Repairs Versus Replacements: An Objective Look at Industrial Machinery Costs

When you crack your smartphone screen, you have to ask yourself an important question: Do I have it repaired, or should I replace the whole thing? While this decision is ultimately a trivial one, it does make us think more carefully about how to deal with large-scale manufacturing machine problems.

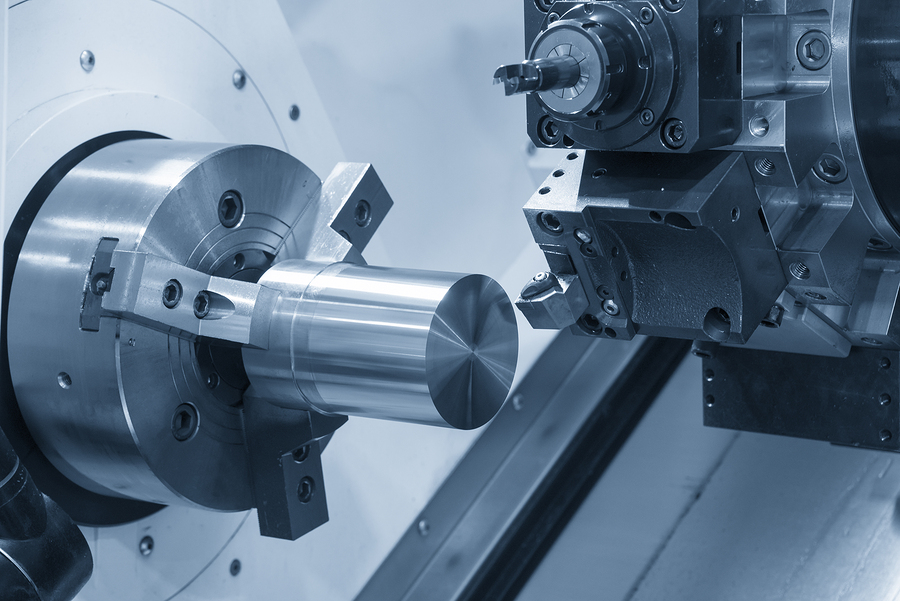

What happens when your CNC machine suffers a severe failure? How do you proceed when an injection molding machine requires a series of high-cost repairs to make it functional again? What’s the best course of action when your DC motor fails after years of hard use?

Factory maintenance managers must make executive decisions about machinery each and every time a problem arises. The nature and severity of the problem will often dictate their courses of action but, ultimately, it’s important to make decisions that get machines back up and running again as quickly as possible.

In some cases, it comes down to the cost of repairs versus the cost of replacements.

The argument for repairs

Repairs are frequently a first course of action in the event of downed machinery — and for good reason: The cost versus the benefits just make sense. If your three-year-old $34,000 CNC machine breaks down and needs $2,000 worth of repairs, it’s a much smarter solution to pay for the repairs than to buy a whole new unit. The machine likely has more good years of production and you have far fewer maintenance costs to worry about compared to the cost of buying new.

Repairing is also quicker than installing new machines and offers benefits from not requiring retraining or reinstallation. And the biggest advantage to repairing machinery instead of replacing it is in the ability to resume production quicker. Maintenance managers know malfunctioning machinery doesn’t just incur repair costs: It’s also responsible for the loss of revenue stunted production causes.

The argument for replacement

Replacing industrial manufacturing machinery incurs no small cost. Looking at CNC machines for example, the cost of a CNC table can run anywhere from a few thousand dollars to almost a hundred thousand dollars, depending on its features and capabilities. This in itself is a barrier to replacement.

But looking at the price tag of a replacement machine doesn’t provide a clear picture of whether or not it’s a good investment. Here are a few additional questions that can tip the scales more in favor of replacement:

- How old is your current machine? How many years of service does it likely have left?

- What will repairs to your machine cost versus the cost of financing a new one?

- If you choose to replace, will you purchase outright or finance?

- What features does a new model have? What impacts could the combination of replacement time and those additional features have on production in the long term?

Looking at both the financial position of buying a new machine and the potential for it to impact your production capabilities means getting a truer sense of the investment you might end up making.

Even more factors can push manufacturing leaders toward making new investments. Ending the fiscal year with an excess of funds means having the opportunity to reinvest them in the business. A new contract with extenuating demands can make upgrading machinery a smarter long-term option than simply repairing.

Making a sound decision

When machinery breaks down, the choice to pursue repairs is often the best solution. But it’s important to remember it’s not the definitive solution in every case. Dealing with a machine that’s old, has a consistent track record of problems, and that’s responsible for measurable lost revenue may be a candidate for replacement — especially if there’s available capital.

The next time you’re dealing with a troublesome machine on the floor, step back and look at it objectively. What’s the best solution for your business? Is it to repair or replace?

When you’re in need of a repair, you can always count on the professionals at Global Electronic Services. Contact us for all your industrial electronic, servo motor, AC and DC motor, hydraulic, and pneumatic needs — and don’t forget to like and follow us on Facebook!