New Bearing Sensor Technology Heralds the Future of Condition Monitoring

It seems as though there’s a new gadget or piece of industrial tech released every day. As the industrial internet of things (IIoT) expands, it’s these technologies that drive it. And now, they’re becoming even more specialized. Recently, global technology leader ABB released new smart sensor tech, designed for condition monitoring of manufacturing bearings. It’s an early sign of more specialized IIoT equipment to come.

Smarter tech for better insights

For mounted bearings, condition monitoring is critical. Unfortunately, it’s often overlooked. Bearings may be hard to reach for testing or only tested during routine servicing. This is a recipe for failure and one ABB recognizes.

The ABB Ability™ Smart Sensor provides an overall health check of mounted bearings, with alerting capabilities for any anomalies detected, such as heat or vibration. More than reporting potential problems, the smart sensor allows maintenance techs to monitor equipment remotely. When configured to the manufacturing network, ABB’s sensor communicates wirelessly with a smartphone, tablet, or laptop.

The most amazing thing about ABB’s smart sensor is its out-of-the-box readiness. It’s installed in minutes (no wiring required), with configuration taking only minutes more. Manufacturers gain access to a self-contained, smart, integrated sensor in far less time than a manual evaluation of the bearing would take.

Developing an ecosystem

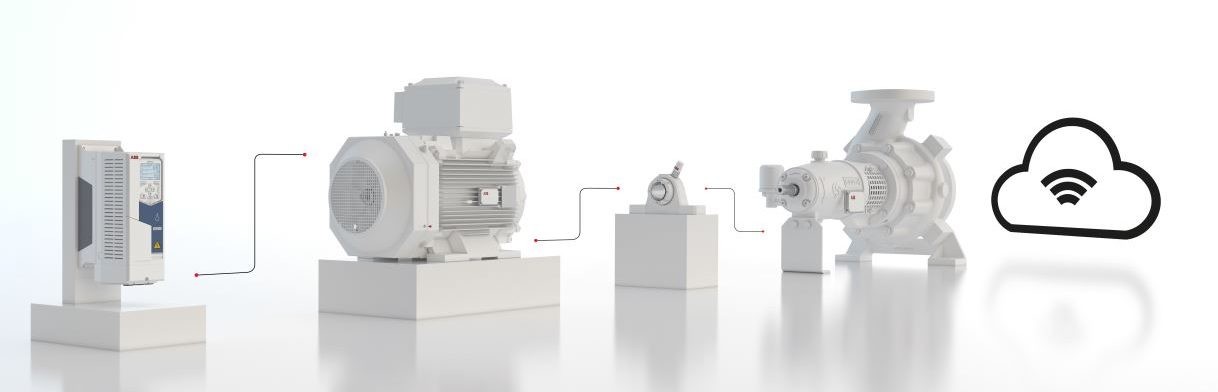

The ABB Ability™ Smart Sensor isn’t just a standalone product: It’s part of the company’s Ability Digital Powertrain, an early leader in end-to-end manufacturing monitoring systems. Alongside products such as the ABB Ability™ Smart Sensor for motors and the ABB Ability™ Smart Sensor for pumps, ABB’s focus on the future is evident.

In producing sensors for each unique type of manufacturing equipment, ABB is catering to the concerns of factory operators. Where failures in bearings, motors, and pumps might otherwise occur, these smart sensors enable techs to stay one step ahead. The result is maintenance instead of repair.

This ecosystem is one manufacturers are desperately seeking. As many struggle to put the IIoT into practical use, bearing, motor, and pump sensors fill an obvious need.

Paving the way for better condition monitoring

ABB’s focus on anticipating equipment breakdowns isn’t just producing great products: It’s drawing attention to a unique segment of the IIoT. Condition monitoring is an extremely important part of delivering preventive maintenance and preventing downtime. It’s also a simple, practical, cost-efficient entry point into Industry 4.0 and one manufacturers can understand.

Condition monitoring is traditionally inefficient. For bearings, a maintenance worker needs to manually check each bearing for suspect issues, using different equipment to monitor for vibration, temperature, and other variables. This occurs while bearings are in operation, also introducing safety concerns. It’s a generally cumbersome process that, while important, is often overlooked. If the bearing is in good standing, the time spent checking it could’ve been better spent elsewhere.

Adopting smart bearing sensors and other condition monitoring tech from companies like ABB improves the efficiency of the process by removing manual labor. It’s only when problems arise that a tech has to act.

The best is yet to come

This technology is among the first of many more iterations to come. As condition monitoring distinguishes itself as a critical application for the IIoT, demand from manufacturers will likely fuel other companies to create products and ecosystems in the spirit of preventive, proactive maintenance.

Do your bearings need to be replaced or serviced? You can always count on the professionals at Global Electronic Services. Contact us for all your industrial electronic, servo motor, AC and DC motor, hydraulic, and pneumatic needs — and don’t forget to like and follow us on Facebook!