Get the Right Repairs for Your Manufacturing Equipment

You took the motor off your assembly line. You broke it down, found the problem, and repaired or replaced the part … but the motor still isn’t working properly — even though you tested it before reinstallation. The shaft was spinning properly, so of course the motor was running properly, right?

Not necessarily.

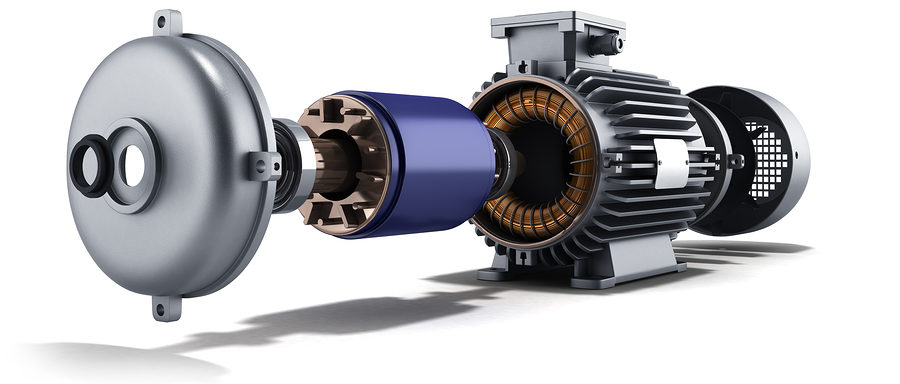

A spinning shaft is not always a good indicator of a motor’s ability to function. Load testing motors with a dynamometer can provide a better picture of repair effectiveness and identify weak spots. Here’s why:

All problems have been fixed

After calibration, issues such as vibration, thrust, torque, startup, and voltage require attention. For example, shafts can still spin even if winding insulation resistance is weak. But weak motor coils will fail when you put a load on the motor sometimes with simple shortages and others with catastrophic overcurrent. Load testing ensures the motor is functioning properly at its highest rated capacity so reinstalled motors won’t cause future problems.

Generally speaking, motors are only parts of larger systems. Load testing provides torque, creating the type of resistance that motors experience when working with other moving parts.

Save money and improve productivity

Faulty motors cause equipment downtime and can be expensive to repair. Improper repairs incur even more costs as you hire technicians to remove, check, and repair motors again. All this time, you’re unable to use the equipment, losing valuable human hours and productivity. Load testing ensures motors are ready for you to put back into action immediately so you only pay for one repair and reduce downtime.

Remove the gremlins

How often have you had a customer or one of your own equipment operators describe a problem but be unable to replicate the issue? Intermittent motor failures are the most difficult repair because it’s difficult to pinpoint exact issues. Load testing puts motors through their paces, enabling you to replicate whatever conditions caused intermittent failures. Once you can replicate them, you can fix the issues.