In the Wake of COVID-19, the US Must Enhance Domestic Medical Supply Manufacturing

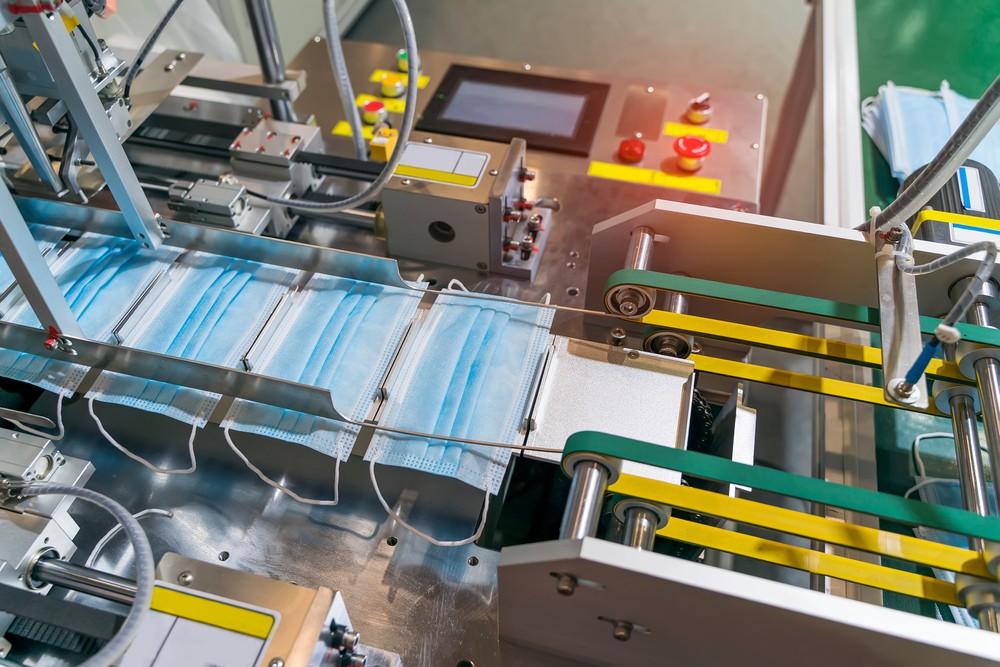

It was a short 12 months ago when the full force of COVID-19 was bearing down on the world. Before any prospect of a vaccine, the focus was on vital medical supply: ventilators, tests, N95 masks, gloves, and other essential personal protective equipment (PPE). There wasn’t enough to go around, and procuring more was virtually impossible due to global supply chain disruption. Now, amidst the full swing of mass vaccinations, it’s important not to forget this lesson. The United States needs to ramp up domestic manufacturing of vital medical supplies.

Manufacturing of vaccine dispensing products

While PPE isn’t in the dire supply it was in the early days of the pandemic, the focus has shifted to other essential medical supplies: specifically, items needed to administer the vaccine, including hypodermic needles and latex gloves. The problem is, many of these products are manufactured only in Southeast Asia. Top Glove, for example, is the world’s largest producer of latex gloves, headquartered in Malaysia.

The big concern during the pandemic was the delay in product shipment from other countries to the United States. Even as supply chains heal, other problems have bubbled to the surface. Cost, for example, isn’t as low as it was pre-pandemic, and global demand remains at an all-time high. With the continued demand for these items, the United States needs to start producing them domestically, to avert new and known supply chain issues and to rebuild the Strategic National Stockpile.

Streamlining the supply chain

Interest in bringing medical supply manufacturing back to the United States began largely due to the pandemic, but China’s rising labor costs are a factor as well. Looking forward, American supply chain reshoring becomes less a matter of cost and more an urgent convenience — especially in the event of another national health emergency.

Domestic production of critical medical goods isn’t just an opportunity; it’s a necessity. Stories of critical care nurses fashioning makeshift PPE from household goods illustrates this better than anything. Consolidating supply chains and bringing them closer to home is the biggest and most essential step to avoiding another #GetMePPE situation in the future.

The White House’s role

During the Donald Trump presidency, Peter Navarro served as the President’s trade advisor and oversaw deals with American companies in an effort to increase medical supply manufacturing in the country. Many of the deals took place as part of the Defense Production Act.

Navarro established deals with several companies to help kick-start domestic medical supply manufacturing, including Eastman Kodak, AirBoss, and Phlow: Eastman Kodak for the production of generic drugs; AirBoss to manufacture respirators; and Phlow to produce pharmaceutical ingredients. Ultimately, these deals fell far short of kick-starting domestic production of medical supplies — and some, like the Eastman Kodak deal, faced criticism.

Demand for medical supply still lingers

COVID-19 may soon be behind us, but the need for vital medical supplies will continue to increase. Now, more than ever, it’s important to bring medical supply manufacturing back to the United States. If we’ve learned anything over the past year, it’s the importance of having medical supplies available and attainable by those on the front lines, who need it most. That’s a difficult pill to swallow when you’re waiting on needles, rubber gloves, face masks, and other essential supplies en route from Southeast Asia or another far corner of the world.