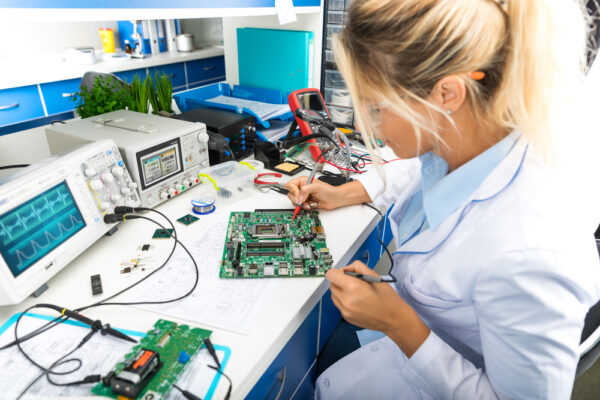

How to Repair Burnt PCB Traces (Without Replacing the Entire Board)

Wonder if a single burnt trace really means tossing the whole PCB? Know this: the board isn’t always beyond repair — even when it looks rough. A burnt PCB trace doesn’t automatically mean the whole board is toast. In many cases, the damage is isolated. With the right tools and precision techniques, you can restore function and avoid the cost of a full board replacement. Here’s how:

- Start by understanding the source of the damage: A PCB trace doesn’t burn up for no reason. Excess current, a voltage spike, poor soldering, or nearby component failure can all create a hot spot that chars or vaporizes the copper pathway. Before attempting a repair, identify and fix the root cause. Otherwise, you risk repeating the failure.

- Evaluate how much of the trace is damaged: Some traces look worse than they are. Others hide deeper damage under scorching or lifted pads. Use a multimeter to check continuity, then physically inspect the area. If the insulation layer bubbled or adjacent traces were affected, you’ll need to clear more space for a safe fix.

- Remove carbonized material and prep the surface: Any remaining char or oxidation will interfere with adhesion. Use a fiberglass pen, small file, or precision scraper to clean down to fresh copper. If the board has protective coating or solder mask, clear it away around the damaged zone to make room for repair.

- Bridge the gap with fresh copper: There are a few ways to do this. You can use copper foil tape (thin, adhesive-backed copper strips), trimming to size and laying them directly over the damaged area. Or, tinned copper braid or solid-core wire can be soldered in place to span the break. Want a more straightforward approach? Trace repair kits include pre-cut pads and traces with heat-sensitive adhesive backing. Once positioned, they’re bonded using a tacking iron.

- Add insulation or recoat the board: After the electrical connection is re-established, insulate it. Apply a small amount of epoxy or conformal coating to seal the patch. This step prevents corrosion, minimizes arcing risk, and helps mechanically reinforce the repair.

- Monitor performance post-repair: After performing repairs and reinstalling the PCB, keep a close eye under it during normal operating conditions. If you experience issues, check to make sure your repair is holding strong. If the repair is good and performance issues persist, look deeper into peripheral systems to ensure everything is operating within acceptable parameters.

Not all trace damage is easily patched with copper and solder. If multiple layers are involved or thermal stress affected surrounding components, the repair becomes more complex. In those cases, precision diagnostics and professional rework can save the board — and save money.

Now through the end of the month, GES is offering 10% OFF single repairs or 15% OFF 3+ repairs on ABB products — including PCBs. If you’re dealing with a burnt board, don’t throw it out. Instead, send it in and let us help you get your equipment back up and running again!