What Makes Spindle Motor Repair So Tricky?

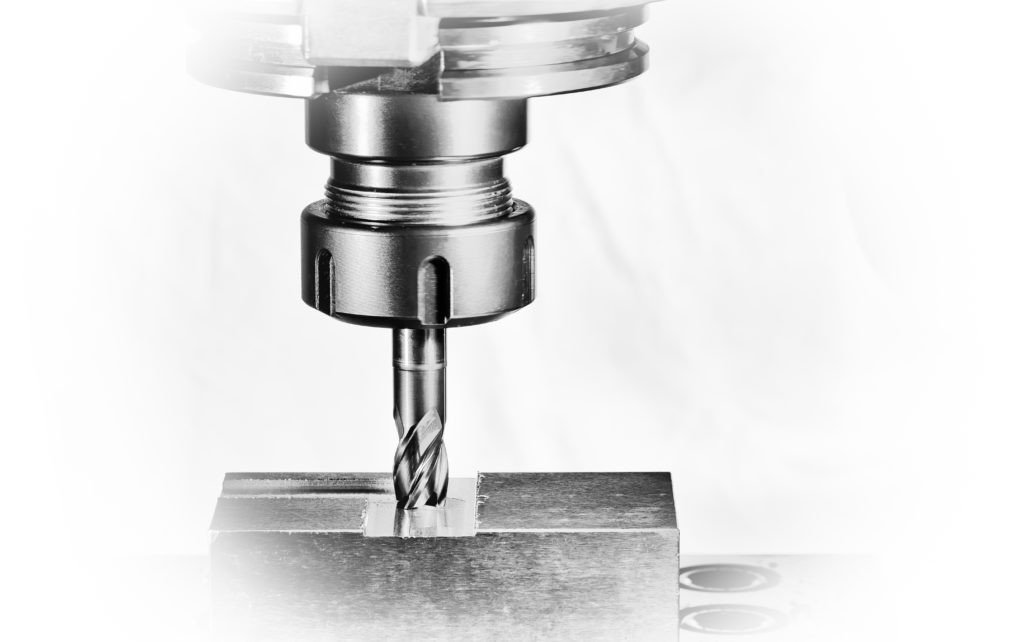

For those unfamiliar with what a spindle motor is, it is a motor that is designed to rotate at high speeds, most commonly used in applications such as CNC milling machines. Like all motors, spindle motors can and will break suffering many of the same failure modes as other types of motors. But repairing a spindle motor can be tricky, much of the time requiring special tools and know-how. What are some aspects of spindle motor repair that makes it so difficult?

High Speed Considerations

By their very nature, spindle motors are meant to rotate at very high speeds. As such, many of the parts within the motor must be made both more durable and designed within very tight tolerances. For example, standard bearings will not work within a spindle motor and will heat up quickly. Bearings made for high speed have special materials and lubricant to withstand the speeds at which these motors run -and are very costly. These parts must be installed using special tooling and if mistakes are made they are expensive.

Balancing

While proper rotor balancing is important for any motor application, on a spindle it is particularly so. Imbalances in rotating apparatus will always develop problems eventually, and the faster the rotation, the sooner the failure will develop. The vibration caused by rotor imbalance can cause damage to tooling, overheat the motor, or damage the spindle entirely. This is why after every repair it is important to balance the rotor of the spindle within very tight specifications.

Precision Machining

Many spindle motor repairs will involve correcting mechanical damage of some form or another. Whether it be correcting a worn bearing journal, cutting keyways, or repairing tool holder damage machine work is often necessary to complete these repairs. Spindle motors in particular are very unforgiving when it comes to this type of work because if it is done wrong, failures will show up quickly due to the motor running at high speeds and under load. All machine work done must be performed with careful measurements and with absolute motor balance in mind.

If you are in need of any type of Spindle Motor repair, the experts at Global Electronic Services are here to help! Be sure to visit us online at gesrepair.com or call us at 1-877-249-1701 to learn more about our services. We’re proud to offer Surplus, Complete Repair and Maintenance on all types of Industrial Electronics, Servo Motors, AC and DC Motors, Hydraulics and Pneumatics. Please subscribe to our YouTube page and Like Us on Facebook! Thank you!