How to Listen for Bearing Failure Before It Happens

There’s a lot of noise to be cognizant of on the factory floor. It’s not always easy to hear the individual squeaks and scuffs of each machine, and even harder to qualify what they mean. Unfortunately, major issues like bearing failure are preceded by audible signs of trouble. Getting to know the noise of a faulty bearing setup can mean the difference between catching it early and dealing with its aftermath.

Common noises to identify bearing failure

Unexpected bearing failures can be difficult to fix and are often complicated to repair on short notice, resulting in a lot of downtime. Bearing repair is best delivered proactively, at the first sign of abnormal noise. Recognizing and qualifying that noise is paramount. It starts as part of general maintenance, and in some cases, can even be the product of just taking a moment to listen! Here’s what you might hear:

- Race noises: These noises are the product of a collision between the raceway and rolling elements of a bearing assembly. The faster the machine cycle speed, the louder and clearer it’ll get. Often, it’s the result of sub-par bearings or an ill-fitting assembly.

- Clicking: This noise occurs at low speeds and is common among large bearings. It’s the product of excessive radial load, solved by alleviating the load or applying a preload.

- Squealing or squeaking: This is — you guessed it — primarily a lubrication issue. It occurs when bearings are under-lubricated and is often resolved with the right level of lubricant or a change in lubricant viscosity.

- Cage noises: Friction between the cage and rolling elements results in cage noises. The noise changes depending on the cycle speed of the machine, from a chugging noise at low speeds to an orbital sound at higher speeds. It’s almost always a mounting error that’s easily fixed when bearings are remounted.

- Vibration: Vibration is often part of the equation with bearing assemblies and can’t be totally eliminated. That said, if the vibration turns into a violent buzz or an angry hum, it’s time to consider remounting the bearings. Check radial clearance to ensure vibration isn’t causing other damages.

- Flaw noises: If your machine sounds like a rapid-fire popgun, it’s likely a flaw you’re dealing with. Dents, rust, or warping will ping the bearing on every cycle, creating an unmistakable noise that grows in intensity with speed. Replacing the bearing is imperative.

- Contamination noises: A slow chugging noise often indicates some form of debris in the bearing assembly. Thoroughly clean the assembly and relubricate to alleviate it. If the sound persists, it may be the result of damage to the bearing, which necessitates replacement.

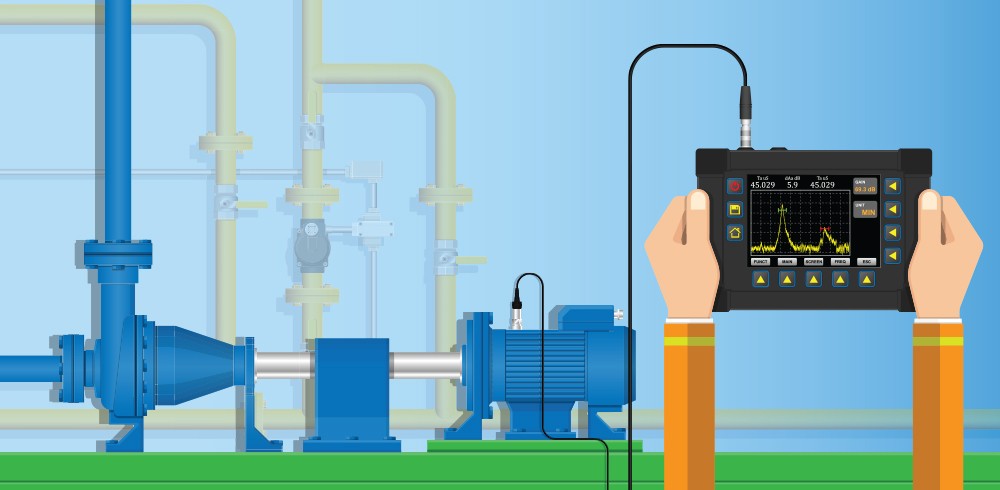

Although some of these noises occur at decibel ranges we can hear, many of them become more pronounced through the use of an ultrasound. If anything outside the normal scope of operating noise becomes prevalent, it’s wise to perform a thorough inspection — or as thorough as possible at that current time. Acting on strange bearing noises proactively is the best way to prevent what they’ll eventually become: Downtime.