How Industrial Motor Rewinding Extends Lifespan and Saves Costs

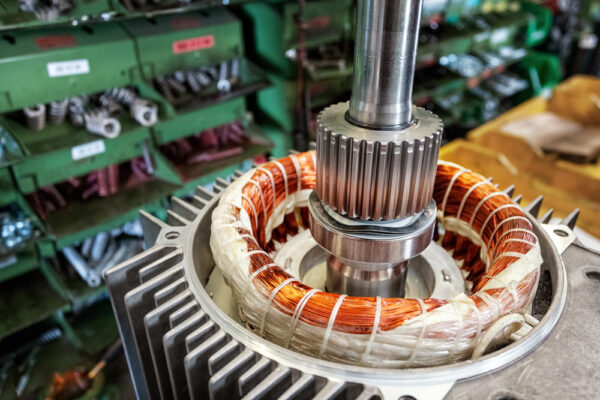

Electric motors power some of the most important equipment in manufacturing environments, driving everything from conveyor belts to ventilation systems. Over time, wear and tear can cause these motors to lose efficiency or fail entirely. Replacing them isn’t cheap, but there’s another option: motor rewinding.

Rewinding breathes new life into motors, often at a fraction of the cost of replacement. But the benefits go beyond just savings. Here’s how motor rewinding helps extend equipment lifespan — and operational budgets.

- Restoring efficiency without full replacement: When motors break down, their performance often declines due to worn insulation or damaged windings. Rewinding replaces these internal components, restoring the motor’s original efficiency. In many cases, properly rewound motors can perform just as well as new ones. In some cases, advancements in rewinding materials and techniques mean that modern rewound motors can even exceed their original performance specifications.

- Reducing long-term operational costs: While a new motor might seem like a simple fix, it often comes with hidden costs — installation downtime, configuration adjustments, and potential retrofitting. Motor rewinding sidesteps many of these challenges. A well-executed rewind not only costs less upfront but also minimizes disruption. Plus, modern rewinding techniques often improve insulation materials and winding designs, which can lead to better energy efficiency.

- Minimizing downtime during repairs: Every minute of downtime comes with a price tag. Sourcing and installing a brand-new motor can take days — or longer if it’s a specialty model. Rewinding, on the other hand, is often faster. Rewinding experts like GES offer quick turnaround times, reducing production stoppages and helping facilities get back online sooner. We offer fast 3-5-day turnaround, with rush services available.

All motors deserve proper servicing

Beyond Repair, Sales & Service of AC & DC Motors, GES is also your partner for servo motor services. Now through the end of January, contact us for servo motor repairs and get 10% OFF a single repair or 15% OFF 3+ repairs!

- Extending equipment lifespan: Industrial motors are often built to last, but over time, internal components naturally degrade. Rewinding allows facilities to extend the service life of their motors, often by years. This approach prevents unnecessary replacements and maximizes the return on investment for each motor. For older motors with high-quality materials and robust construction, rewinding is often a superior option compared to purchasing lower-grade modern replacements.

- Enhancing reliability and performance: A properly rewound motor doesn’t just restore functionality — it often enhances reliability. Modern materials and advanced techniques allow for improved insulation, better heat resistance, and better winding configurations. These improvements can result in motors that run cooler, last longer, and perform more consistently under demanding conditions.

Motor rewinding isn’t just a cost-saving measure — it’s a smart investment in equipment longevity and operational efficiency. With advancements in rewinding technologies and materials, this approach continues to deliver strong performance while reducing unnecessary expenses.

For facilities aiming to balance performance, cost, and environmental impact, rewinding isn’t just an option — it’s a strategic choice that pays off in the long run.