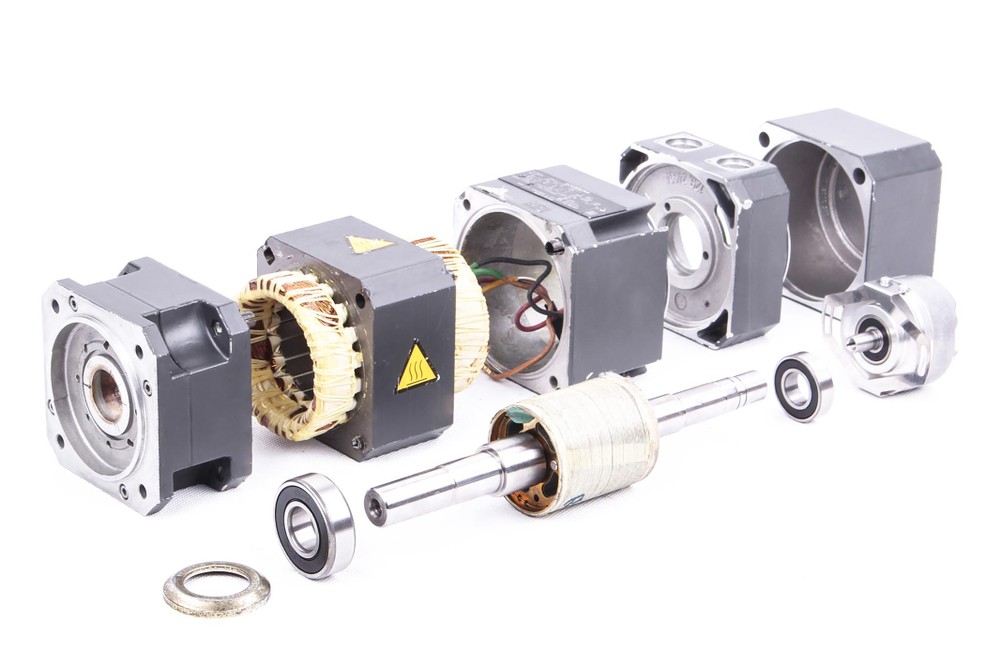

Parts Breakdown: Get To Know Your Servo Motor

From computer numerical control (CNC) machines to assembly line equipment, servo motors are the unsung heroes of factory automation. Though tiny, these devices are prevalent throughout the manufacturing environment — busily translating electrical signals into mechanical function — but the rigorous use they endure puts them at high risk for malfunction. Damaged servo motors are often to blame for equipment inefficiency.

To service a servo motor, maintenance technicians need a clear understanding of its individual components. From troubleshooting to repair, familiarity is fundamental to a successful service approach. Servo motors truly are the sum of their parts.

Here’s a breakdown of the components present in every servo motor:

- Housing. The housing protects a servo motor’s inner components from potential contaminants. It’s made of coated aluminum and designed to be taken apart and put back together quickly.

- Motor shaft. Usually made of cold- or hot-rolled steel, the motor shaft works much like a prime mover. It features a gearbox or belt-and-pulley system that sends energy to boost the motor’s torque while reducing its speed.

- Bearings. Bearings are the workhorses of a servo motor. They are constantly vibrating and moving, which causes plenty of wear and tear. Even slightly worn bearings can cause problems — from feedback errors to high temperatures — when the motor is running. It’s important to regularly check and replace bearings to prevent these symptoms.

- Rotor. Typically attached to the motor shaft, the rotor is the moving part of a servo motor. It rotates in the right direction, with the specified voltage, until the error is zero.

- Stator. Part of a servo motor’s stationary components, the stator creates a rotating magnetic field to efficiently generate torque. It’s composed of 12 individually wrapped winding segments joined by a copper wire.

- Brake. A servo motor’s brake holds objects in place when a machine is powered down or an emergency stop is triggered.

- Snap ring. Snap rings soften the impact of an undesired force to prevent damage to the motor and keep the shaft in position.

- O-ring. Each servo motor contains several O-rings — seals made from plastic polymers — to keep fluid from entering the system.

- Bearing keeper. This movable plate holds bearings and prevents them from slipping out of place by the pulley end of the motor.

- Encoder. A small, lightweight encoder communicates the motor’s speed and direction to the drive, which allows the operator to monitor and change parameters in an instant.

Servo motors are more complex than they look, which makes a trained specialist necessary for effective monitoring and maintenance. An expert partner will help you troubleshoot servo motor issues, determine the components needed, and suggest upgrades to make your factory operations more efficient.