Don’t Skip It, Before You Ship It – 5 Steps To Take Before Sending A Repair

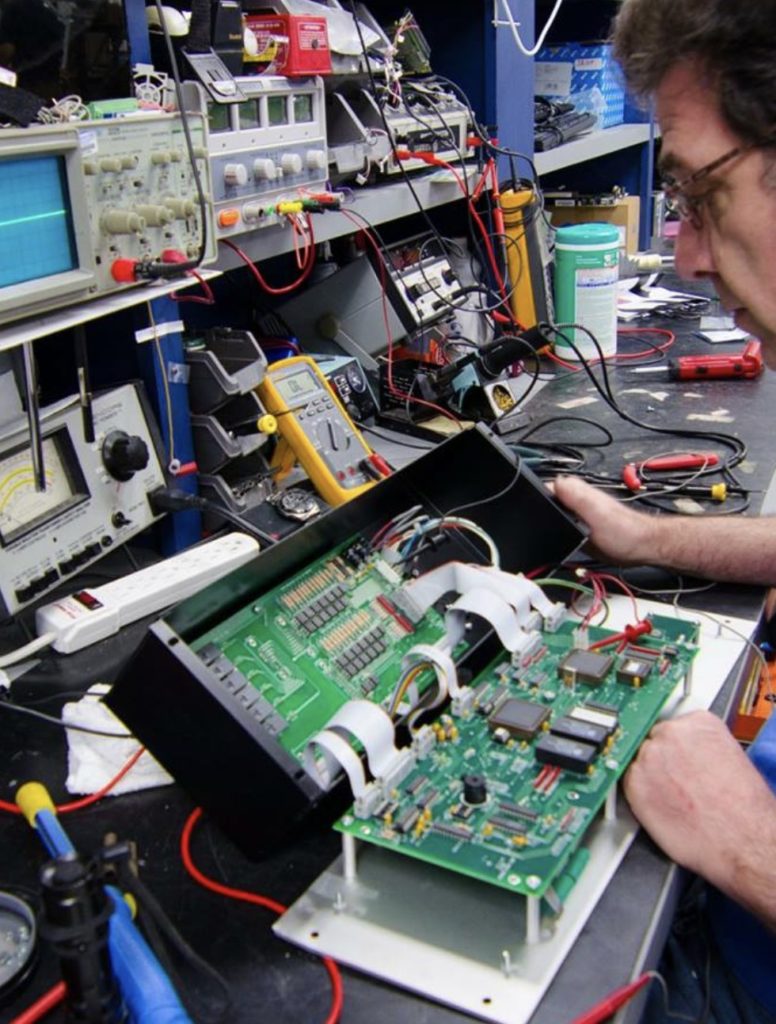

You have a machine down and are now in a mayday situation. Production has stopped, orders will pile up and the clock has just begun ticking. After some intense troubleshooting, you have identified the failed unit and are now ready to rush that thing into the service center just as fast as it will go. The first impulse will be to uninstall it as quickly as possible and throw it in a box to send out for repair. While we appreciate the business, we also want our customers to have as much success as possible when getting their machines back up and running. Here are 5 useful tips when preparing a unit to be sent in for service.

Step 1. Gather Information

The more information we can receive on the failure or source of the failure the better! It helps a technician a tremendous amount to know what the customer is seeing on their end to quickly identify and repair a problem. Also, be sure to interview all employees that may have been around when the failure on the machine occurred. Often times the only person involved with gathering information on the repair will be the maintenance supervisor (who only has knowledge after the fact, when he was called to the machine), when in reality, the machine operator who saw the failure firsthand could have much more useful information on the failure. Just remember to let everyone know you are not looking for someone to blame, but simply trying to prevent a future problem.

Step 2. Look for Related Failures

After identifying the failure, do not narrow your vision to just that piece of the puzzle. Machines are made up of many interconnected components and when one fails, often the real cause of the failure is overlooked. For example, when a drive fails, be sure to check the motor for any issues (or better yet send it in for preventative maintenance and to have them both checked together). When you see sparking on the input side of a device, perhaps look for a failed power supply on the same circuit. Taking this step will save you from experiencing a repeat failure. Nothing is more frustrating than having a unit repaired only to have to send it again because the root cause of the failure was on the machine-side and was not properly addressed.

Step 3. Document and Record

Whether you have only two wires to unhook or twelve hundred, document everything. When you uninstall the damaged unit, label your wires. Be sure what you are using is sturdy and will remain affixed. Do not use tape that will slip off with grease or dust. Also, take before, during and after pictures of the operation. These pictures can save you from a tremendous headache later on. Also, when possible, make sure to save any parameters and record any settings before the unit has been taken out of service.

Step 4. Communicate with the Service Center

The most important step you can take is giving the repair technicians the most complete information on the failure your device is seeing. Towards this we suggest two avenues of communication. First, call in and get an RMA. Customer service will be able to transfer any information they receive into the system electronically and this data will follow the unit wherever it goes once it is received into our database. This is a great way for you to let us know the repair is coming so we can prepare accordingly. Second, affix this same information on a note or tag to the unit itself and be sure to put the RMA number on your packing slip.

Step 5: Package Accordingly

Make sure you package the unit correctly! Nothing is worse than taking what could have been a quick fix and increasing the lead time because the unit was further damaged in shipping! This is what seems like a no-brainer, but often times gets overlooked. The crew down in shipping may only be using packing the products you produce, and may not have the knowledge or materials to ship the repair in the safest way. Be sure the unit has at least 2-4 inches of packing protection on all sides, and that the size and weight rating of the box you are using matches the demand of what you are shipping. If in doubt, call us! We can help. We will even send you the packing material you need, if you don’t have any available.

It is a simple fact that having your electronics, hydraulics and motors repaired will prevent downtime. And when it comes to preventing downtime, the benefit of sending in a unit the correct way cannot be understated. Just a few minutes of preparation, a little care, and some good communication, will insure that your machine will be up and running in the fastest time possible. Of course we all know that things happen and in the event that you can’t take these steps our experienced group of technicians will be able to get your unit repaired and sent back to you quickly!

Please share your comments or questions with us below and be sure to visit gesrepair.com or call us at 1-877-249-1701 to learn more about our repair services. We’re proud to offer Complete Repair and Maintenance on all types of Industrial Electronics, Servo Motors, AC and DC Motors, Hydraulics and Pneumatics. Please subscribe to our Blog and our YouTube page and Like Us on Facebook! Thank you!