Identifying 1 of the Biggest Factory Wastes: Wait Time

Students of lean manufacturing practices are familiar with the seven wastes associated with industrial operations. Waste from defects, overproduction, unused talent, and extra processing are constant battles, fought and won with smart management on the factory floor. But the biggest and most prolific waste is one that’s fought at a higher level. Cutting down wait time and wasted time comes from making procedural changes.

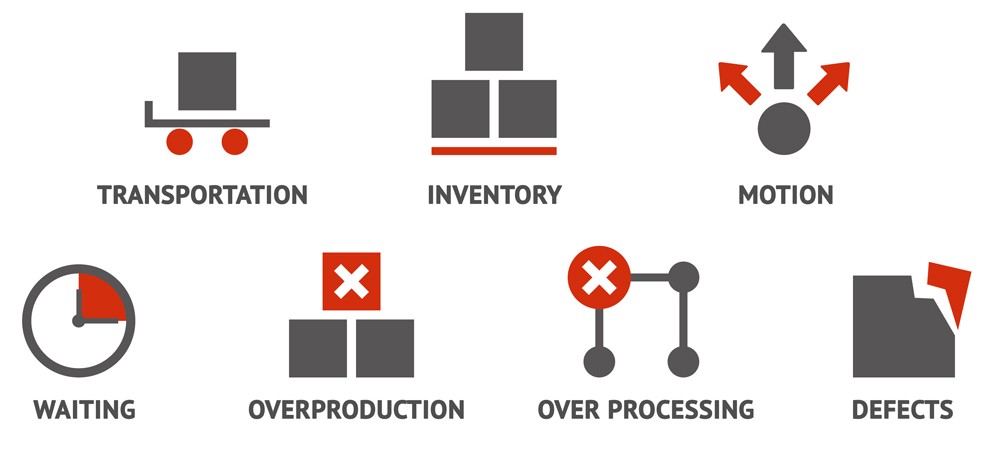

The seven wastes of lean

All waste is bad, and the mission of lean manufacturing is to eliminate them. The “mudas” as they were originally coined, include:

Transportation

Transportation- Inventory

- Motion

- Waiting

- Overproduction

- Over processing

- Defects

These wastes (TIMWOOD) are aptly identified because they have the potential to occur in any facet of manufacturing operations. You’re just as easy to waste steps between unoptimized stations as you are to create waste tying up costs in unnecessary inventory. And while each muda comes with its own negative ramifications, waiting is one of the most detrimental.

Identifying the waste of waiting

Waiting is likely the most prevalent form of waste in any factory. It’s so prevalent, in fact, that it’s likely to fly under the radar as a normalcy. No one thinks twice at an operator standing around for a few minutes waiting for their machine to warm up. Everyone expects to wait a day or two after filing an equipment requisition form. In many cases, factories will build wait into their processes in a passive form of accepting this waste.

While the waste of waiting will never be fully eradicated, it’s important to look around the factory and identify where it’s accepted.

How is waiting costing you?

Calculating the cost of wait time waste isn’t easy because it’s situation dependent. In some cases, it’s the cost of worker salary. In others, it’s lost production revenue. Examining each situation thoroughly gives a snapshot of the many ways waste is cutting into revenue:

- Any time personnel are involved, worker salary is going to waste.

- In the case of machinery downtime, production costs rise and revenue falls.

- Inefficient processes create operational waste, creating unnecessary costs.

- Unresponsive action against unforeseen issues creates untold waste and cost.

Take a simple situation, like unplanned machine downtime. Operators have to wait for repairs. Production is stunted, causing backups and waits in the workflow. This can trickle down to customers in the form of extended wait times. Every instance of wait is an instance of waste — in the form of lost revenue, incurred costs, and squandered resources.

Where the six other mudas of lean create a singular instance of waste, wait time has extrapolating wastes that quickly add up.

Seek out wait to eliminate waste

Managers observing a lean manufacturing approach need to be diligent in identifying waste. Whether it’s during a Gemba walk of your factory floor or a process engineering audit, look for wait waste. Not just where waiting is prominent, but also where it’s accepted. Instances of waiting serve as jump-off points for process improvement.