Types of Servo Motors

Motors are the backbone of many different industries. They’re prevalent in everything from mechanical processes and manufacturing to retail products. While motors are useful for thousands of applications, some types can complete tasks that no other kind can handle. One such variety is the servo motor.

Servo motors are small, electric, efficient and capable of many jobs other motors can’t do. They are essential to many manufacturing companies as well as innumerable machines and modern tech items. From simple appliances to advanced robotics, servo motors are invaluable. This guide will explain the different types of servo motors, the jobs they accomplish and how they work.

What Is a Servo Motor?

A servo motor is a small motor that runs on an electric current, sometimes also referred to as a controlled motor. It has an actuator that is either linear or rotary, allowing it to produce a forward and backward motion or rotational motion. It allows for precise control of the velocity, acceleration and angular positioning. Servos serve a different purpose as compared to industrial motors, as they aren’t designed to provide energy conversion. Rather, servo motors are types of variable speed drives.

While they are technically motors, they don’t fall into any particular class. Servos typically have small diameters but long rotor lengths, and they have low inertia. This combination of elements provides it with the perfect construction to produce high-speed responses and precision control when prompted.

Various industries mainly use servos in building and production technology, or any machinery that helps their manufacturing workflow. But they also play a significant role in many different retail products, such as computers, mechanical toys and various other tech items. Among the many advantages of servo motor use, they can provide anything from simple motion to complex control with efficiency, making them incredibly versatile for hundreds of applications.

The design of the servo motor lends itself to delicate and detailed applications, such as motion control, accurate positioning, quick reversing and overall precision. Since they’re designed for exact positioning and power, many industries make use of servos, including robotics and computers, radar production, automation in manufacturing and machine tools, as well as in CNC machines, tracking systems and many other products.

How Does a Servo Motor Work?

Servo motors are notoriously small but mighty. To understand exactly how the servo motor works, it’s best to get acquainted with the parts and pieces first. The internal elements are relatively simple. The servo contains a small motor, potentiometer and control circuit contained within a servo case. The exterior of the case holds the output spline and drive gears, which attach to the internal circuit. The gears also attach the internal motor to the control wheel, and there are three main wires — power, control and ground.

To work, the motor rotates, changing the amount of resistance in the potentiometer, and the control circuit regulates the direction and power of the movement. As it moves, the shaft of the servo shifts into position. Once it reaches the desired goal, transmitted through the signal wire, the motor stops. It has an internal sensor to send position feedback so that the motor knows precisely where to stop.

Proportional control determines the speed of the motor, meaning it depends on the distance between the shaft position and the end goal. In simpler terms, the closer the motor is to the desired position, the slower it moves into place. The further it is, the faster it goes. Proportional control ensures the motor remains efficient, only operating as hard as necessary to accomplish the desired result.

Beyond the internal mechanisms, several types of electrical pulses with varying widths move the servo via the control wire. The pattern is referred to as pulse width modulation (PWM). PWM consists of a minimum pulse and maximum pulse, regulated by a repetition rate. As the PWM reaches the motor through the control wire, the pulse duration turns the rotor and adjusts the shaft positioning. The length of each pulse turns the motor the corresponding distance.

As far as the turning distance goes, servo motors typically have a range of about 180 degrees — 90 degrees in opposite directions of the neutral position. The neutral position means the point where the servo has the same potential for motion both clockwise and counterclockwise, which sits at 90 degrees.

Servos will hold a specific position for as long as they are prompted to move by the provided pulse. If the servo meets an external force pushing in the opposite direction, the servo will continue to hold its orientation. However, the servo is only able to exert a maximum amount of force, also known as its torque rating. The specific measurements depend on the type of servo motor.

Servo Motor Applications

Since servo motors are small, efficient and fill such a particular need, they’re useful in many different industries and for multiple purposes. There are also several different sizes and types of servos, all capable of completing specific sets of jobs. They’re excellent for general uses as well as specialty implementations, such as precise position control. Servo motors are a part of everything from industrial machinery and aircraft to children’s toys and remote control hobby models.

Servos are essential in many ways and provide a range of uses, including:

- Robotics: Robotic technology requires many moving parts, all of which need to be capable of precision and controlled power. Servo motors are necessary for modern robotics, as they perform a variety of functions, depending on the machine’s intended task and purpose. One of the most important roles of servos in robots is to control the action arms, allowing its programmers to move them to exact angles and locations.

- Cameras: Most modern cameras are relatively compact, so any internal control mechanism has to be precise and small. Servos fit the bill perfectly, serving purposes such as controlling the lens to adjust the focus. It also allows you to either manually tune the lens or set it to automatically shift if the sensors detect the image is out of focus.

- Automatic doors: One piece of technology that many may overlook is the automatic door. Servos drive automatic doors to open and close when approached, everywhere from supermarkets to hospital facilities.

- Conveyor belts: Beyond public applications, such as in grocery stores, conveyor belts are essential to many manufacturing facilities and production lines. Servo motors are what control the belts to move, start and stop at specific stages, which is necessary for things like bottling and product packaging.

- Vehicles: While robotic machinery mainly relies on arm functionality, robotic vehicles also need to move from place to place with accuracy. Programmers control the motion of these vehicles through servo motors, which can determine speed, direction, torque and when and where the robot starts and stops.

- Solar tracking: Solar panels are becoming more prevalent as companies and individuals look for greener energy alternatives. To make the most of solar energy converters, they need to directly face the sun as it moves across the sky. Through the use of servo motors, users can program the angles of the panels to shift towards their light source throughout the day.

- Milling: When it comes to milling processes, precision is key. Servo motors help milling machines accurately cut and form materials at an efficient pace.

- Textile production: Producing textiles requires a significant amount of delicate weaving and spinning with both sensitive and resilient materials. Knitting and sewing machines use servo motors to accurately control their speed, power and accuracy to ensure uniformity throughout the fabrics.

While these applications represent a varied range of uses, there are still many more, ranging from toys to complex computer systems. They’re far more delicate and programmable than other motors, making them a necessary part of many industries and manufacturing processes.

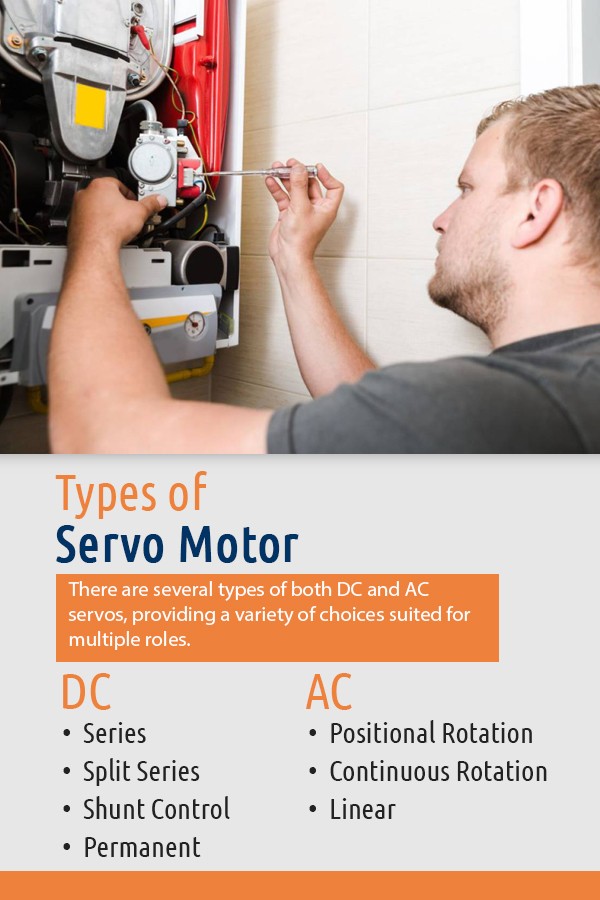

Types of Servo Motor

There are two primary varieties of servo motor based on the current surges they accept — DC and AC. The primary differences between the two include the currents that control them and their ideal applications. Additionally, DC servo motors are typically less costly as compared to their AC counterparts.

There are several types of both DC and AC servos, providing a variety of choices suited for multiple roles.

DC

DC servo motors are controlled by DC currents. They’re designed to handle smaller current surges, making them well suited for smaller, more precise applications. Each servo consists of a DC motor, gearbox, feedback potentiometer, electronic circuit and feedback control loop. It contains a DC source within the armature winding field, and the servo archives control by either altering the field or armature current.

These servos can provide quick reactions to commands and highly precise motions, making them perfect for machines programmed with mathematical controls. But they can have more stability problems and require more maintenance than AC servo motors. However, DC servo motors are the more efficient variety. Within the category of DC servo motors, there are several specific models, including:

Series

Series DC servo motors draw a large current and provide a high starting torque. However, they typically have poor speed regulation. You can reduce the efficiency of a series servo through split series field winding to overturn the field voltage. This result is also referred to as turnaround.

Split Series

Split series servo motors provide the functionality of an individually energized field controlled motor. They have a split-field rate with partial or fractional kilowatts and have the common curve for torque and speed, unlike the series. The curve represents the rapid reduction of torque in association with higher speeds, as well as a high stall torque. The result is excellent damping.

Shunt Control

Shunt control servo motors have two independent windings. The first is the field winding, which is located on the stator. The second is the armature winding, located on the machine’s rotor. Both of these windings connect to a DC source in a parallel formation.

Permanent

The permanent variety of DC servo motor is also referred to as a permanent magnet shunt motor or a permanent excitation motor. While it performs similarly to an armature-controlled fixed field motor, a stable magnet supplies the field necessary for it to run.

AC

AC motors are controlled by AC currents. These servos can handle higher current surges than their DC counterparts, making them better suited for industrial machinery purposes. Within the motor, there is an encoder, providing the capacity for closed-loop control and feedback. They’re also less prone to stability problems and require less frequent maintenance as compared to the DC variety.

AC servos are capable of accurate control and have advanced designs to provide significantly improved torque. Because of this, these motors are most frequently used in CNC machinery and automation. Within the category of AC servo motors, there are several specific models, including:

Positional Rotation

One of the most prevalent servo motors, the positional rotation variety, is used in many applications. It has a shaft output that rotates at a maximum of approximately 180 degrees and includes several physical stops within its gear mechanism. The stops provide a buffer for the turning motion, preventing it from exceeding the limit and protecting the rotation sensor. Positional rotation servos are essential parts of aircraft, robots, radio-controlled vehicles and toys, among other products.

Continuous Rotation

The continuous rotation servo motor operates similarly to the positional rotation model, but it is less limited. This servo can move in any direction for an indefinite distance. The control signal also functions differently. Rather than direct the motor to a static position, it works to control which direction it rotates and how fast. The range of command is limited to these two factors and allows you to change directions on command.

With unlimited rotation and directional control, this type of servo motor is best for applications such as radar dishes or as the drive motor for a robot.

Linear

Also close to the positional rotation servo motor is the linear servo motor, which maintains similar functionality. It has the same rotational capacity, but the servo also has added gears that allow it to move in a linear pattern — forward and backward. They aren’t typically found in as many applications as the continuous and positional rotation motors, but some hobby stores sell them individually as actuators in model airplanes and small vehicle builds.

Get Quick Servo Repair With Global Electronic Services

A breakdown in your manufacturing line or one of your machines can be a significant detriment to your company. At Global Electronic Services, we can repair or replace components of your servo motors fast to minimize your downtime. Our professional technicians will go through the process of inspecting, testing and restoring your damaged servos and provide you with the help you need at an affordable price. With 24/7 availability and rush service, you can preserve your uptime and keep your servos running smoothly.

Trust Global Electronic Services for your servo motor repair needs. If you have questions, feel free to ask a technician or request a quote.