COVID-19 is Accelerating These 3 Industry Trends in a Major Way

Manufacturing is facing a myriad of challenges all at once. COVID-19 still looms large over the industry, as do trade tensions and political uncertainties. Together, these forces are bearing down on domestic producers, requiring time, money, and strategy to solve. But as the old saying goes, necessity is the mother of invention — or in this case, innovation. To combat new challenges, manufacturers are turning to new trends — trends that are rapidly shaping the future of domestic manufacturing.

While COVID-19 and other headwinds depress some facets of industry, here’s a look at three trends accelerating in these turbulent times.

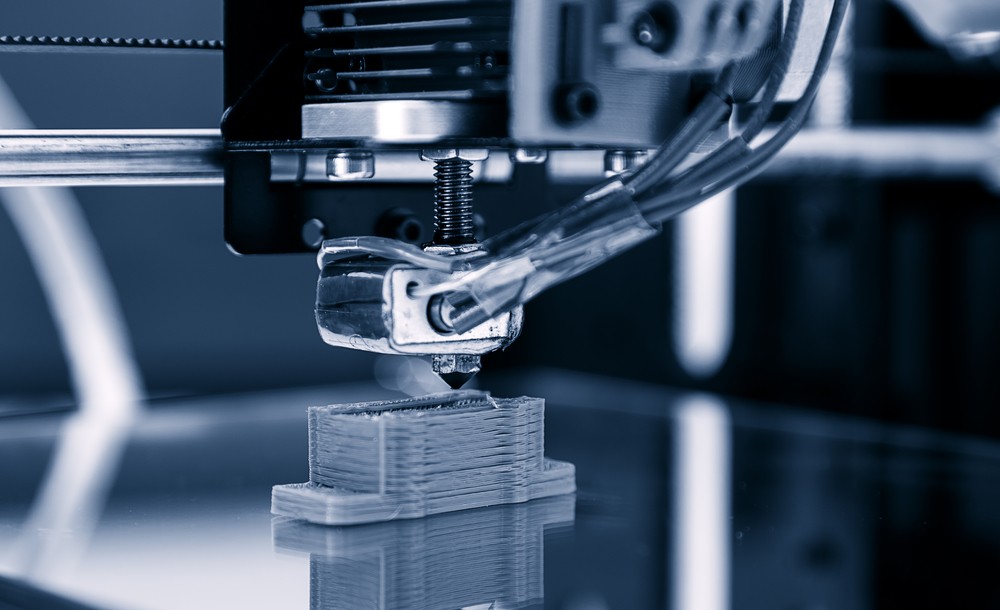

1. Additive manufacturing

Additive manufacturing has long been one of those trends that’s “almost there.” COVID-19 might just be the catalyst that pushes it over the hump and into the mainstream. Why? Because of the autonomy of the process.

Additive manufacturing — like CNC machining or robotic-powered processes — has the potential to be a ‘set it and forget it’ resource. In a time when factories are staffing light and social distancing, additive manufacturing is the perfect solution to keeping workplace staffing slim and safe. 3D printing and other additive manufacturing processes are growing in so-called ‘dark factories:’ plants where skeleton crews rely on automation to yield results.

Sintering and other additive metallurgical processes are still on the cusp of major adoption, but they’re gaining traction quickly as factories pivot to anticipate long-term trouble from COVID-19. 2021 and beyond may finally give way to the rise of 3D printing at-scale.

2. Decentralized manufacturing

Prior to the First Industrial Revolution, production came from cottage industries — at-home production of goods in literal cottages. Today, we’re seeing shades of this same concept, readapted for a different era. This time, it’s called decentralized manufacturing.

The concept is simple: assemble individual components in many locations, ship them all to a single location, and assemble the final product. It’s a practice perfectly suited to the COVID-19 climate and one that’s quickly gaining traction in manufacturing sectors like apparel and consumer goods.

There are limits to decentralized manufacturing — namely when it comes to proprietary components, volatile materials, and items difficult to transport. It’s a practice best suited to simple assemblies. And in manufacturing sectors where it’s applicable, it’s a trend on the rise, growing stronger the longer COVID-19 lingers.

3. Reshoring

The disarray facing supply chains has every manufacturer looking for ways to create stability. For many, it means playing procurement closer to the chest — moving away from an offshoring model and reshoring supply chains.

Reshoring in the current climate has many advantages. Not only does it give manufacturers more control over sourcing and procurement, supply times are often expedited. Pricing for parts and materials also is generally more predictable and steady in a domestic market. On the production side of things, intellectual property (IP) theft becomes less of a concern when the process is on American soil.

As supply chain woes continue and manufacturers seek more stability in their procurement, expect reshoring to continue. Although there are significant logistical challenges to reshoring, many manufacturers are taking proactive action to create certainty as part of a fallback, instead of facing potential fallout as COVID-19 continues to impede global initiatives.

Will these rapidly rising trends continue in a post-COVID-19 world? It’s very likely, as their momentum continues, that these trends herald the next phase of a shifting manufacturing environment.