The Global Semiconductor Shortage is Growing Dire

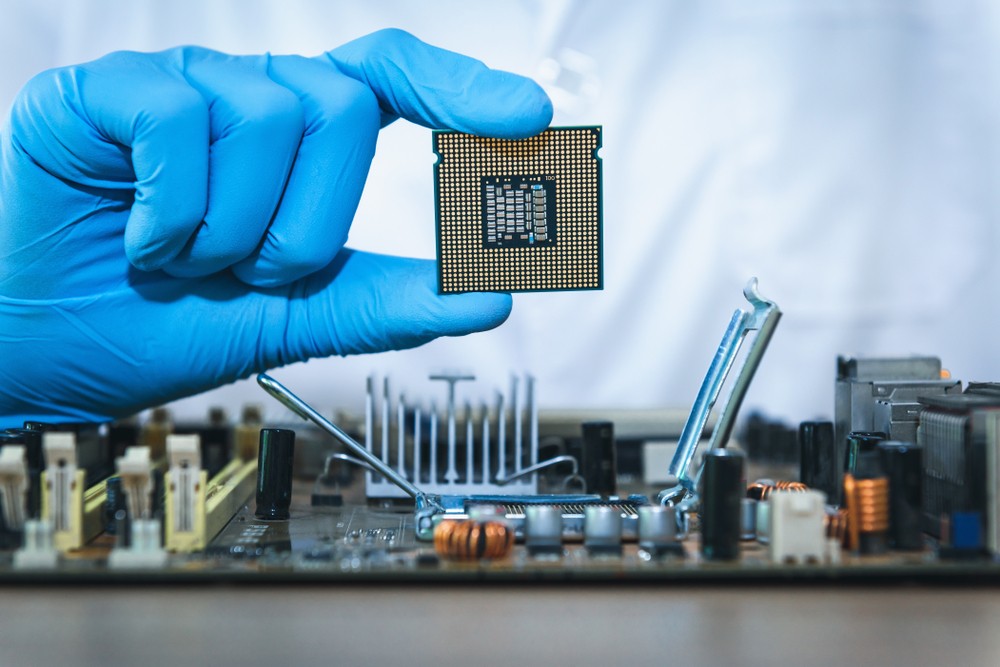

Supply chain issues have persisted in spite of general economic recovery since mid-2020. One of the most in-demand items these days is also one of the most inaccessible: semiconductors. These essential components are in virtually every electronic device, which makes them vital to the production of some of the most important discretionary consumer goods. With a one-year lead time normally, orders placed in 2020 that should be coming due, aren’t. It’s a big problem that’s becoming worse with each passing week in 2021.

How did we get a global semiconductor shortage?

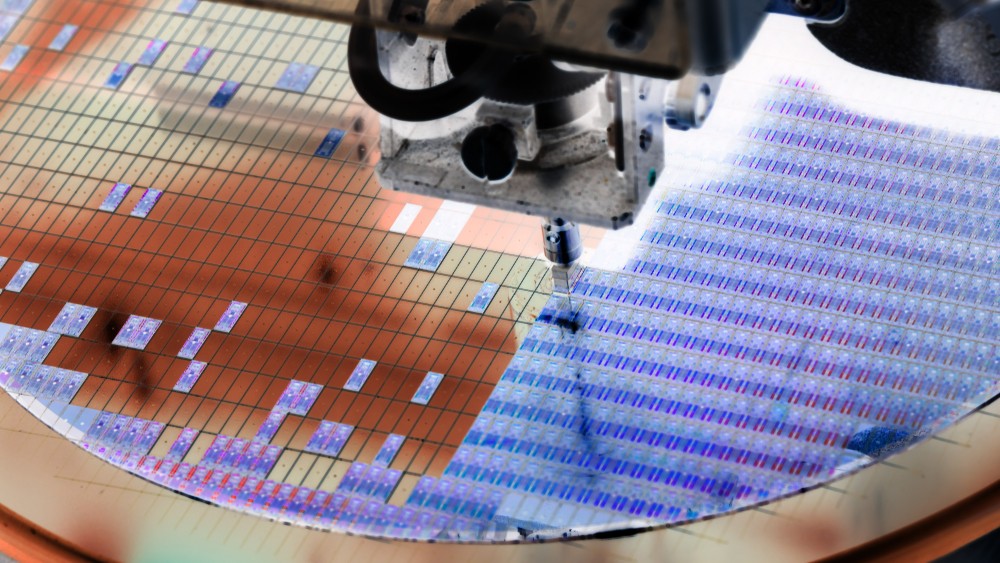

The global semiconductor shortage is the product of a perfect storm of variables. First, the world’s global semiconductor output is largely consolidated in Asia — specifically South Korea, China, and Taiwan. These areas have dominated the market, forcing many other countries and regions out and consolidated exports to a fewer number of players.

To make things worse, semiconductor lead times are roughly a year, which would put the origination for today’s fulfillment approximately a year back: right at the outset of the pandemic. Producers still recovering from labor shortages aren’t able to keep pace with this demand. This leads into a larger conversation about supply chain failures.

Finally, materials shortages are rampant, which has slowed the production of semiconductors. The products that are being made come at a hugely inflated cost. All together, these variables make semiconductors nearly impossible to get ahold of today.

Production grinds to a halt

The widespread application of semiconductors across virtually every market has led to disastrous consequences for producers who can’t source them fast enough. Large automakers like GM and Ford have completely shut down product lines due to the shortage. Other companies are either eating inflated costs or passing them to customers.

Everything from gaming consoles to home appliances are facing stoppages in production due to semiconductor sourcing issues. And, according to supply chain experts, these sourcing issues are likely to continue through the end of the year.

An opportunity for reshoring?

With a majority of semiconductor manufacturers operating overseas, manufacturers are calling for reshoring efforts to bring control over production closer to home. Currently, the United States controls just 12% of the world’s semiconductor production. Bringing supply chains back to domestic soil could restore the reliability, pricing, and efficiency many technology manufacturers are sorely missing today.

Unfortunately, the problems don’t end with reshoring. The Texas cold snap put U.S. chip producers like NXP, AMD, and Qualcomm behind the eight ball. Moreover, the cost of domestic production would likely be much higher to account for supply chain stability. Chip makers are lobbying the Biden White House for subsidies and incentives to make domestic manufacturing a more appealing prospect, but so far there’s been no committal.

An end in sight?

There are a few things that need to happen before the semiconductor shortage becomes a surplus. For one, material prices need to pull back to normal levels. Then, supply chains need to congeal again. Whether production stays central to Asian countries or becomes more diverse as a hedge against this same problem in the future, manufacturers still need to adapt to growing demand. As more and more products become “smart,” demand for semiconductors will only grow.