ERP Trends Point to a Leaner Future for Many Manufacturers

Every manufacturer practices Enterprise Resource Planning (ERP) to some degree. Whether it’s a cost-benefit analysis before upgrading equipment or creating a full digital twin of your asset to monitor its service record, you need a granular look at what it means to own and maintain critical assets for the life of the equipment. How much did maintenance cost last year? What’s the ROI of your investment to date? How many more years of effective use will you get out of it? ERP answers these questions and dozens more.

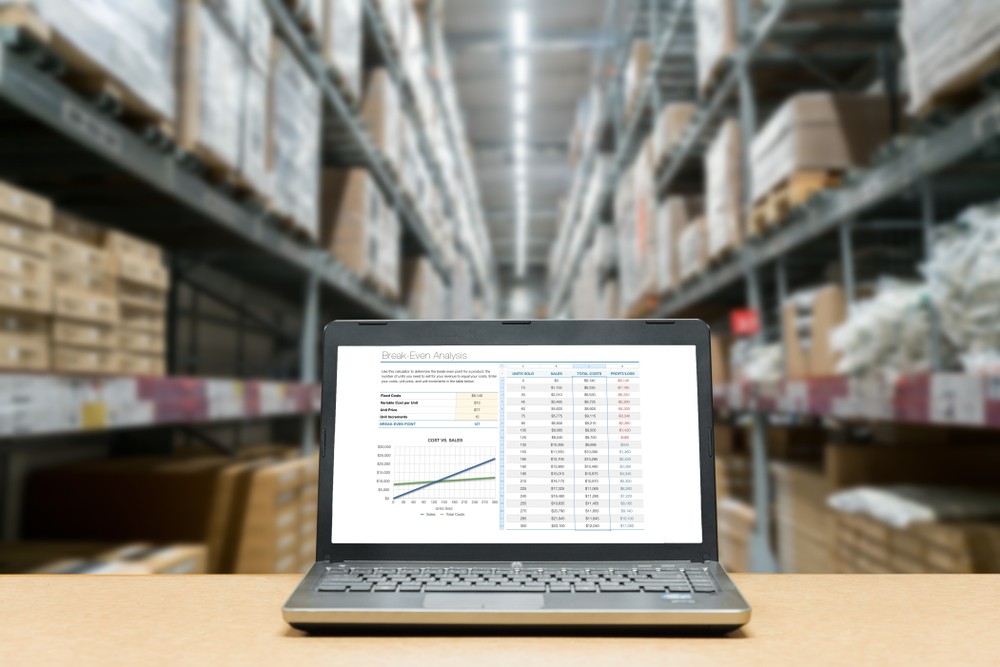

ERP software is a manufacturer’s best tool for managing assets. But it’s not often the most accessible. Legacy platforms are expensive and meant for enterprise companies, while smaller platforms don’t always offer the resources to effectively visualize an asset’s life cycle. Many small manufacturers still approach ERP with spreadsheets and printouts. Thankfully, we’re on the cusp of a new era.

Technology is driving ERP solutions to be better

ERP is important because it keeps manufacturers in-the-know about their most critical resources and assets. The more data you have about essential assets, the better you can manage them. It all trickles down into a leaner approach to maintenance, repairs, and capital expenditures.

As small-to-medium-sized manufacturers look to assume leaner operations, technology is the key. Now, technology has finally caught up to ERP demands. The result is prevalent in some game-changing trends that are exciting for manufacturers of all sizes:

- Open APIs and iPaaS solutions. For manufacturers with legacy applications or data siloed by closed-application ecosystems, ERP is getting easier. Open APIs make it simple to connect apps and aggregate data into dashboards and channels explicitly for resource management. For software that still doesn’t play nice with others, integrated platform-as-a-solution (iPaaS) systems help to de-silo data and make it available.

- Cloud-based ERPs. A new wave of ERP software is slowly displacing entrenched legacy options, while simultaneously making it easier for smaller manufacturers to digitize their currently manual ERP process. Cloud-based systems are making it easier to take a broad approach to asset management across different facilities or segments of the business.

- Servitization and SaaS models. New innovations like machine learning make it easier for ERP managers to do their jobs. These innovations are generally packaged with a platform and offered as software-as-a-service (SaaS) or as part of a servitization model. For many smaller manufacturers, the ability to offload ERP to an automated system or a contracted partner is a weight off their shoulders.

- Simplified ERP. In a world of big data, simplicity is something every manufacturer cherishes. Simplified ERP is a good place to start. Instead of deciphering complex data to make precise decisions about what to do and when, simplified ERP systems rely on smart technologies and integrated systems to tell you when and how to act. Whether it’s one machine or a fleet of equipment, these systems take the guesswork out of ERP.

Each of these trends paves the way for opportunities in ERP — opportunities that many manufacturers need to seize in the current economic climate.

Leaner ERP is on the horizon

Perhaps the biggest benefit of modern ERP solutions is their affordability. ERP is all about optimizing the return on capital investments and ensuring maximum utilization of the assets at your disposal. The latest trends in ERP emphasize this within the framework of a lean mindset. For companies that embrace new ERP opportunities, the benefits are compounding.