Diagnosing and Repairing Short Circuits in Industrial PCBs

Short circuits are one of the most common failure modes in industrial PCBs — and one of the most time-consuming to diagnose. They can bring down entire systems in seconds, but finding the source often takes much longer. Unlike open circuits or failed components, shorts don’t always leave visible damage. You won’t notice burn marks or cracked solder — just a board that won’t power up, a line that keeps tripping, or a fuse that keeps blowing.

Without a clear path, the only option is to trace it — carefully, methodically, and with the right tools in hand. Because once current flows where it shouldn’t, it’s not just a component at risk. It’s everything connected to it.

Not all shorts are obvious

Some shorts leave scorch marks. Others just leave more quiet clues. Sometimes, the symptoms are subtle. Boards may function intermittently. Other times, they fail silently under load. You might get a blown fuse and nothing else. Or a voltage rail that reads low with no visible fault. The best approach? Always assume the short is there until you can prove otherwise, and recognize the common signs that point toward one:

- Immediate power loss or tripped protection circuits

- A component heating rapidly on startup

- Low resistance across a power rail

- Physical damage like burn spots, lifted pads, or cracked ICs

How to track the problem down faster (and smarter)

Patience helps in these situations. So does a methodical plan:

- Start with a visual inspection: Look for discolored components, warped PCB sections, or cracked solder joints. It won’t catch everything, but it might catch enough.

- Check for resistance across power rails: A dead short will usually show up as a near-zero resistance reading between power and ground.

- Use thermal imaging or freeze spray: Shorts often generate heat. Infrared cameras and freeze spray can help pinpoint hot spots — especially during power-up.

- Apply low-voltage current tracing tools: These inject a controlled current into the board and detect magnetic fields created by the fault. It’s a precision approach with minimal risk of further damage.

- Lift components as a last resort: If nothing else works, start lifting power-hungry ICs or decoupling caps. But do it in reverse order of likelihood — start with passive components before removing expensive chips.

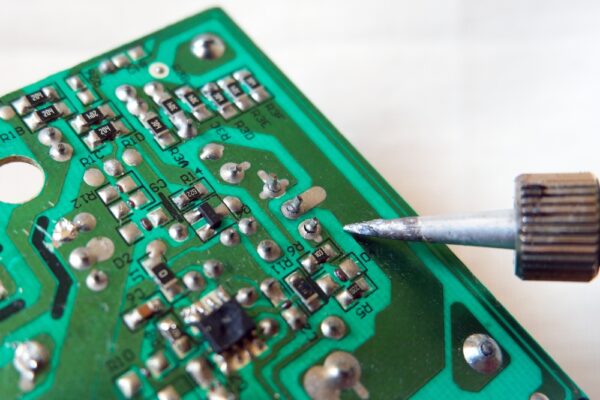

Fixing the damage without making it worse

You’ve found the short. Now the real work begins.

- Remove and replace damaged components: Burnt resistors, cracked diodes, or blown ICs need to go. Replace them with spec-matched parts, not “close enough” substitutions.

- Repair lifted pads or traces: Use fine-gauge wire or jumper techniques to restore connectivity. Double-check insulation and spacing — especially in high-voltage sections.

- Clean the board thoroughly: Flux residue or conductive debris can trigger future shorts. Use proper PCB-safe solvents and avoid shortcuts.

- Re-test under load conditions: Don’t just check continuity. Run the board under expected voltage and current levels to confirm stability.

Shorts don’t happen in a vacuum

A failed component might be the victim, not the cause. If you only fix the symptom, the short will come back — or worse, take out more of the board. That’s why a full diagnostic matters. Check input voltages, measure heat dissipation, and inspect related circuitry. Every short has a backstory. Miss it, and you’re on borrowed time.

With the right tools, knowledge, and repair process, even the most elusive board-level fault can be resolved. The team at GES combines advanced diagnostic methods with real-world repair skill to uncover, fix, and future-proof your electronics — fast. Send us your PCB repair today and take advantage of 10% OFF single repairs or 15% OFF 3+ repairs on ABB products, now through the end of the month!