What Ever Happened to 3D Printing at an Industrial Scale?

Just last month, Wired magazine published a feature article with the headline “3-D Printing is the Future of Factories (For Real This Time).” While it’s something of a sensationalist headline, it does beg the question: What happened to the original 3D printing revolution of just a few years ago? The answer is a tale of two unique problems.

The first and biggest issue to stunt industrial 3D printing growth was the lack of material technologies available. Simply put, for factories to produce 3D-printed metal components, they needed machines that were able to work with molten metal. And, considering most metals have melting points of thousands of degrees, the idea of a machine being able to melt and extrude them was pretty much dead on arrival.

The other chief issue with industrial 3D printing was the lack of demand for products that could be printed at high volumes. Most often, these were knickknack items that manufacturers could just as easily — and more cheaply — produce with injection molding technologies. With profit margins already razor thin, it just didn’t make sense for companies to 3D print using metal.

So, by way of technologies that were not viable and products no one really wanted, the industrial 3D printing craze died almost as quickly as it flashed into being.

The 3D printing space today

Industrial 3D printing isn’t entirely gone, however. In fact, its lackluster showing in the manufacturing sector actually translated into other niches where it has become wildly successful — including 3D printing for medical devices. 3D printing has evolved to be a complement to industrial manufacturing and today also occupies a large space in the prototyping industry. The quickness and convenience of 3D extrusion allows developers to bring complex prototypes to life in tangible forms without requiring any tooling or specialized dies.

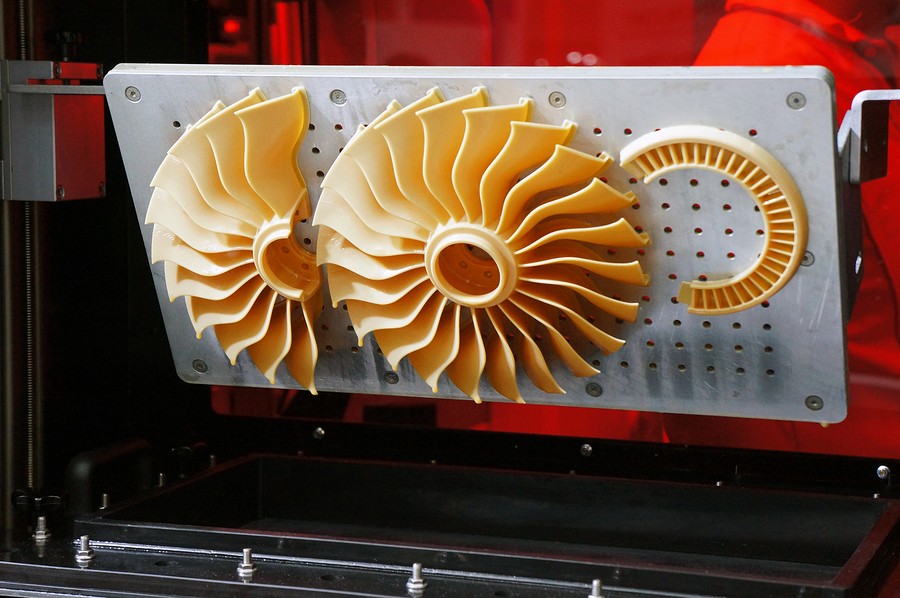

Some specialized manufacturing processes also benefit from 3D printing solutions, although they’re fewer and further between. One example is GE’s turbine manufacturing division, which uses Electron Beam Melting (EBM) machines to fuse metal powders into precision components. This method — which is different from the traditional heating and extrusion method we’ve come to associate with 3D printers — is a complex form of industrial 3D printing that’s reserved for limited manufacturing runs and companies able to afford the machines’ million-dollar price tags.

Tomorrow’s 3D printing potential

So, what exactly is Wired talking about when they advertise the “real” future of industrial 3D printing? The buzz is on a new type of 3D printing and a proprietary process called sintering.

Coined by the veritable grandfather of 3D printing, Ely Sachs, sintering is a process that combines metal powders with a binding agent then heats them into a fusion. The binding agent, usually a polymer, hardens and, when heated in an oven, works to fuse the metals together before the agent burns away. The result is a single fabricated component. In the same way GE’s EBM machines are a departure from our standard concept of 3D printing, the sintering process is another innovation making industrial 3D printing more viable.

Thanks to innovations in machinery and the availability of metal powders, sintering is rapidly becoming a possibility for mass-produced 3D printed parts and components. And with it comes a reignited potential for large-scale industrial 3D printing as the future of manufacturing. Will it pan out? Only time will tell!