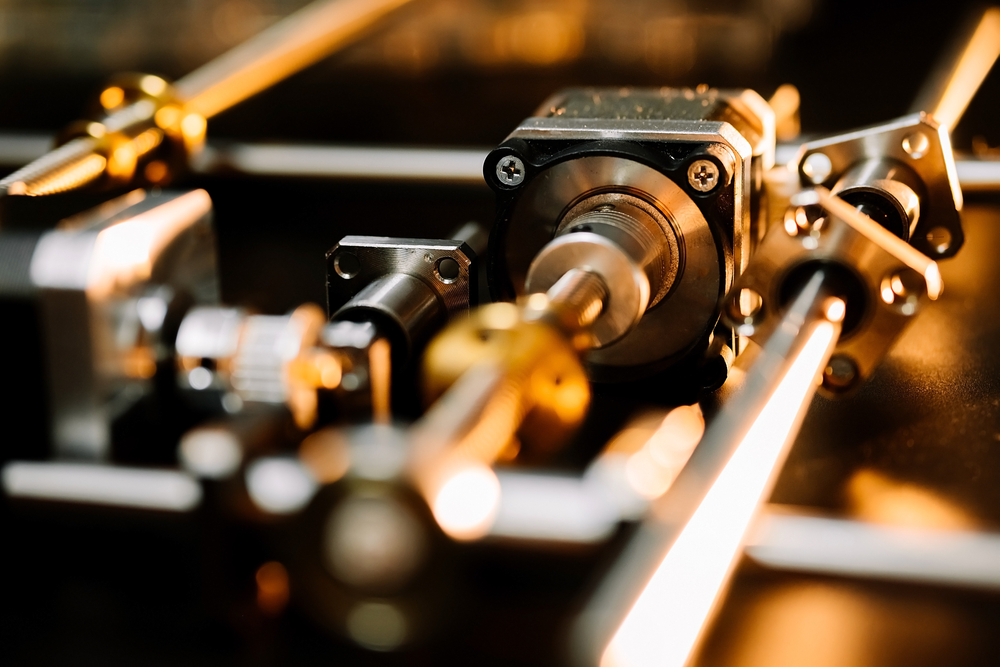

How to Solve Feedback Loop Failures in Servo Motors

When servo motors fail, it’s easy to blame the motor itself. But sometimes the motor is fine — it’s just getting bad information. Feedback loop failures often hide behind vague symptoms like drift, jitter, overshoot, and sluggish response. None of it points clearly to a specific part, and that’s what makes feedback issues so frustrating.

Unlike mechanical failures, feedback problems distort performance without tripping fault codes. They create a maddening situation where everything runs… but not quite right. Here’s a systematic approach to tracking down and fixing these elusive problems.

Step 1: Recognize the warning signs

Start by identifying the subtle symptoms that point to feedback problems rather than motor or drive failures. Position errors that increase during motion indicate your system can’t accurately track where it is, which means it also can’t correct where it’s going. Watch for commanded versus actual position curves that gradually diverge during operation.

Inconsistent homing behavior creates another major red flag. When encoders slip or lose signal during startup, home positions shift slightly from cycle to cycle, creating repeatability problems that seem random but follow a pattern. You’ll also want to monitor for oscillation near setpoints, where faulty feedback causes drives to overcorrect, creating loops of jitter or vibration.

Step 2: Test signal integrity in real time

Move beyond static testing to dynamic signal analysis during operation. Use your drive’s built-in diagnostics or an oscilloscope to compare actual versus commanded position signals in real time. If feedback is accurate, these curves should mirror each other closely — gaps or lag times indicate signal problems that won’t show up during bench testing.

Perform cable flex testing by lightly bending and flexing encoder cables while monitoring for signal consistency. Broken wires or loose crimps inside the harness often show up as intermittent dropouts during this test. Complement this with thermal imaging during runtime, since overheated encoder components create hot spots invisible to visual inspection.

Step 3: Isolate mechanical vs. electrical issues

Determine whether you’re dealing with hardware problems or signal processing issues through systematic isolation testing. Swap drive channels with a known-good axis — if the problem moves with the wiring and encoder, you’re dealing with mechanical or signal-based issues. If the problem stays with the original axis, look deeper into the drive or logic settings.

Check encoder coupling alignment and security carefully, since even the best feedback devices fail if they rotate independently from the motor shaft. Look for loose set screws, worn couplings, or misalignment that allows slippage. Don’t overlook electrical noise sources nearby, either. VFDs and high-current switching equipment can disrupt encoder signals if cables aren’t properly shielded.

Step 4: Verify system-level configuration

Examine the software and system settings that translate feedback signals into meaningful position data. Double-check software scaling and calibration settings, because sometimes the hardware works perfectly while the control system misinterprets feedback signals due to incorrect scaling factors or resolution settings.

Always test under actual load conditions rather than relying on bench testing, since feedback problems often only appear when the system operates under real-world conditions. Additionally, examine PLC processing capacity during peak operation, as overloaded controllers can introduce input lag that makes feedback appear faulty when the real problem is insufficient processing speed.

Step 5: Address root causes, not just symptoms

Focus on permanent solutions that prevent recurring problems rather than quick fixes that buy temporary relief. Replace entire cable assemblies if any damage is found — never attempt to repair encoder cables, since shielding effectiveness and signal integrity degrade rapidly once compromised.

Ensure proper grounding and shielding throughout the entire signal path, because poor grounding creates noise that corrupts feedback signals. Finally, document environmental conditions during failures, including temperature, vibration, electromagnetic interference, and contamination levels, since these factors affect feedback system reliability in ways that aren’t immediately obvious.

Precision requires perfect communication

Feedback loop failures turn precise servo systems into unpredictable machines. They rarely trigger obvious alarms and don’t leave clear diagnostic trails. Solving them requires real-time analysis, system-level thinking, and understanding how every signal contributes to overall performance.

If you’re stuck on a feedback loop failure that you just can’t seem to solve, reach out to GES. Now through the end of the month, we’re offering 10% OFF single repairs or 15% OFF 3+ repairs on safety equipment. We’ll help you set your servos right again.