The Innovation Revolution is Coming to Manufacturing

The old saying goes, “necessity is the mother of invention.” When times are hard and people struggle, ingenuity reigns supreme. Good ideas percolate to the top and smart solutions come to fruition. Some of the best ideas, ventures, and inventions in history came from struggle. Why should the future be any different? The COVID-19 pandemic is an unprecedented struggle for manufacturers today, but it could bear the fruit of innovation that powers manufacturing into the future.

It’s no secret that manufacturing is struggling. Estimates and projections paint a poor outlook through the rest of the year and beyond. And although the rocky road ahead is all but guaranteed, what remains to be seen is how the manufacturing economy will adapt to it.

Necessity drives adoption

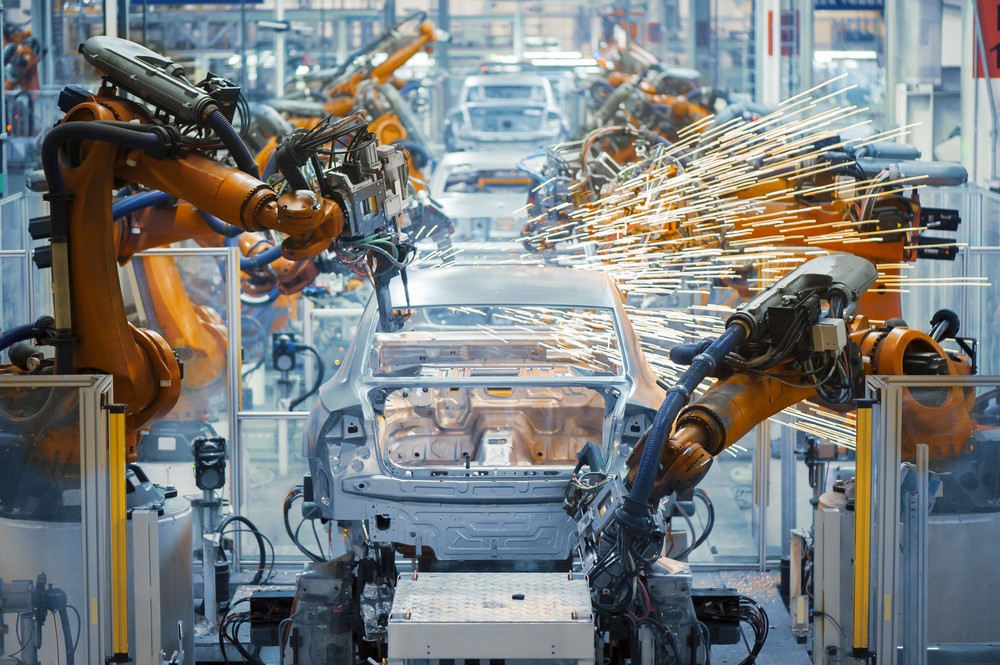

Manufacturing is on the cusp of some technological breakthroughs — innovations that will truly bridge the gap between the current environment and Industry 4.0. What’s needed to push them over the edge is a reason. COVID-19 may very well be that reason.

In a recent op-ed titled, Due To COVID-19, Manufacturing Will Experience Five Years Of Innovation In The Next 18 Months, manufacturing contributor Anna-Katrina Shedletsky argues that we could see rapid innovation, simply through forced adoption and deployment of technologies yet to roll out.

She argues a series of dominoes will fall in progressively more prolific innovations. Cloud data will unlock remote manufacturing oversight. The Industrial Internet of Things (IIoT) will increase automation. These examples and more will be fueled by necessity as manufacturers solve for distance. The technologies exist, they just have yet to be rolled out at-scale for many manufacturers. Now, there’s necessity driving adoption.

Innovation springs from adoption

As adoption of current technologies grows, manufacturers will quickly discover ways to put that tech to work beyond its current (limited) uses. And, as it happens, manufacturing already has a playbook to draw from — the technology sector.

For the past decade, Silicon Valley and technology startups around the world have appropriated existing technologies to fuel inventive iterations. The results are prevalent across the spectrum of industry today. Cash became credit cards, which then became an online money transfer option, and then an entire marketplace of digital cash transfer applications — and that’s just one example.

The fact is, the technology sector utilizes the same Lean approaches manufacturing does: Use what you have and strive for maximum return on investment (ROI). Where technology leads and manufacturing follows is in the iteration of Lean thinking into growth hacking — rapidly iterating on an idea to find as many applications for it as possible. Manufacturing has emerging technologies; now, it just needs to start applying them quickly, at-scale.

How will manufacturing innovate?

Manufacturing has many opportunities to grow through innovation. Not only are there early-stage technologies like blockchain, augmented reality (AR), and virtual reality (VR) rife for application, there are innovations in process and methodology to consider. Continuous improvement culture will spark process refinement, while research and development (R&D) will begin to trend toward connect and develop (C&D) partnerships.

COVID-19 is currently the biggest threat to manufacturing. But it might also be the catalyst for a renaissance of innovation that takes this sector decisively into Industry 4.0.