Why Repair Industrial Electronics Instead of Replacing with New Ones?

-Repairing Industrial Electronics can save you at least 60% of the cost of a new unit-

In the world of Industrial Electronics most people think of one thing when their line goes down in the middle of production…get the bad unit out and order a new one as fast as possible. It is our natural first thought to think that if something is bad, we must put a new one in its place. Here’s two very important factors to consider when it comes to replacement of industrial electronics that are in need of repairs:

Cost – At the end of the day our decisions must be determined by how much money we are losing while production is down. Often the cost of what it takes to get back into production seems unimportant while we are down and losing significant amounts of money by the hour. Buying a new replacement unit is the first logical thought we have and we go to work trying to source where we can buy another unit. This may be an easy task if the machine in you production line is current and readily has replacement options in stock, however this is usually not the case. Machines in production lines that go down are often breaking down because of age, and this usually means the has replaced your old model with a newer one that uses different software and now has a smaller, more modern frame. This is not good when you’re looking for a drop in replacement to get you back up and running quickly. However, for what is usually a significant amount of money you can purchase that unit along with a complete retro fit to all or certain parts of your production line. This can be very costly and end up needing several of the machines OEM engineers on site at your facility. They charge you hourly just to load and introduce your machine to the software it requires to communicate with the upgraded unit.

Time – While it seems that ordering a quick replacement will save you time, that is not necessarily the case. Sure in a perfect world we can quickly call and overnight or same-day deliver an exact replacement, but then you discover your required equipment is obsolete, out of stock, only built to order or only available overseas. Often times the seller is in another time zone and their business hours are closed when you’re in need.

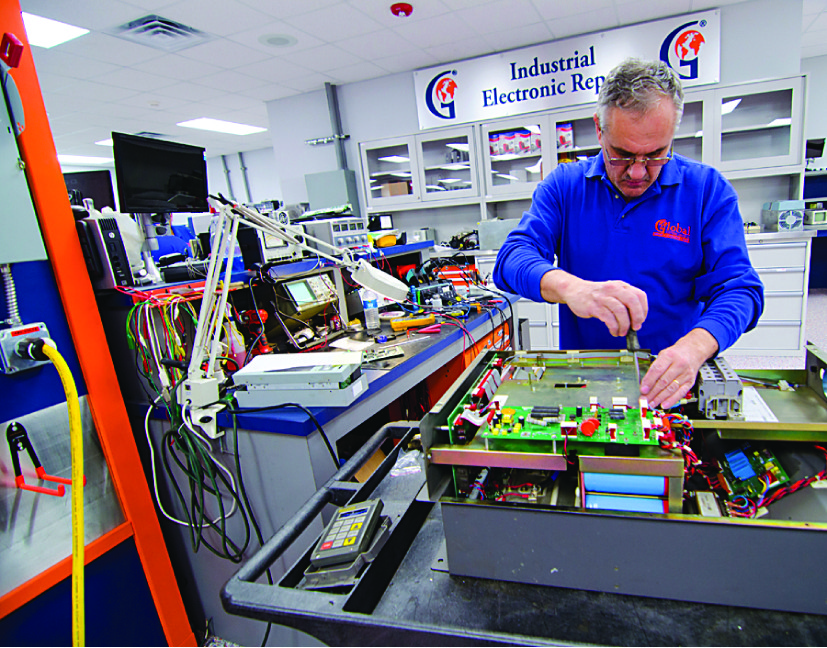

Having your unit repaired is the number one solution to cost and time issues. Repairing a unit will typically save at least 60% off of the cost of a new unit, sometimes much more. Global Electronic Services stocks millions of common failure parts and can often turn around a repair the same day or within 24 to 48 hours. Our free rush service is definitely worth considering when you’re in a time crunch. You will also receive an 18 month in-service warranty which is usually more than double the warranty time period of a new unit. Why would you not choose to repair?

The best decision you can make to get your manufacturing line back up and running is to have your unit repaired whether its overnight using our FREE rush service or having it couriered and waiting on it for a same-day turn around. And, to order another unit, like a refurbished or rebuilt unit so that you can have a spare in case you ever go down again! Let’s face facts, we all know that production lines go down, knowing your repair options will keep you at minimal downtime! Please share your comments or questions with us below and be sure to visit gesrepair.com or call us at 1-877-249-1701 to learn more about our repair services. We repair Industrial Electronics, Servo Motors, AC and DC Motors, Hydraulics and Pneumatics.