Disconnect Switches

What Is a Disconnect Switch?

Disconnect switches, otherwise known as safety switches, allow the user to isolate an electrical current by interrupting its flow. This rapid disconnection of the power flow is ideal for emergency shutdowns, switching to an alternative power source or routine maintenance.

The disconnect switch usually has three components:

- – Enclosure: The enclosure serves as a safeguard to protect the user from coming into contact with live circuits and protects the circuit itself from external hazards.

- – Wired electrical contact and actuator: These two components work together within the disconnect switch. The actuator is typically something like a handle or a key that allows the user to engage or disengage the contacts without ever exposing themselves to danger by opening the enclosure.

The disconnect switch is more than a safety recommendation — it’s a regulatory mandate. The National Electrical Code (NEC) article 430.102B requires that workers should be able to see a disconnect switch within 50 feet when working with manufacturing equipment or motors.

-

Allen-Bradley

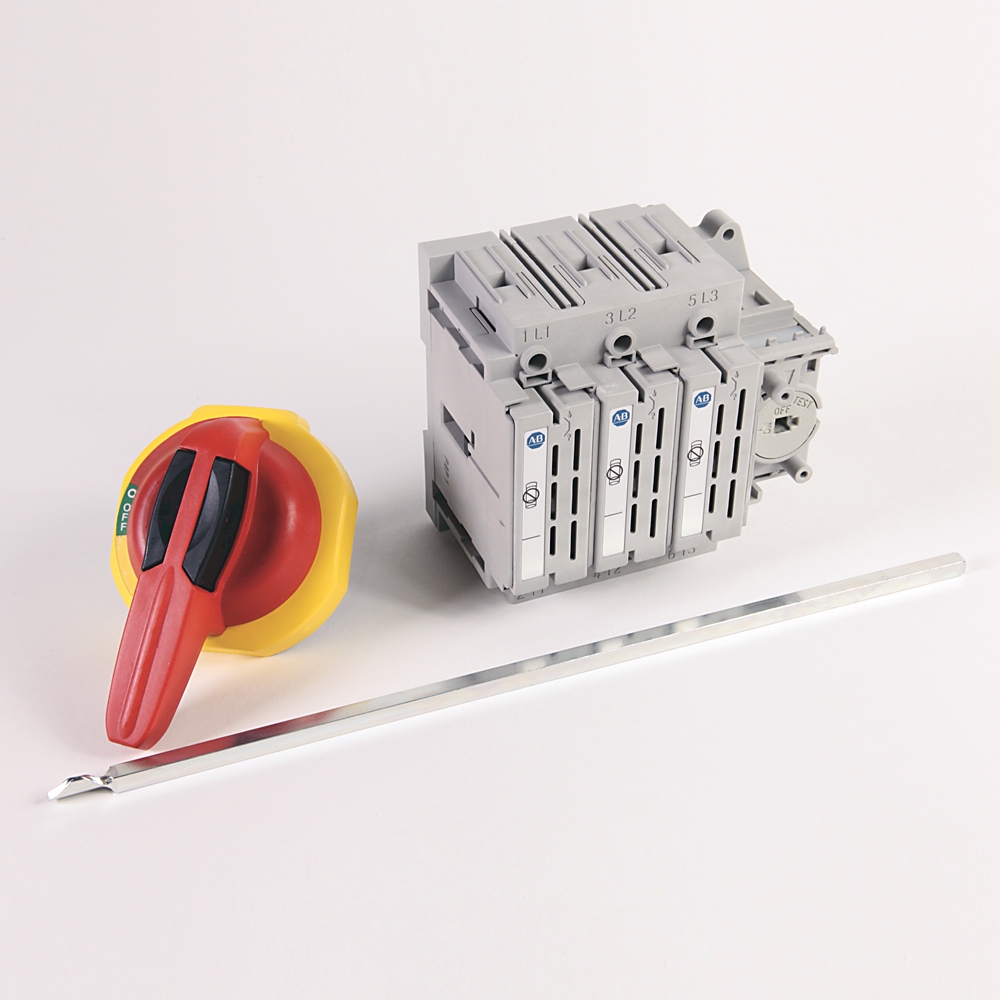

Allen-Bradley194R-NE160-1753: Allen-Bradley Disconnect Non-Fused IEC 3 Poles 160A

- Model #:

- 194R-NE160-1753

- UPC #:

- 88563023802

- Part #:

- 194R-NE160-1753

- New/Surplus $ 623

- Refurb. Price $436 Save up to $ 187

- Repair Price $312 Save up to $ 311

-

Allen-Bradley

Allen-Bradley194R-NE160-1754: Allen-Bradley Disconnect non-fused IEC 4 poles 160A

- Model #:

- 194R-NE160-1754

- UPC #:

- 88563023803

- Part #:

- 194R-NE160-1754

- New/Surplus $ 746

- Refurb. Price $522 Save up to $ 224

- Repair Price $373 Save up to $ 373

-

Allen-Bradley

Allen-Bradley194R-NE125-1753: Allen-Bradley Disconnect non-fused IEC 3 poles 125A

- Model #:

- 194R-NE125-1753

- UPC #:

- 88563023800

- Part #:

- 194R-NE125-1753

- New/Surplus $ 540

- Refurb. Price $378 Save up to $ 162

- Repair Price $270 Save up to $ 270

-

Allen-Bradley

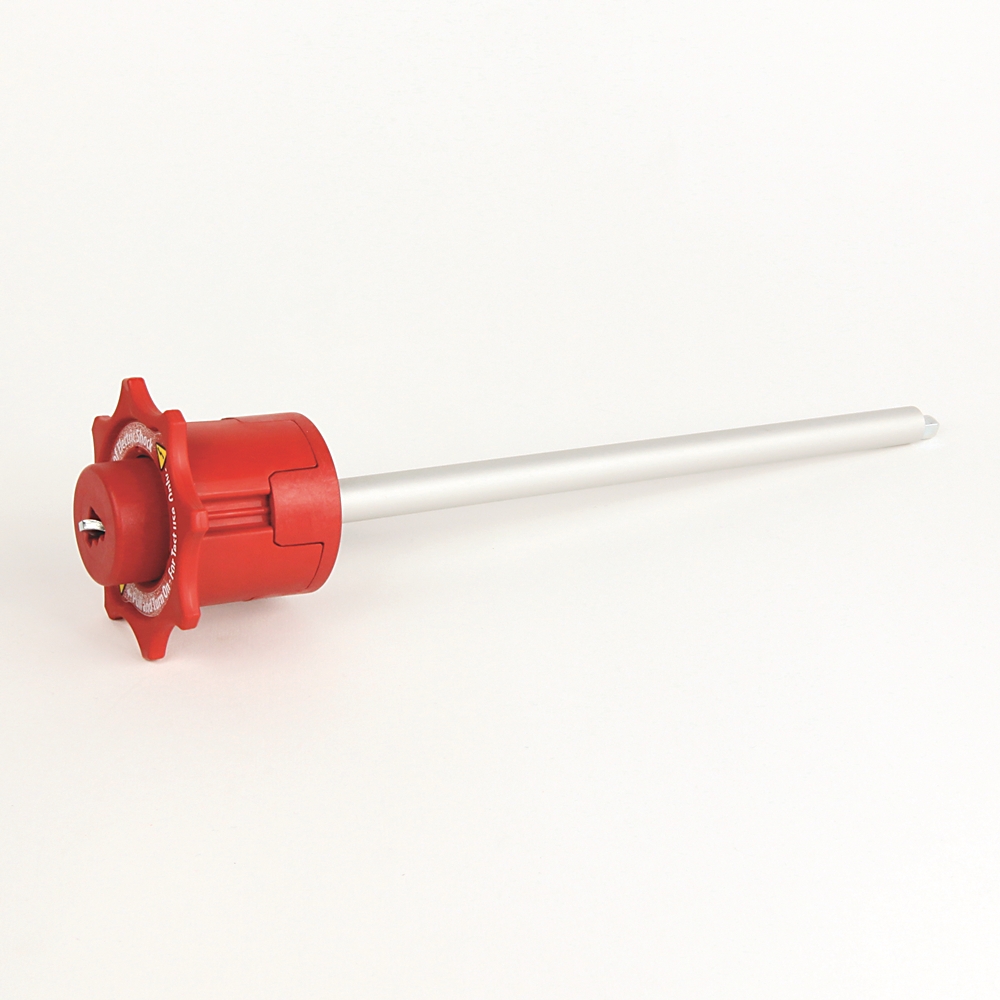

Allen-Bradley194R-N2: Allen-Bradley 194R Internal Operating Handle

- Model #:

- 194R-N2

- UPC #:

- 88563024339

- Part #:

- 194R-N2

- New/Surplus $ 94

- Refurb. Price $66 Save up to $ 28

- Repair Price $47 Save up to $ 47

-

Allen-Bradley

Allen-Bradley194R-N30-1753: Allen-Bradley Non-Fused 194R Disconnect Switch

- Model #:

- 194R-N30-1753

- UPC #:

- 78118076130

- Part #:

- 194R-N30-1753

- New/Surplus $ 306

- Refurb. Price $214 Save up to $ 92

- Repair Price $153 Save up to $ 153

-

Allen-Bradley

Allen-Bradley194R-N1: Allen-Bradley 194R Internal Operating Handle

- Model #:

- 194R-N1

- UPC #:

- 88563024338

- Part #:

- 194R-N1

- New/Surplus $ 88

- Refurb. Price $62 Save up to $ 26

- Repair Price $44 Save up to $ 44

Types of Disconnect Switches

There are two main types of disconnect switches — electrical disconnect switches and battery switches:

- – Electrical disconnect switch: The International Electrotechnical Commission (IEC) and the National Electrical Manufacturers Association (NEMA) maintain the standard for these switches to protect personnel from exposure to dangerous power levels. Manufacturers typically place these switches in machines with industrial electric motors like forklifts and household electrical appliances like air conditioners.

- – Battery disconnect switch: The user installs this knife switch over the positive or negative terminal to prevent the battery from draining when the vehicle sits unused for long periods. There is also the option to have a battery disconnect switch with a removable knob to prevent auto theft when a car is sitting in a public garage.

There are also two types of fuse switch designs, including fusible and non-fusible. The fusible switch design protects workers against dangers like short-circuiting and overcurrent. The non-fusible disconnect switch only focuses on turning electrical flow on or off without these added protections. That’s why manufacturers recommend contractors only place non-fusible disconnect switches on a system that has a dedicated fuse upstream or a fault current that totals less than 5kA.

Disconnect Switch Strengths

Disconnect switches also usually come in general and heavy-duty configurations:

- – Light switch: This switch usually works for motor circuits and service entrances in residential and commercial settings as well as some low-power industrial applications.

- – Heavy-duty switch: These switches provide peace of mind when service continuity is vital for an industrial application. They can generally handle 30-1200A and feature a rotary blade mechanism with visible double break.

Request a Quote Today

Looking for a replacement disconnect switch or a repair service to partner with your company? Global Electronic Services has highly trained technicians with the most up-to-date certifications, including certifications in EASA, ISCET, IPC and MIL-SPEC standards as well as factory-authorized training. You can also browse our wide selection of disconnect switches above to find an option that meets your company’s operational needs.

Reach out to us by phone to speak with a friendly representative at 877-249-1701 or fill out a contact form online to receive a quote and have your questions answered.