Why Do Some Manufacturers Prohibit Device Repair?

What if manufacturing machines and vehicles were like devices such as smartphones and tablets in that it was common practice to simply throw them away when they broke down or when the next model came out? That would make for expensive replacements all too often and would add quite a bit of excess waste material to landfills. Plus, mechanics and repair experts could lose their livelihoods. Lucky for manufacturers, repair services can often solve these problems and more.

Repair, recycle, or reduce to waste

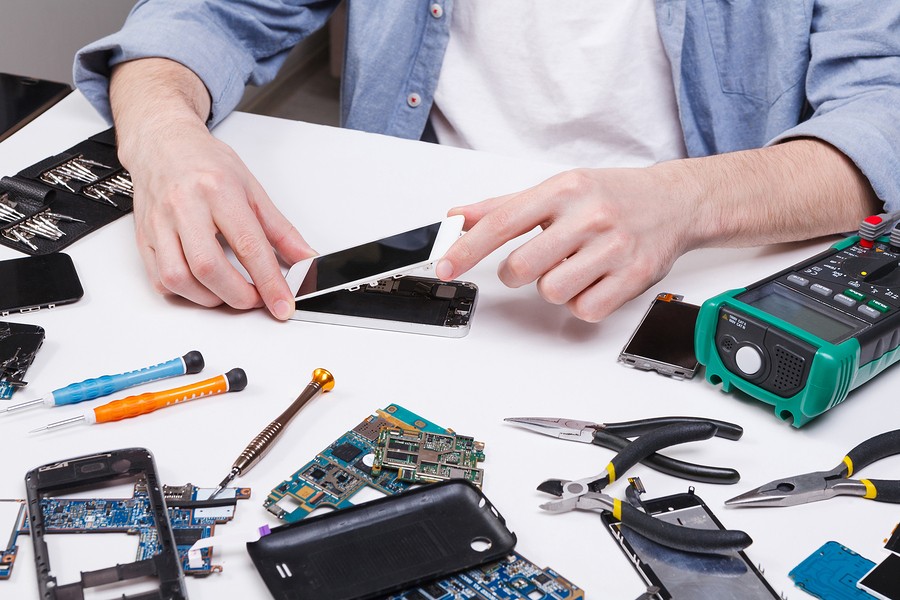

Manufacturing equipment repair requires specially trained professionals just as vehicles require mechanics. But many equipment and vehicle manufacturers allow repairs — so why not device manufacturers?

Manufacturing equipment repair requires specially trained professionals just as vehicles require mechanics. But many equipment and vehicle manufacturers allow repairs — so why not device manufacturers?

Trashed devices are equal to 22-55 million tons of waste per year. Some of these materials can be recycled, but many devices also contain harmful substances like mercury and lead, which go straight to landfills. Why? Manufacturers who own the rights to these products say their patents and copyrights cover the repair process and system knowledge necessary for repairs as well, often leaving those with broken devices without options.

Manufacturing woes

The problem, however, isn’t limited to smart consumer devices. It also includes software and other proprietary systems installed in certain machines from farms to factory floors. Repairs for these machines can often only be left to original equipment manufacturers who own the rights to repairs and may charge a premium to do so — and, to top it off, those who use these devices in their fields and plants may not be able to easily access repair facilities because of distance or other factors.

Without access to affordable, convenient repairs, machine owners may have to shut down operations, thereby costing them more money in downtime as they wait for repair personnel or send their machines off for fixes. And when the machine OEMs must continue pushing forward to create the most innovative new offerings, they can’t always train their mechanics on outdated machines or even stock parts for them. This means machines naturally become obsolete. And without repair options, manufacturers are forced to buy new, which then forces their broken-down machines into landfills.

Add to that the need for manufacturers to ensure their entire systems work with the new machines they’re forced to buy and expenses rise again.

Positive changes

Luckily, the advent of 3-D printing is solving many issues surrounding parts creation for outdated machines as they can be remade without mass production. And how-to videos and tutorials are available online for many to do minor in-shop repairs.

Plus, certain states are pushing OEMs to make parts, tools, and more available to individuals and repair companies, allowing for longer device and machine life spans. Some repair companies can even work with manufacturers with broken machines to deliver temporary replacements during repair, much like vehicle owners riding in courtesy shuttles while mechanics are repairing their vehicles and cellular companies offering loaner phones while their personnel fix devices.

The green manufacturing movement is further encouraging OEMs to allow independent repairs and materials recycling. So, rather than harmful materials ending up in landfills, those with the know-how can repair if possible — and otherwise know what they can recycle and how to do so — making the industry even more Earth-friendly.

Have a repair you can’t complete in-house? Call on the experts at Global Electronic Services. Why choose us? We can come to you or you can send your machines to us with a turnaround time of five days or less. Plus, we offer free 24- to 48-hour rush service so you can get your plant back in action quicker than ever — and we return your equipment to you fully load tested with an 18-month in-service warranty. If we can’t repair your machine, we can often offer a refurbished unit or alternative. Contact us today for all your industrial electronic, servo motor, AC and DC motor, hydraulic, and pneumatic needs — and don’t forget to like and follow us on Facebook!

Have a repair you can’t complete in-house? Call on the experts at Global Electronic Services. Why choose us? We can come to you or you can send your machines to us with a turnaround time of five days or less. Plus, we offer free 24- to 48-hour rush service so you can get your plant back in action quicker than ever — and we return your equipment to you fully load tested with an 18-month in-service warranty. If we can’t repair your machine, we can often offer a refurbished unit or alternative. Contact us today for all your industrial electronic, servo motor, AC and DC motor, hydraulic, and pneumatic needs — and don’t forget to like and follow us on Facebook!