How Drives Are Shaping Electric Vehicle Manufacturing

The electric vehicle (EV) revolution is in full swing, transforming not just our roads but our factories too. Behind the scenes, various new-age drive types are powering the precision equipment needed to make EV production faster, more efficient, and increasingly sustainable. Here’s a closer look at the different components making EV production possible today.

OCTOBER SPECIAL: CRITICAL DRIVE REPAIRS

No matter what type of drives power your factory, they need service. Through October, GES is offering a special on AC drive repair: All month long, you can get 10% off any single drive repair or 15% off three or more repairs!

Variable Frequency Drives (VFDs): The efficiency champions

VFDs are champions of efficient EV manufacturing. By allowing motors to run at variable speeds, they can cut energy use by up to 50% in some applications. As demand for EVs ramps up among consumers, VFDs are bringing precision and energy efficiency to several critical processes:

- In battery production, VFDs control the speed of mixing and coating equipment, ensuring consistent cell quality.

- Clean room HVAC systems powered by VFDs maintain optimal air quality while slashing energy consumption.

- On assembly lines, VFDs adapt conveyor speeds to match production flow to reduce energy waste.

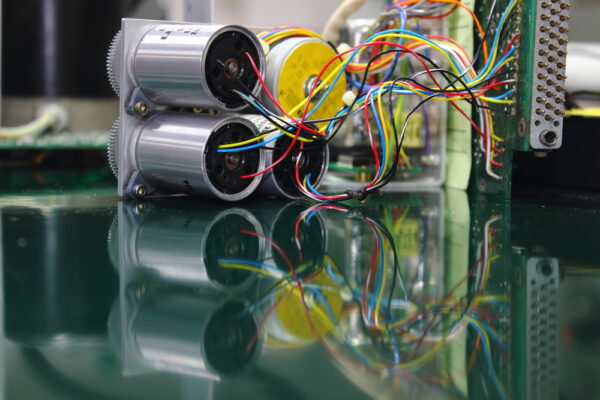

Servo Drives: Precision in motion

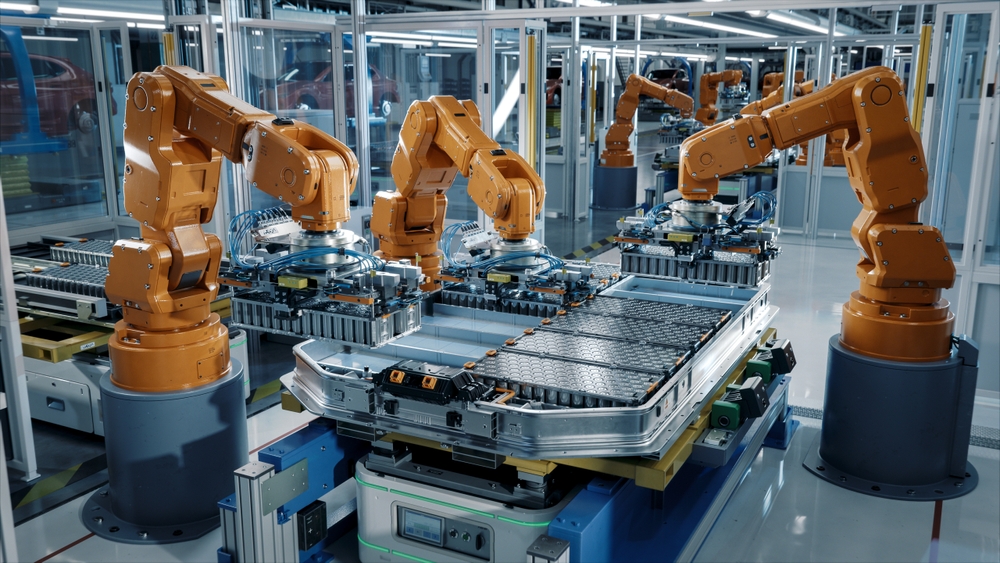

When it comes to the exacting demands of EV assembly, servo drives are powering precision processes in incredible ways. Where tolerances are tight and safety is paramount, servo drives ensure every vehicle meets exacting standards. Even more importantly, they pave the way to repeatable quality standards:

- Robotic arms equipped with servo drives achieve sub-millimeter accuracy in body panel alignment.

- In battery pack assembly, servo-driven systems precisely position and connect hundreds of cells.

- Welding and joining processes rely on the dynamic response of servo drives for consistent, high-quality results.

Motion Control Drives: Choreographing the factory floor

Complex fabrication requires coordinated movement across multiple axes. This is where motion control drives do their best work. By orchestrating complex movements with precision, these drives enable the production of intricate EV components that would be impossible with conventional methods:

- Multi-axis systems in component manufacturing synchronize motions for efficient production of EV parts.

- Cutting and forming of lightweight materials demand the precise control offered by these drives.

- Automated guided vehicles (AGVs) navigate the factory floor with grace, thanks to sophisticated motion control.

Regenerative Drives: Powering sustainability

Regenerative drives aren’t just about energy savings; they’re about rethinking how we use power in manufacturing. By recovering energy that would otherwise be wasted, these drives are making EV production greener and more cost-effective:

- Test benches for electric motors and powertrains recover energy during testing, feeding it back into the grid.

- Large press operations, once energy hogs, can now capture and reuse energy from each stroke.

- High-energy processes for quality control operate more efficiently with energy recovery systems.

The drive towards a bolder EV future

The synergy between different drive types is what makes modern EV manufacturing possible. Each plays a crucial role: from the energy-saving VFDs to the precision-focused servo drives. As demand for EVs grows among consumers, so will reliance on these drives among manufacturers. The drive revolution in EV manufacturing is just getting started — and the future looks electric.