Embrace the Repair Movement At Home and In Your Plant

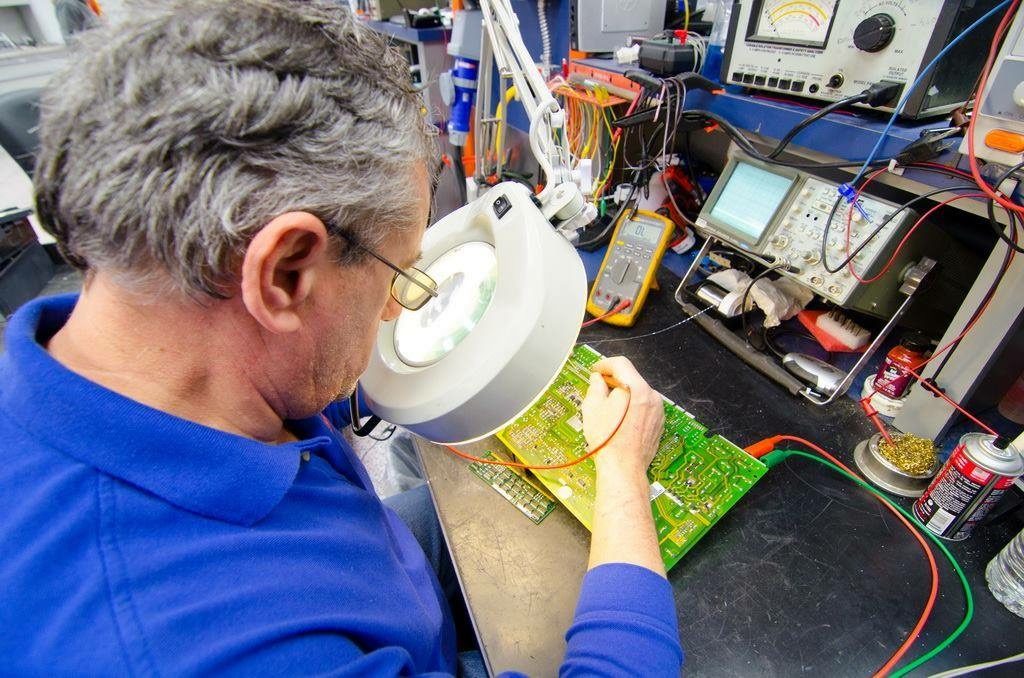

From small-scale electronics to larger manufacturing industries, people are taking note of the environmental and financial burdens of electronics waste. A growing repair culture draws further attention to these issues as insiders work toward widespread support for those who prioritize repair and reuse over filling landfills with expensive — and often perfectly good — electronics.

The trend toward disposable electronics has had an immediate, noticeable effect on the environment. Electronics companies that withhold repair instructions or parts, release software updates that render useable electronics obsolete, or deliberately make new models more affordable and accessible than repair all contribute to rising toxic waste levels in landfills.

The trend toward disposable electronics has had an immediate, noticeable effect on the environment. Electronics companies that withhold repair instructions or parts, release software updates that render useable electronics obsolete, or deliberately make new models more affordable and accessible than repair all contribute to rising toxic waste levels in landfills.

According to a United Nations Environment Program report, people will dump an expected 50 million tons of electronic waste in 2017 alone. These materials contain mercury, lead, silver, and flame retardants that contaminate the ground and water as well as pollute the air when trash is burned. The demand for fast, cheap replacements is also contributing to pollution in the form of mining and material production.

There’s a new trend growing from this realization: A repair culture aims to fight back against the wastefulness of the electronics world. Considered an offshoot of the maker movement, these repair advocates organized and formed The Repair Association. Repair professionals, individuals, as well as trade association and environmental advocacy agency members comprise the group. They aim to take the monopoly on repairs out of the hands of big companies and give people the right to repair their own electronics or hire trained repair personnel to do the work.

![]() Many repairs are blocked by digital locks, copyrighted software, and restrictive user agreements. Often, repairs require proprietary tools or instructions not available to the public. Therefore, those in the repair movement have been pushing manufacturers to sell replacement parts as well as diagnostic and service manuals. So far, large corporations like Apple have lobbied to kill the bills, but repair advocates are making progress.

Many repairs are blocked by digital locks, copyrighted software, and restrictive user agreements. Often, repairs require proprietary tools or instructions not available to the public. Therefore, those in the repair movement have been pushing manufacturers to sell replacement parts as well as diagnostic and service manuals. So far, large corporations like Apple have lobbied to kill the bills, but repair advocates are making progress.

It’s difficult to entice leaders of large companies away from systems that work so well for them, but there are potentially attractive benefits for those who embrace the repair movement. In Sweden, the government introduced tax breaks on repairs to old items — not just electronics — to discourage the trend of trashing something and buying new. They’ve found that this has resulted in a burgeoning repair industry and considerable job creation. In addition, their waste and carbon emission reduction has gone beyond a domestic advantage and become a truly global benefit.

Industrial recycling practices often revolve around data protection and a few hazardous chemicals, but those in the manufacturing industry can benefit economically from a robust recycling and repair plan that’s part of a larger sustainability effort. GE is a leader in this area, doing it in part because it makes good business sense.

Industrial recycling practices often revolve around data protection and a few hazardous chemicals, but those in the manufacturing industry can benefit economically from a robust recycling and repair plan that’s part of a larger sustainability effort. GE is a leader in this area, doing it in part because it makes good business sense.

As governments take steps in regulating environmental protections, manufacturers can develop sustainability practices that will likely result in immediate and long-term economic gains.

The professionals at Global Electronic Services believe in repair benefits and have built a business dedicated to helping you maintain the equipment in which you’ve invested. Our team of experts can meet all your industrial electronic, servo motor, AC or DC motor, hydraulic, or pneumatic repair needs. Contact us for more information about how we can help you keep your equipment running and out of the landfill.

The professionals at Global Electronic Services believe in repair benefits and have built a business dedicated to helping you maintain the equipment in which you’ve invested. Our team of experts can meet all your industrial electronic, servo motor, AC or DC motor, hydraulic, or pneumatic repair needs. Contact us for more information about how we can help you keep your equipment running and out of the landfill.