Resonance is a Silent Killer of Manufacturing Equipment

If you’ve ever used a tuning fork, you’re familiar with the concept of resonance. Slapping the tuning fork on your palm to produce a frequency you can use to tune an instrument is a great example of resonance — as well as a positive one. In manufacturing, though, resonance doesn’t have such a positive perception. In fact, resonance can become a massive problem for producers, necessitating major repairs and frequent maintenance.

Resonance in the factory

Put simply, resonance is sensitivity to vibration frequencies. As a property of any mechanical element — including machinery like electric motors, pumps, turbines, and more — the sensitivity becomes a problem when vibrations from a machine’s operation are intensified by resonance.

Almost any source of vibration can cause resonance, including misalignment, vibration, or unbalance. And even minor resonance can damage machine components, resulting in enough wear and tear to cause catastrophic failure.

The problem is, most machines generate vibration that creates a natural frequency, inevitably leading to resonance. As the vibration within the machine amplifies, it can cause a host of problems, such as bearing failure, weld or fastener failure, product quality issues, and more.

Signs and symptoms of resonance damage

How can you tell whether your machines are under immediate threat of resonance damage? Even if you can tell something is wrong with a particular machine, it can still be challenging to pinpoint resonance as the problem, especially if it occurs only at certain parts of the day when the machine is running at a specific speed.

The best way to detect resonance is by continuously monitoring each machine over time. Follow these steps to effectively detect resonance:

- Failure mode and effects analysis (FMEA) and root cause analysis. If your machines are vibrating excessively and showing signs of bearing failure, cracked welds, or unbalance, resonance might be the cause. Depending on the machinery you have, perform a vibration assessment, pulsation assessment, bump test, and other assessments to determine if resonance is the root cause of the problem.

- Continuous diagnostics. Monitor speed information on all machines to detect any unbalance forces with rotating components. As you gather data on the full vibration spectrum of the machine, you can fully understand a machine’s response to them.

- Sweep test. A sweep test is an easy way to detect problematic frequencies so you can determine if resonance is a problem in a particular machine. It requires you to manually sweep the machine through a frequency range, taking readings at each step.

Resonance prevention in the age of the IIoT

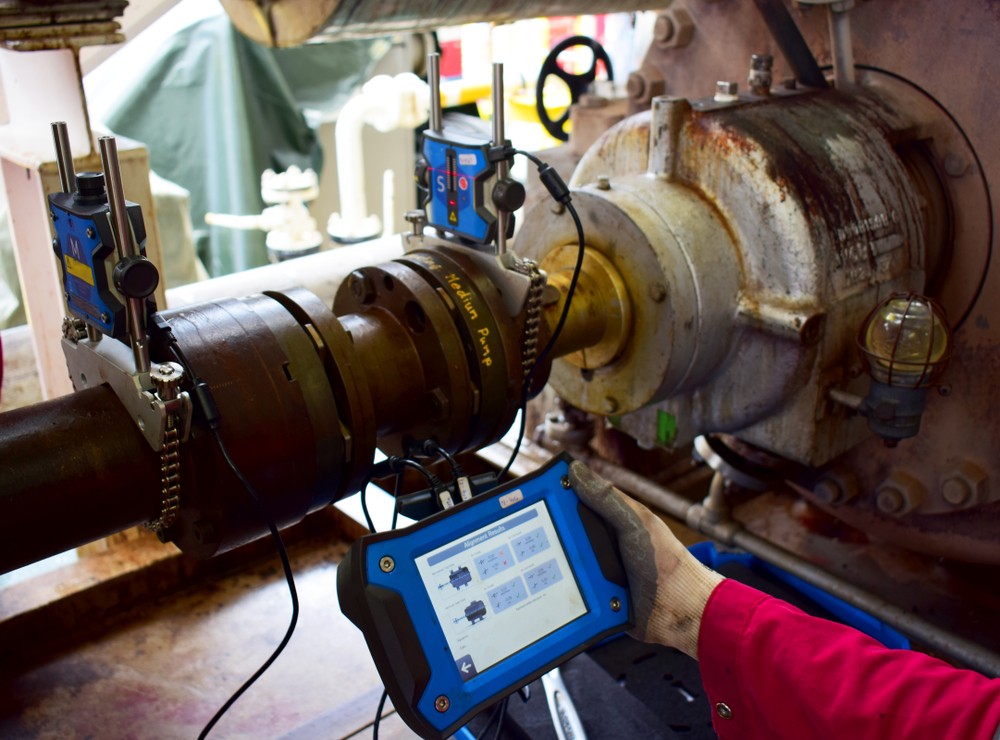

Resonance is a constant concern wherever industrial equipment is operating, but it can be addressed using modern technologies. Not only are there vibration sensors to help identify resonance-generating problems; certain Industrial Internet of Things (IIoT) sensors and affiliated software can anticipate resonance based on equipment configuration.

It’s important to note that even if a piece of equipment shows signs of resonance, it may not reach damaging amplitude levels. Continuously monitoring for resonance through an IIoT solution can help your team determine if or when a fix is needed so you’re not blindsided by this hidden, yet ever-present risk.