Industrial Robot Applications

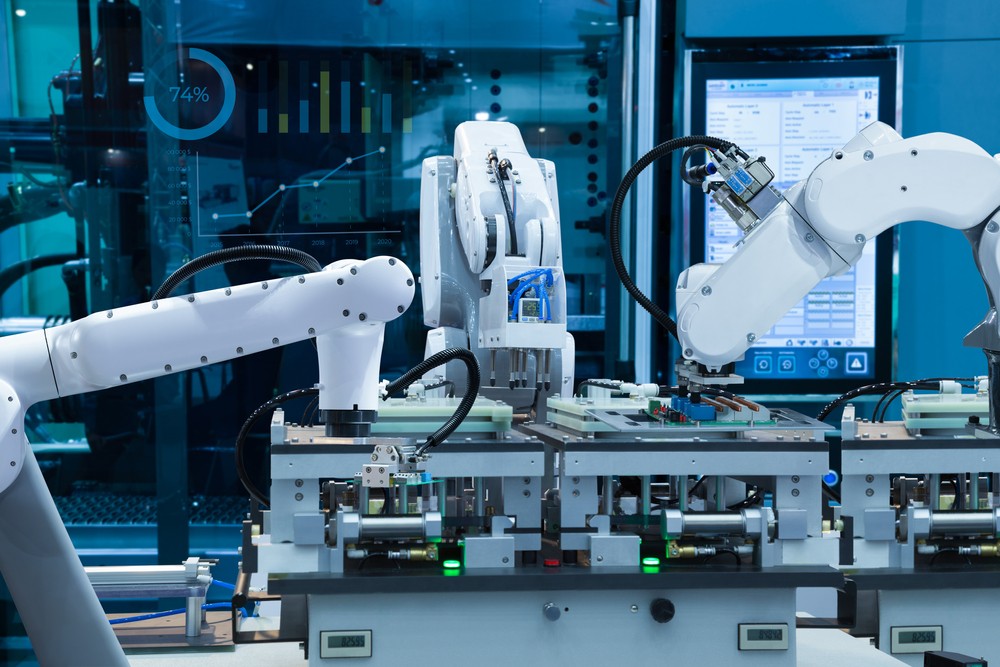

Through their continuous precision and high speed, industrial robots allow the manufacturing sector to effectively accomplish tasks with minimal error. They can also promote workplace safety by eliminating the need for human workers to perform dangerous or tedious jobs. You can take advantage of this new and innovative technology by investing in industrial robots for these common applications.

Welding

Since its introduction in the 1980s, robotic welding has become one of the most popular applications for industrial robots. Since vehicle assembly requires such a high volume of welds, robotic welding drastically decreases the hours needed to produce a car.

Two of the most common industrial robot applications are arc welding and spot welding. When used for arc welding, industrial robots eliminate the need for workers to risk inhaling hazardous fumes or being burned. Spot welding uses a current to join two metal pieces at speeds as fast as 10 milliseconds — robots offer enhanced precision in this task.

Material Handling

Minimize the risk of worker injury by having an industrial robot move, transfer and pick products of any weight. Material handling robots can automatically move and choose products and parts for transfer from one piece of equipment to another. Introducing material handling robots to the workplace can make your work environment safer while also reducing the direct labor cost associated with manually transferring and selecting products and equipment.

Machine Tending

Ramp up productivity and decrease production time by using industrial robotic machine tending. Machine tending tends to be tedious, dull and dangerous work that requires a high level of attention to detail and consistency that is difficult for humans to achieve. Through industrial robotic machine tending, the consistency and productivity of product tending will increase while your facility will see fewer worker injuries.

Painting

Completing painting tasks with industrial robots improves automotive paint jobs by giving them an even, smooth and consistent coat of paint all around. Machine painting was first popularized with hydraulic robots but is now most frequently used with electronic versions. The use of painting robots minimizes the time workers spend around potentially dangerous fumes while providing a more consistent application around the entire vehicle.

Gluing, Spraying and Sealing

In addition to painting, robotics has helped the manufacturing industry glue, seal and spray products more effectively. Electrically driven thermal sprayers can apply heat-resistant coatings more evenly, while mechanical bonding and sealing technology can bond large and small items alike. Through using a robotic gluing, spraying or sealing machine, adhesives and sealers are used more effectively and there’s less product waste.

Other Applications for Industrial Robots

Global Electronic Services is a worldwide leader in industrial robotics and will provide your business with premium machines and exceptional customer service. We can deliver advanced technology to further your company’s goals, as well as repair and replacement parts for industrial robots used in any application.

All products come with an 18-month warranty, in-house repair services, free evaluations and load testing. To learn more, call 877-249-1701 or request a free online quote today.