Port Congestion Putting Strain on Manufacturers

Supply chains problems persist in the wake of the pandemic, and the resulting pain points are becoming clearer. One of the most significant and consistent disruptors is the unrelenting congestion at ports around the world. Import-export is now a waiting game, and ships are spending days — or even weeks — on standby for port admission and unloading.

Shipping congestion is sending ripples of frustration throughout the global economy, and they’re hitting the manufacturing industry with particular force. Domestic producers anxiously await raw materials — stuck fast between surging demand and dwindling inventory.

Port congestion reaches record levels

Port congestion levels are hitting historic highs, and the Port of Los Angeles — the largest in North America — is a case in point. As of October 2021, the Port of Los Angeles has a backlog of approximately 200,000 shipping containers at anchor. Dockworkers are purportedly working at breakneck speeds to keep ships moving through the port. And according to executive director Gene Seroka, “We had 25% of all cargo on our dock sitting here for 13 days or longer [and] that’s been cut in just about half over the last week.”

But delays look likely to continue despite these efforts. Because the biggest challenge for ports remains their limited workforce — and not enough hours in the day.

A look at Biden’s 24/7 port plan

President Biden’s plan for resolving port congesting keeps the Ports of Los Angeles and Long Beach running 24/7 and gives workers “more hours in the day” to process the unprecedented — and growing — backlog of ships. Big name corporations are already pledging their support. To aid in efforts to clear ports around-the-clock, companies, such as FedEx, Walmart, and Target, are stepping up their after-hours operations.

While many have expressed hope in response to the president’s plan, others are skeptical. Kenny Vieth, president and senior analyst for ACT Research spoke recently about other port-related issues: “Port throughput is not just taking containers off steamships, but having the capacity in the yard to position those containers, the chassis to put the containers on, the drivers to take the freight from the ports, and capacity in the rail network to facilitate the hoped-for acceleration in port throughput,” Vieth said. “While the President’s recognition of the situation is welcome, and will undoubtedly help at the margin, this effort resembles squeezing a balloon: The problem appears likely to be pushed to the next mode with insufficient capacity.”

Manufacturers are under strain — and getting worried

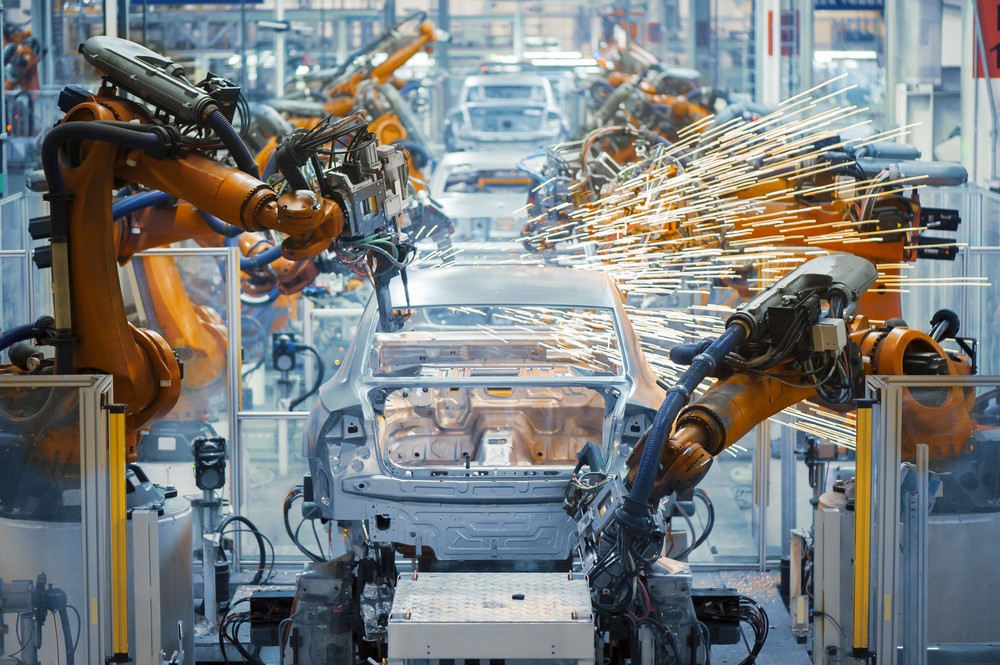

Manufacturers across all sectors are feeling the pressure of port congestion. They’re struggling to get supplies and facilitate their own import-export operations. Tesla is having problems keeping its production schedules intact, and they’re just one of many companies seeking alternative production and shipping options. Like many producers in a similar position, they’re concerned —and working under the assumption — that the global effect of port congestion will only continue to deteriorate.

Is there any relief on the horizon?

Round-the-clock port access can help alleviate some of the current tensions at the country’s busiest ports, but it’s only a stopgap measure. Bigger problems arise from the complexities of intermodal transport — finding enough truckers to clear stockyards of containers. Port infrastructure also plays a role. Many ports are aging or closed and thus unable to lend support. Taken together, these individually large problems add up to a fundamental need to reassess the structure and intricacies of domestic supply chains. Alleviating port congestion will undoubtedly help, but it’s only the first step on the long road to permanent systemic improvement.