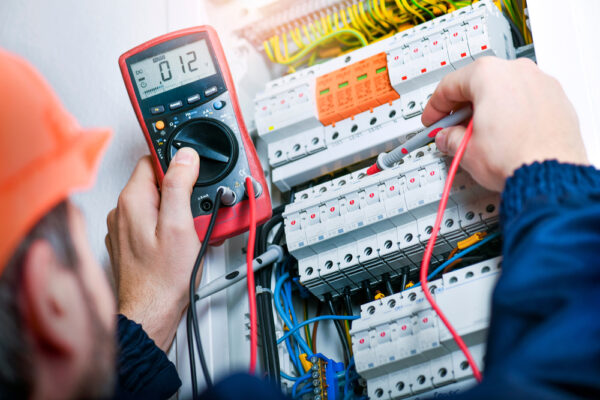

- Single sensor issues typically involve local wiring problems or sensor damage. Test the sensor with a known good cable and verify proper termination resistance for 4-20mA loops. Check the sensor power supply voltage at the device.

- Multiple sensor problems on shared signal paths suggest common mode interference or power distribution issues. Measure the common mode voltage between signal commons and facility ground. Check for shared neutral conductors creating ground loops.

- Entire zone failures indicate facility-wide interference or power quality issues. Monitor power quality during production cycles to identify voltage sags, harmonics, or transients. Map electrical distribution to identify shared transformers affecting multiple sensor circuits.

Step 3: Apply targeted solutions

Match your solution to the specific noise source and affected equipment scope.

- For constant noise from power supply issues: Install line reactors or isolation transformers. Add ferrite cores to sensor power cables near PLC inputs. Replace switching power supplies with linear types for noise-sensitive analog inputs.

- For intermittent connection problems: Improve termination using proper torque specifications and terminal compounds. Replace corroded connectors with sealed versions. Add strain reliefs to prevent cable movement.

- For EMI interference: Separate signal cables from power cables by at least 12 inches or use separate conduits. Install twisted-pair or shielded cable with proper shield termination at one end only. Add EMI filters at PLC inputs.

- For ground loop issues: Establish single-point grounding systems. Use signal isolators to break ground loops between sensors and PLCs in different electrical zones. Install dedicated instrument ground systems separate from equipment safety grounds.

Step 4: Verify and monitor results

After implementing solutions, confirm that noise elimination is complete and sustainable through systematic verification:

- Document signal quality measurements before and after repairs using an oscilloscope.

- Run extended tests during all production modes to verify noise doesn’t return.

- Train operators to recognize early signs of returning noise problems.

- Set up automated monitoring using PLC diagnostic functions that track signal quality.

- Establish maintenance schedules for cleaning connections and checking shield integrity.

Cut through the noise with methodical troubleshooting

The facilities that excel at noise troubleshooting don’t just fix problems; they recognize patterns that predict where issues will develop next. When you understand how your facility’s electrical environment affects signal quality, you can design installations that prevent noise problems before they start. Teams that master these diagnostic skills spend less time chasing false alarms and more time optimizing the processes that drive production efficiency.