The Role of Power Conditioning in Protecting Automation Equipment

Automation systems are built for precision, efficiency, and reliability. But all of that depends on one thing — clean, stable power. Electrical inconsistencies, from voltage spikes to harmonic distortion, can silently wear down critical components. Power conditioning makes automation protection possible, filtering out disruptions before they reach sensitive equipment. Without it, your facility’s at the mercy of unstable power grids, unexpected surges, and hidden inefficiencies.

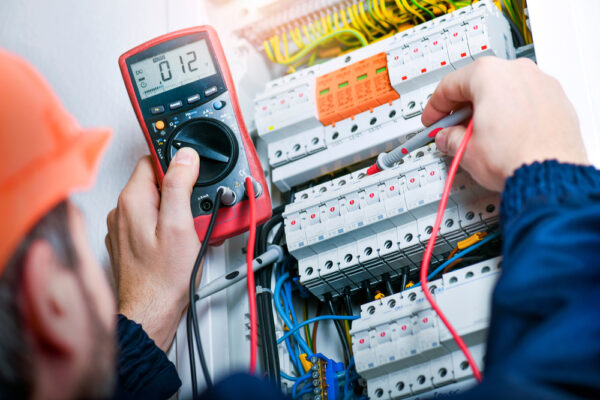

Identifying power inconsistencies

Power issues aren’t always obvious — and, in fact, they happen on a spectrum. Some failures happen suddenly and are easily identified; however, most come from repeated exposure to minor fluctuations that chip away at system integrity. Some of the most common types of power issues may go unnoticed until they cause significant issues:

- Voltage spikes and surges: Sudden increases in voltage — often caused by grid switching or lightning — can fry your equipment’s delicate circuit boards in an instant.

- Sags and brownouts: Low voltage conditions force motors, drives, and controllers to work harder. It quickly reduces their lifespan and increases heat buildup.

- Harmonic distortion: Electrical noise from variable frequency drives (VFDs), heavy machinery, or non-linear loads can interfere with automation signals and lead to erratic performance.

- Power interruptions: Even brief outages disrupt operations, forcing costly restarts and risking data loss in programmable systems.

How power conditioning protects automation

Power conditioning isn’t one-size-fits-all. Different applications require different levels of protection, but the goal is always the same — delivering clean, consistent power.

- Surge protectors absorb harmful voltage spikes. They’re the first line of defense, diverting excess energy before it can damage equipment.

- Voltage regulators stabilize fluctuations. Through power dips or spikes, regulators adjust voltage levels to keep automation equipment running within safe limits.

- Harmonic filters clean up electrical noise. By removing distortions from power lines, these filters prevent erratic behavior in automation controls and precision instruments.

- Uninterruptible power supplies (UPS) provide emergency backup. In the event of a sudden outage, a UPS gives systems the time needed to shut down properly or switch to an alternate power source.

Restore the integrity of power systems

If your sensitive electronics are affected by surges, spikes, interference, or other anomalies, GES can help. Now through the end of February, we’re offering 10% OFF single repairs or 15% OFF 3+ repairs of Allen-Bradley automation products.

Choosing the right power conditioning strategy

Power issues don’t affect every facility in the same way. Some environments require protection from the smallest voltage fluctuations, while others battle the intense electrical demands of heavy machinery. The right power conditioning approach depends on the specific risks your equipment faces daily.

A tailored strategy keeps automation systems responsive and protected from long-term damage. For example, high-sensitivity environments need full-spectrum protection. Industries like semiconductor manufacturing, medical device production, and data centers benefit from surge suppression, voltage regulation, and harmonic filtering. Similarly, heavy-duty applications need robust surge protection. Facilities with high-powered machinery, such as steel plants and paper mills, must defend against surges from large motor startups and switching events.

Investing in reliability with expert support

Power problems are frustrating. Along with shortening equipment lifespans, they drive up maintenance costs and create unpredictable downtime. GES helps facilities assess power quality risks and implement solutions that protect these critical automation investments.

From diagnosing voltage inconsistencies to repairing damaged components, our team ensures your automation systems operate at peak performance — without unexpected failures. Because where precision matters, power conditioning is an absolute necessity.