The Impact of the Russia-Ukraine Conflict on Global Manufacturing

For the first time since the end of World War II, Europe is under siege as Russia pushes forward with its invasion of Ukraine. The two countries have been in open conflict since 2014, but now, military action on Russia’s part has escalated the situation to open warfare. Circumstances look more dire with each passing day, and countries around the world are taking decisive political, social, and economic action.

While the world watches war unfold in real time, many economists are already quantifying the impending fallout. A protracted war in Eastern Europe could spell profound consequences for manufacturing on a global scale.

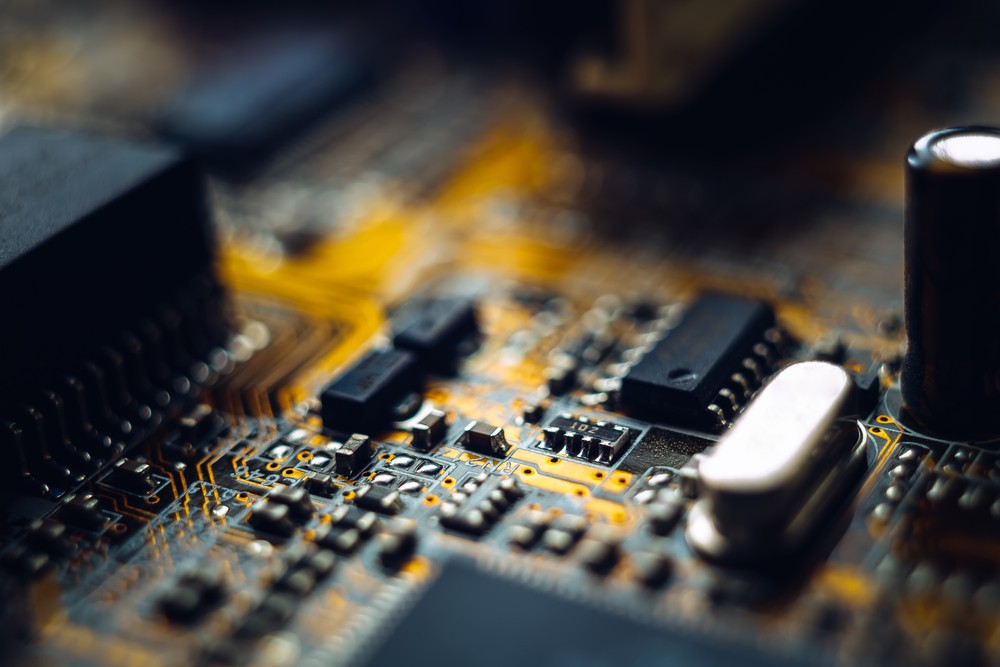

Ukrainian neon gas in semiconductor production

One of the biggest economic burdens on the world today stems from the lack of available semiconductor chips. Malaysia, South Korea, and China produce most of these chips, which creates a production bottleneck, and now, that bottleneck is getting tighter.

Neon gas is a crucial material in the production of semiconductor chips, and Ukraine is one of the world’s largest suppliers of neon gas. Russia is the leading producer of the gas, which is then refined in Ukraine. With the two countries at war, production and refinement has come to a standstill, so chip production is poised to slow as well.

Russian palladium in electronics manufacturing

Palladium is another critical component in semiconductor production — as well as broad electronics manufacturing. Here again, Russia is a leading producer and exporter. But with economic sanctions against Russia swiftly imposed and enforced, a significant source of the world’s palladium — as much as 33% — is now locked up for the foreseeable future. Russian palladium concerns have caused prices to skyrocket around the world. South Africa, another leading supplier, is unlikely to be able to keep up with global demand.

Ukraine as a supply chain bridge in Europe

Supply chains will face more disruption the longer the war goes on. Ukraine is the European gateway to the East, with both ports and borders critical to global supply chains. While the country remains under siege, these ports and borders are closed, forcing manufacturers around the world to adapt their supply chains or deal with delays.

As one global supply chain expert says, “Because of Ukraine’s location it is one of the biggest — and likely one of the most overlooked — cogs in the global supply chain today.” It has direct ties to the German, Turkish, Polish, and Chinese economies, and serves as a steppingstone for numerous other trade routes.

Oil and gas disruptions stunt supply chains

One of the primary drivers behind the Russian invasion of Ukraine is control over natural resources — specifically, oil and natural gas. As countries across Europe place sanctions on Russian energy initiatives, global manufacturing will face ramifications. Prices for these commodities are already rising sharply and creating downstream cost increases for manufacturers across sectors. It’s yet another strain in an already stressful inflationary environment.

The push for a swift conclusion

While there’s no telling how long the war will last, it’s clear the world’s manufacturing economy will face more significant disruption as the conflict continues. Manufacturers should brace for protracted effects, and do what they can to safeguard themselves from downstream impact. And, most importantly, we should all hope for a swift and peaceful resolution to prevent further loss of life.