Tips for Servicing Overloaded Motor Starters in High-Demand Applications

Motor starters don’t get much attention when they’re working. But when they fail, everything grinds to a halt. In high-demand applications, motor starters take on constant electrical and thermal stress, making them prone to overload. Heat builds up, contacts degrade, and before you know it, downtime isn’t just a possibility — it’s a reality.

So, what’s the difference between a seamless operation and an unexpected shutdown? It comes down to knowing why overloads happen and how to prevent it. Here are the warning signs to look out for, and what to do when an overloaded motor starter needs servicing.

Understanding why motor starters overload

Motor starters are built to handle specific amounts of electricity, but tough conditions can push them past their limits.

One major issue is too much heat — when starters run at high power for long periods, the heat breaks down their parts and wears out the insulation, making them fail sooner. Starting and stopping frequently also causes problems by wearing out the contact points and internal coils, which makes the starter work less efficiently.

High-demand applications also tend to create voltage fluctuations. When voltage levels keep changing, the starter needs to work harder to keep up, putting more strain on the unit. And, of course, using a starter that’s too small for the job guarantees it will eventually break down.

While there are a variety of reasons a starter might fail, the good news is that an overloaded motor starter offers plenty of context clues before quitting. Here are a few of the most common signs of impending failure to watch for:

- Intermittent shutdowns: A starter that trips repeatedly or struggles to stay engaged is a red flag.

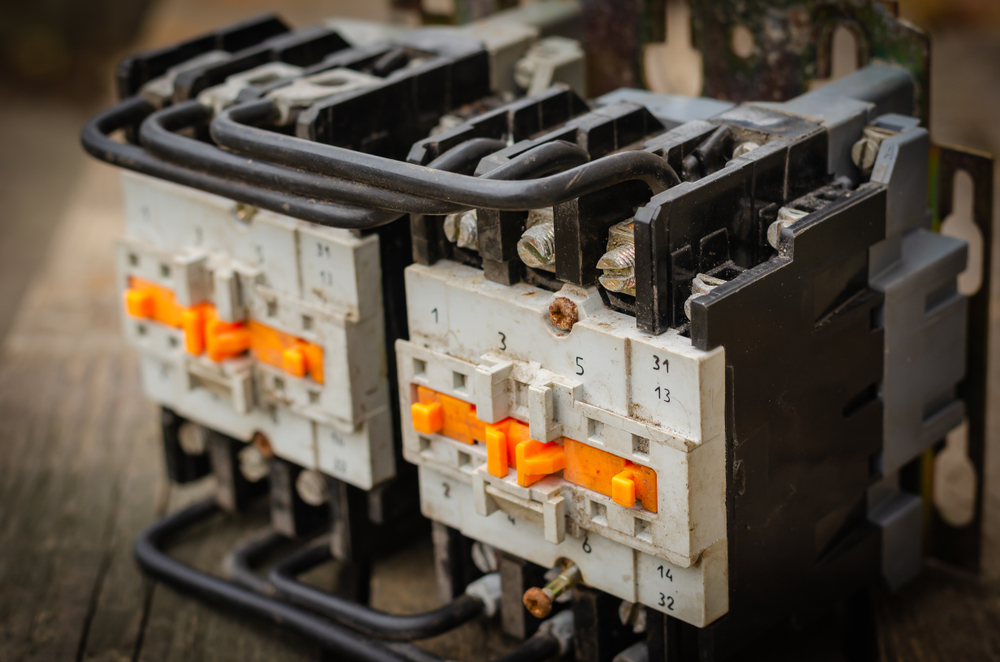

- Burnt or pitted contacts: Excessive arcing causes visible wear on contactors, increasing failure risk.

- Overheating: If thermal inspection shows unusually hot temps, internal components may be failing.

- Delayed engagement: A slow or sluggish starter suggests coil wear or excessive resistance in the circuit.

How to service and maintain an overloaded motor starter

If a starter is showing signs of stress, servicing it quickly can prevent a full-on failure. Here’s how to tackle the problem step by step and bring your starter back to peak condition:

- Shut down and inspect: Cut power to the starter and examine it for visible damage. Look for burnt wiring, melted insulation, or misaligned contactors.

- Clean the components: Remove dust, debris, and carbon buildup from electrical contacts. Even small contaminants can cause major resistance issues.

- Check the coil resistance: Use a multimeter to measure coil resistance. A significant deviation from the manufacturer’s specifications indicates a failing coil.

- Test voltage supply: Make sure consistent voltage is reaching the starter. Large fluctuations signal a bigger electrical issue that needs addressing.

- Replace worn parts: If contacts are pitted or coils are degrading, swap them out before they fail completely.

Let the experts handle it

Dealing with a defective motor starter? Now through the end of February, GES is offering 10% OFF single repairs or 15% OFF 3+ repairs of Allen-Bradley products, including motor starters and industrial motor controls!

Reliable repairs to keep your equipment moving

Even with the best maintenance, high-demand applications take their toll on motor starters. When you need repairs, fast and precise service keeps your downtime to a minimum. GES repairs and restores overloaded motor starters with precision, so they’re always ready for the workload ahead. Whether it’s replacing contacts, rewiring coils, or testing for voltage inconsistencies, we handle it all — so you can keep moving.