Flow Meter Measurement Errors

In a piping system, it is essential to have a measuring feature in place to determine the rate at which fluid or gases will travel through the system. With a water system, for example, you would want to know the volume of water that passes from one point to another in one second.

With flow meters, you can set a budget and determine the flow of a healthy, fully functioning system. If you get a flow meter error or see some irregularity in the control flow rate, you should take these as warning signs of problems with the system’s health.

What Is a Flow Meter?

A flow meter is an instrument that measures the rate at which gas or fluid passes through a piping system. As the fluid crosses the location of the meter, the device measures the fluid volume each passing second. The purpose of this is to determine how much fluid will pass through the system at any given time.

Several different types of flow meters carry out the process in slightly different ways. A common variety of flow meter is the paddlewheel, in which the flow of fluid in a pipe activates the wheel. Magnets embedded into the paddle act as sensors of the flow volume. As the fluid passes across this point, the device generates pulses to monitor the flow of any liquid.

In a variable area flow meter, the flow rate changes as fluid passes through different-sized areas. In a positive displacement flow meter, fluids get trapped and passed along counter-turning rotors. The flow rate determines the velocity of the rotors, and therefore serves as a basis for the measures.

Common Causes of Flow Meter Errors

Many things can happen inside a flow meter that can cause the measurements to go askew. Some of these problems are due to internal buildup that slows down the flow of fluid. Other problems result from changes in velocity, caused by external pressure or abrupt movements. The following issues are the nine most common disruptive factors in a meter’s accuracy.

1. Scaling

One of the worst problems that can adversely affect the measurements of a flow meter is scale, which refers to the buildup of mineral deposits along the interior walls of a piping system. The deposits stem from impurities within the fluid passing through the flow meter.

Examples of scale include buildups of sodium, calcium and magnesium, which can slowly accumulate within the pipes as particles from these minerals separate from the fluid and form gunk along the inner tubes. Scale is one of the inevitable problems that can accumulate over time when unfiltered fluid enters a piping system.

Scaling is troublesome for flow meters because the purpose of the function is to read the average rate at which fluid passes from point A to point B in a piping system. When scale is present, it slows the entire flow of fluid to an unnatural pace due to a narrowing within the tubes, which causes less space for the fluid to pass.

The problem can become worse if the scale gets dense in certain spots and begins to flake off and send chunks through the system. On certain types of flow meters, scale can even interfere with the measuring components and further skew the accuracy of the readings.

2. Sludge

Another problem that can impact the accuracy of a flow meter is sludge, a self-explanatory word for any kind of grimy foreign matter that enters into a fluid stream and hampers the flow. Sludge can emerge from oils and dirt that enter the fluid. As the elements coalesce into sludge, it can negatively affect flow readings.

Sludge can also result from grains emitted from grinding components. For example, if the flow meter reads the passage rates of fluids that have already been through rotors and other grinding parts, metal particulates can break free from these components as a result of the grinding motions. Once these particles mix with other impurities, sludge can coalesce within the fluid.

The worse effect of sludge is the slowing effect it has on the flow of fluids in a piping system. As the fluid becomes thicker and less consistent due to foreign matter, a flow meter can’t provide accurate readings.

The problem can be even more severe if scaling is also plaguing the piping, which can cause the passages to narrow and further restrict the flow of fluids. In many cases, scale results from sludge or vice versa.

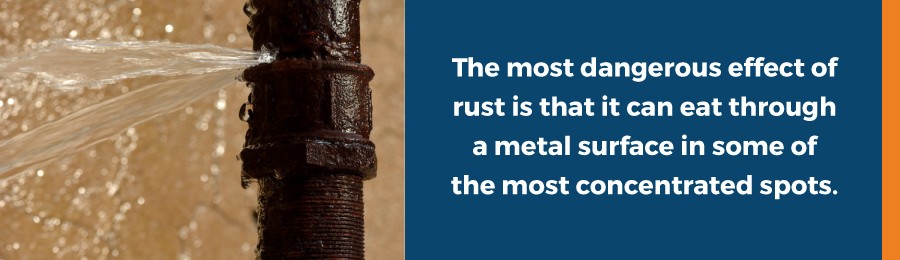

3. Rust

Rust is the enemy of all metal. In a metal piping system, rust can form if an element passes through the fluid and has a corrosive effect on the interior lining. Corrosion is one of the inevitable consequences that comes into play when an untreated metal component will contacts both air and liquid.

As rust forms along the interior walls of pipes, particles of rust can flake off and pass through the fluid. As these particles accumulate, the effects can hamper the readings of the flow chart due to the slowed passage of fluids through the system.

The most dangerous effect of rust is that it can eat through a metal surface in some of the most concentrated spots. Along the parts of a metal piece where remaining wetness evaporates into the surface, rust can ultimately take root on those spots and gradually eat through the metal.

The use of chemicals in the fluid stream can inhibit corrosion, but these are not foolproof. If the system has a passage where the fluid flow is low and air enters the system, the combined effects of liquid and air exposure can open the affected metals to the development of rust.

4. Slime

In a piping system, slime is any living matter that comes into being through developments in the water. Examples include algae and microorganisms, which can coalesce in certain fluids. Slime has a similar effect to sludge in a piping system due to the thickness it brings to the passage of fluids.

Slime has earned a reputation for its gooey quality and consistency, which typically feels like jelly and tends to flow through piping systems at slower rates than looser fluids. Consequently, a system plagued with slime will typically have inaccurate readings on the flow meter.

While the flow of slime is generally slow, it leaves minimal trace along the interior walls of a piping system due to its softness. However, if scale is already a problem in the pipes, the slime could leave traces that might stick to the gunk and accelerate scaling inside a set of pipes.

Slime is mostly a nuisance that causes fluids to slow and is therefore bad for flow measurements. However, slime could also result in clogging in a piping system that contains sharp turns and siphons.

5. Slurry

Slurry forms when tiny solid particles coalesce within the fluid stream and cause a thickening of the overall flow. In a piping system, this can gradually cause the flow of fluids to slow within the pipes and lead to skewed measurements on the flow meter.

Slurry containing tiny pieces of hard particles can have an abrasive impact as it passes through the system. As these rough particles pass along the pipe lining, the piping could gradually become scratched and compromised.

Slurry can slow down the flow of liquids in any piping system, especially if the piping layout contains sharp angles between the start and finish points. On certain flow meters, slurry can even impact the measuring components and further hasten damage to the system overall.

Slurry is similar to slime and sludge in that it acts as a thickening agent within a fluid stream. Unlike slime, however, slurry tends to be more abrasive because it consists of tiny particles of metals and other hard materials. Therefore, slurry can act as a flow inhibitor and also have a damaging impact on the health of metal and the structure of pipes, much like rust.

6. Air Bubbles

Another irregularity that can impact a flow meter is the presence of air bubbles in the fluids that pass through a piping system. Air bubbles can result from the entrance of air into a set of fluid pipes. This issue sometimes happens at the entry points of certain systems that don’t have airtight components.

Air bubbles are detrimental to the flow of fluid in any system where the meter measures the flow of carbon-free fluids. Flow meters are designed to measure the volume of fluid as it passes across a certain point in a piping system. When bubbles are present, they significantly reduce the volume of the fluid itself. Consequently, air bubbles cause inaccurate flow measurements.

The presence of air bubbles can also adversely affect the components of certain types of flow meters. In a vortex flow meter, for example, air bubbles can violate the formation of Karman vortices. In an ultrasonic flow meter, bubbles degrade the generation of ultrasonic waves.

7. Flow Deviation

In a piping system, flow deviation can occur when the passages contain angles, siphons and other curves that can impact the velocity of passing fluids. As long as the fluid passes through a straight and horizontal set of pipes, the fluid velocity will generally flow at a uniform rate. Once the fluid passes through a sharp angle or vertical pipe, the velocity will inevitably change to some degree.

In a piping system designed with these irregularities in mind, the flow readings are usually acceptable at face value, since the velocity could speed or slow within a certain range of variation at any given time. The real problem is when the system designer fails to factor irregularities into the equation, and the person reading the meter accepts flow measurements for what they are, according to the standards of a straight and horizontal fluid velocity.

Differences in piping circumference along the length of a piping system also cause irregularities. If the fluid passes through one set of pipes that connect to a narrower link, the fluid will inevitably slow through that link, as the pipe in question will lack the space to pass the same volume of fluid as the corresponding pipes.

8. Pulsating Flow

In a piping system, pulsations are instantaneous accelerations in flow. As fluid passes through a piping system, a pulsation could lead to an inaccurate flow measurement due to the momentary change in velocity. A pulsation might occur at irregular intervals and send fluid passing faster under the flow meter. Pulsations are a regular occurrence in systems that use piston pumps.

In a piping system, consistency in flow is one of the most crucial assets for reliable measurements in a flow meter. If you even have one pulsation during a given period, it could affect the overall average and give a false impression of the volume of fluid that passes through the system.

Pulsations are similar to deviations, as both affect the velocity of passing fluids. Unlike deviations, which are generally the result of system design and layout issues, pulsations are due to rough, sudden impacts on the fluid flow.

If a pulsation occurs only once or twice during a given span, the difference will likely stand out in a log of flow measurements. If the other measurements are uniform, you could trust those as accurate and discard the outliers, but also take note that the system could have a pulsation issue.

9. Piping Vibration

In a piping system, vibration occurs when a sequence of pipes makes shaking motions. This phenomenon can occur at any time due to various internal and external factors. If the piping vibrates as fluid passes across the flow meter, the irregular movements could easily skew the volume measurements.

Even though variations caused by vibrating activity are usually subtle, they are not insignificant due to the preciseness of flow meters. Even a faint vibration could set a measurement off and give an inaccurate impression of a system’s flow potential.

The problem with vibrations is that they cause passing fluids to move up and down and side to side. Movements such as these can corrupt the flow in a system designed to move fluid forward. The purpose of a flow meter, after all, is to measure the volume of fluid flow at a forward trajectory. Rattling movements of any kind can give a false impression.

Vibration is problematic in Coriolis and Karman flow meters, whose design does not allow them to measure flow with any irregularities. Vibration is generally a non-issue with electromagnetic and ultrasonic type flow meters, which remain unaffected by these types of motions.

Flow Meter Repairs at Global Electronic Services

When you spot irregularities in the control flow rate of a system, you should have the issue rectified before the matter spirals out of hand. If the problem accelerates, you could face a more severe set of repairs in the future. Contact Global Electronic Services for more information on flow meter repair.