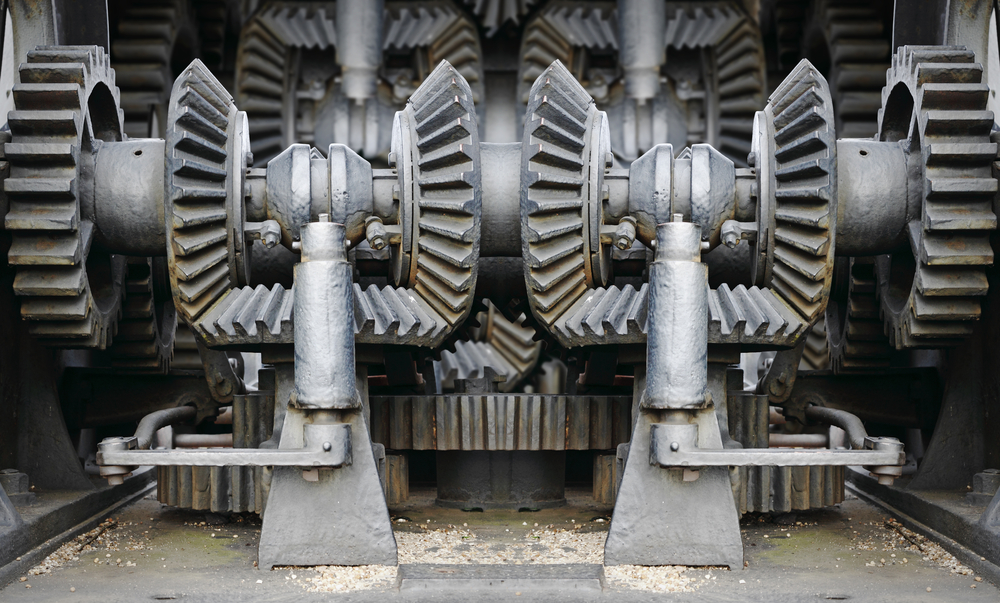

Techniques for Maintaining Gearboxes in High-Stress Environments

Gearboxes are built to withstand pressure, but high-stress environments can push them to their limits. Constant operation under heavy load and extreme temperatures takes a toll, threatening performance and longevity. Without proactive intervention, equipment gearboxes will face the consequences of unchecked duress.

So how can you guarantee the efficiency and reliability of a gearbox under the toughest conditions? Rely on these techniques to help you stay ahead of wear and tear, to keep your equipment moving smoothly.

Reliability starts with regular inspections

Spotting issues early is the foundation of effective gearbox maintenance. Routine inspections help you identify small problems before they become costly breakdowns. Here’s what to build into a routine inspection regimen:

- Check for leaks or unusual noise: Gearboxes should run smoothly and quietly. Leaks or grinding sounds usually point to vibration and/or wear and tear, misalignment, or insufficient lubrication.

- Inspect seals and housing integrity: In high-stress environments, seals can degrade faster, letting contaminants like dirt or water into the system. It can lead to lubrication breakdown and premature wear.

- Examine gear teeth closely: Chipped, worn, or misaligned teeth can create cascading issues, putting added stress on the entire assembly. Early detection prevents more extensive damage.

Lubrication is an ongoing strategy

Lubrication is critical anywhere there are moving parts. A properly lubricated gearbox is a reliable gearbox, but there’s more to it than simply making sure gears are greased. Properly lubricate with these tips in mind:

- Choose the right lubricant: Standard oils might not cut it under extreme loads or temperatures. Be deliberate in your choice of lubricant. High-viscosity lubricants and synthetic oils are better suited for demanding conditions.

- Check oil quality regularly: Contaminants reduce an oil’s effectiveness. A simple oil analysis gives insight into both lubricant health and gearbox wear.

- Maintain proper lubrication levels: Too much oil creates drag and excess heat, while too little won’t protect gears adequately. Strike the right balance for efficiency.

Temperature control is non-negotiable

Heat is a gearbox’s worst enemy in high-stress environments. It degrades lubrication and accelerates wear. Over time, it completely compromises structural integrity. Avoid downtime by:

- Installing cooling systems: Heat exchangers or fans help maintain stable temperatures during continuous operation.

- Monitoring temperature trends: Sudden spikes can signal internal issues like gear misalignment or bearing failure. Sensors and thermal imaging tools offer real-time insights.

- Insulating gearboxes when needed: In cold climates, insulation helps gearboxes warm up faster, reducing startup strain and avoiding lubrication thickening.

Keep a close eye on alignment

Alignment issues are always lurking in high-stress environments. Even minor misalignments between the gearbox and connected machinery create enormous strain. Here’s how to square up connections:

- Use laser alignment tools: They provide precision far beyond manual adjustments, keeping your gearbox perfectly positioned for optimal performance.

- Recheck alignment after heavy use: Shifts in foundations or prolonged vibration can nudge components out of place, even if alignment was correct initially.

- Consider thermal expansion: Gearboxes exposed to extreme heat may shift slightly due to expanding components. Regular monitoring helps you maintain proper alignment under high-temperature conditions.

Persistent gearbox problems?

Don’t let gearbox maintenance fall by the wayside — especially during colder months. Now through the end of the year, GES is offering 15% off repairs on 3 or more pieces of equipment! We’ll take care of your gearboxes and any other mission-critical components, so you can start the year off strong.

Proactive maintenance saves you from more than reactive fixes

The best way to maintain gearboxes in high-stress environments is to stay ahead of issues. Proactive steps like detailed inspections, oil analysis, and regular alignment checks cost less in the long run than emergency repairs or replacements.

When your maintenance strategy is customized to your environment, gearboxes can thrive even under constant pressure. Consistency is key, and every preventive measure you take translates to smoother operations and fewer breakdowns — and that means greater peace of mind.