The Importance of Lubrication in Servo Motor Maintenance

The long-term efficiency of servo motors is closely tied to proper lubrication. Lubrication minimizes friction between internal components such as bearings, gears, and seals, preventing premature wear and overheating. In high-speed applications, where motors run continuously, the right lubricant ensures consistent performance by reducing thermal buildup and wear-related failures. Regularly applying the correct type and amount of lubricant, specific to the motor’s operating conditions, can make a measurable difference in industrial productivity and maintenance costs.

Servo motor lubrication: Basic principles

Lubrication plays a complex role in maintaining optimal performance and longevity in servo motors. By minimizing friction between moving parts, lubricants reduce wear and energy consumption while simultaneously dissipating heat from critical components.

High-quality lubricants also form a protective barrier against moisture and corrosive elements, extending the life of metal components. As lubricants circulate, they carry away small particles and debris, keeping internal motor parts clean. Proper lubrication also significantly reduces operational noise by smoothing the interaction between moving parts, contributing to a more efficient and quieter operation overall.

Choosing the right lubricant

As most industrial professionals already know, lubrication is never a one-size-fits-all deal. The most common types of lubricants used in servo motors include synthetic oils, greases, and in some specialized applications, dry film lubricants.

Choosing the appropriate lubricant is a must. Factors to consider include:

- The lubricant must maintain its properties across the motor’s operating temperature range.

- High-speed operations may require lubricants with low viscosity, to reduce breakdown.

- Heavy loads necessitate lubricants with higher capacity and better film strength.

- Factors like humidity, dust, and chemical exposure can influence lubricant selection.

- The lubricant must be compatible with all plastics, seals, and metal alloys.

Proper servo motor lubrication: Best practices

Several components in a servo motor rely on proper lubrication, each requiring specific attention and techniques:

- Bearings: Both ball bearings and roller bearings need regular lubrication to maintain smooth rotation and prevent premature wear. Use the manufacturer-recommended lubricant type and quantity, avoid over-lubrication to prevent increased friction and seal damage, and implement routine inspections to check for signs of inadequate lubrication such as increased noise or vibration.

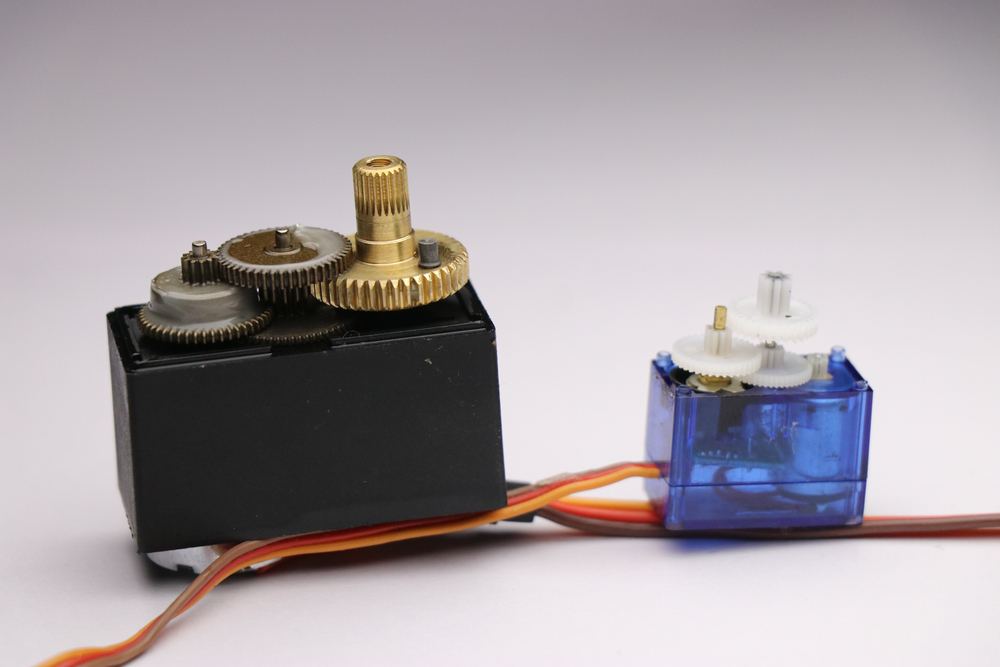

- Gears: In geared servo motors, proper lubrication of gear teeth is important for efficient power transmission and wear prevention. Select lubricants with appropriate viscosity for the operating conditions, ensure even distribution across gear teeth, and regularly inspect for signs of wear or lubricant breakdown.

- Shaft Seals: While not directly lubricated, these components benefit from proper lubrication practices. Avoid excessive lubrication that could put pressure on seals, keep the surrounding area clean to prevent contaminant ingress, and regularly inspect for signs of wear or damage.

- Feedback Devices: Some encoders or resolvers may require light lubrication to maintain accuracy. Use only lubricants specifically approved for these sensitive components, apply sparingly to avoid interfering with sensor operation, and follow manufacturer guidelines for lubrication intervals and methods.

Always adhere to the manufacturer’s recommendations for lubricant type, quantity, and relubrication intervals. And ensure a clean environment during lubrication, using filtered lubricants when possible. Monitor operating temperatures for unusual increases that may indicate lubrication issues. Act swiftly as anomalies arise.

Servo motor maintenance done right

As servo motors continue to find new importance in industry, the role of lubrication in ensuring their reliable operation becomes increasingly critical. Investing time and resources in a well-planned lubrication strategy isn’t just maintenance — it’s an investment in the long-term success of an increasingly robust range of servo motor applications!

SEPTEMBER DISCOUNTS ON SERVO MOTOR REPAIRS

Make your servo motor investments count! Partner with GES for expert servo motor maintenance and repairs. This September, we’re offering 15% OFF repairs for three or more servo motors or 10% OFF on any single servo motor repair.