How to Detect and Address Shaft Misalignment in Rotating Machinery

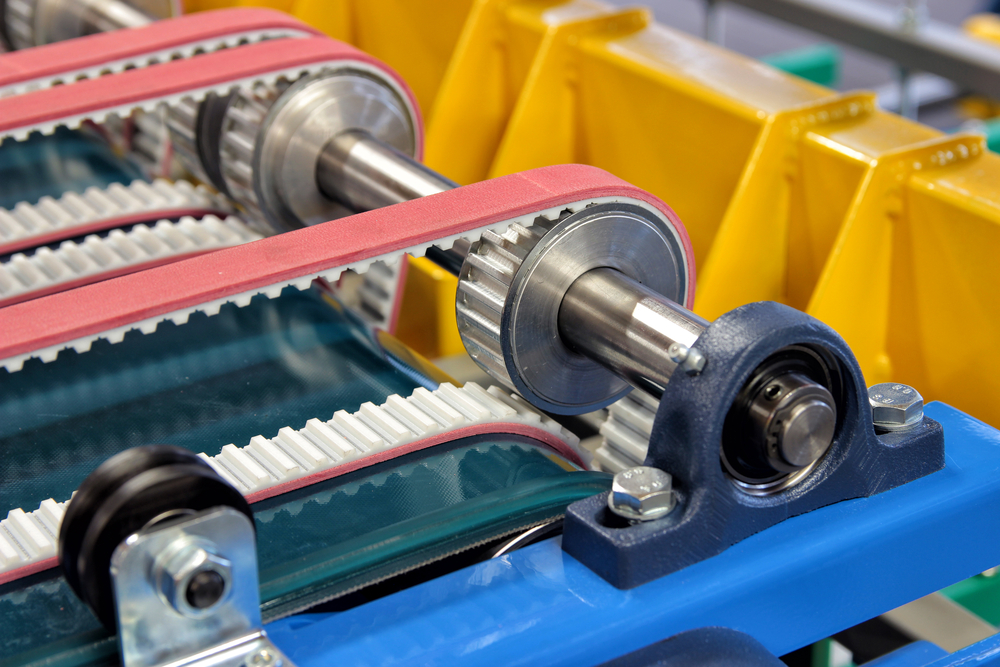

Industrial machinery is resilient, yet delicate. It can chug along for hours and hours a day, nonstop; however, at the same time, even the smallest imperfection can derail a smooth operation. Shaft misalignment is a perfect example: a seemingly minor issue that can lead to energy waste, unexpected breakdowns, and huge repair costs if left unchecked. It’s a drain on efficiency and equipment longevity if not corrected quickly.

Telltale signs of shaft misalignment

Detecting misalignment requires keen attention. Listen closely, and your equipment will reveal hidden alignment issues before they become catastrophic problems. Keep an eye out for gradual warning signs presenting themselves in the form of performance issues. Look for:

- Abnormal noises such as grinding, knocking or high-pitched whines are your first warning.

- Excessive vibration or shaking can signal underlying mechanical stress caused by shaft misalignment.

- Energy consumption spikes caused by motors that are working harder and consuming more energy.

- Accelerated component wear, causing bearings and seals to deteriorate faster than normal.

Why does shaft misalignment happen?

Misalignment doesn’t happen overnight. From a soft foot that causes mechanical stress to improper lubrication resulting in friction, shaft misalignment can creep up on you. It’s the result of cumulative, ongoing stress caused by problems that go unchecked. Some of the forces at work include:

- Thermal dynamics. As machinery generates heat, components expand and contract, creating microscopic shifts that accumulate over time. This “thermal growth” can gradually push alignment beyond acceptable tolerances.

- Installation problems. The initial mounting process sets the foundation for long-term mechanical performance. Even minor installation deviations can cascade into significant alignment challenges.

- Gradual mechanical degradation. Bearings, couplings, and mounting structures undergo continuous stress. They can experience incremental changes that ultimately compromise alignment integrity.

How do I address shaft misalignment?

Fixing shaft alignment issues is a precision endeavor that requires a high-accuracy approach. Laser tools and precision measuring devices can help identify the severity of the misalignment, and following OEM specifications is key in properly re-aligning shafts that are off kilter. After, it’s important to check the alignment again under normal operating conditions.

As is the case with any mechanical system, regular checks and early part replacements can stop bigger problems before they start. Some of the ways to tackle shaft misalignment before it becomes severe include:

- Schedule regular alignment checks. Set intervals based on your equipment’s usage and operational conditions.

- Train staff on alignment basics. Empower operators to identify small issues before they escalate.

- Invest in precision alignment tools. The cost of these tools is worth the long-term savings they create.

Partner with an expert

Dealing with shaft misalignment or persistent problems with your rotating equipment? Through December, GES is offering 15% OFF any 3 or more repairs through our Stack & Save program! Send in your equipment to make sure it gets precision alignment from Manufacturing’s #1 Source for Repair, Sales & Service of All Industrial Electronics, Servo Motors, AC & DC Motors, Hydraulics & Pneumatics.

The broader impact of alignment management

Shaft misalignment is more than a singular mechanical issue — it’s a hidden threat to productivity and profits. Thankfully, it’s also one that’s correctable and avoidable. Precision tools, timely maintenance, and expert insights can save you from costly repairs and unplanned downtime. GES is here to offer you Repair, Sales & Service of rotating equipment, to make shaft misalignments in your factory a problem of the past.